Composite lining for large-deformation surrounding rock section

A compound, large-deformation technology, applied in the shaft lining, tunnel lining, climate change adaptation, etc., can solve the problem of not being able to fully utilize the self-bearing capacity of surrounding rocks, not being able to reflect the combination of rigidity and flexibility of the support structure, and not meeting the principle of timeliness and other issues, to achieve light weight, convenient and quick construction, and improve the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

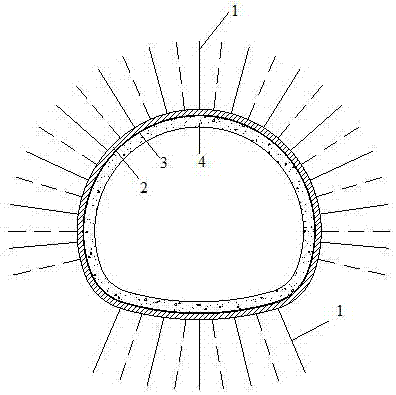

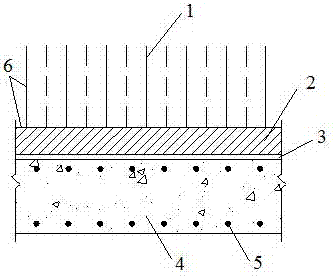

[0021] Embodiment 1: as Figure 1~2 Shown: a composite lining of a large deformation surrounding rock section, the primary support 6, the waterproof board 3 and the PVA-ECC secondary lining 4 are sequentially arranged along the radial direction of the tunnel from outside to inside; the primary support 6 is made of glass The fiber anchor 1 and the PVA-ECC spray layer 2 are composed, and steel mesh can be hung, steel arches, etc. can be installed according to the needs; the PVA-ECC secondary lining 4 is provided with longitudinal and circumferentially distributed steel bars 5, which can be adjusted according to the stiffness Steel arches and the like need to be added; the waterproof board 3 is located between the primary support 6 and the PVA-ECC secondary lining 4 .

[0022] The glass fiber anchor rods 1 are symmetrically arranged in the tunnel arch and side walls in a quincunx shape, and are arranged in the inverted arch to resist the pressure of the floor drum. The glass fib...

Embodiment 2

[0023] Embodiment 2: The construction technology of the composite lining of the large deformation surrounding rock section in the present invention is the same as that of the conventional composite lining structure; the PVA-ECC spray layer 2 is formed by spraying PVA-ECC material, and the PVA-ECC The secondary lining 4 is poured with PVA-ECC material, and the components of the PVA-ECC material are cement, fly ash, sand, water, water reducing agent and PVA fiber, wherein, in terms of mass ratio, cement: powder Coal ash: sand: water: water reducing agent = 1: (1.0~1.2): (0.6~0.8): (0.42~0.57): (0.001~0.003); mixed with cement, fly ash, sand and water reducing agent The total volume after uniformity is the base number, and the dosage of PVA fiber is 13~20kg / m 3 . The cement is P.O.42.5 Portland cement, the fly ash is first-grade fly ash, the particle size of the sand is 0.2mm~0.4mm, the length of the PVA fiber is 12mm, the diameter is greater than 30μm, and the anti- The tensil...

Embodiment 3

[0030] Embodiment 3: The components of the PVA-ECC material in this embodiment are cement, fly ash, sand, water, water reducing agent and PVA fiber, wherein, by mass percentage, cement: fly ash: sand: water: Water reducer=1:1.2:0.72:0.57:0.003, based on the total volume of cement, fly ash, sand and water reducer evenly mixed, the mass content of PVA fiber is 20kg / m 3 . The cement used is P.O.42.5 Portland cement; the fly ash is first-class fly ash; the particle size of the sand is 0.2mm~0.4mm; the PVA fiber is a fiber produced in Japan, the length is 12mm, the diameter is 39μm, and the tensile strength It is 1620MPa, the modulus of elasticity is 42.8GPa, and Sika polycarboxylate superplasticizer is added. Its mechanical properties test and results are as follows:

[0031](1) A prism test block of 100mm×100mm×300mm was used, and the axial compressive strength test was carried out after 28 days of curing according to the standard curing method. The test results show that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com