Whole body embedded type rigid pedestal and construction method thereof

An embedded and rigid technology, applied in infrastructure engineering, construction, etc., can solve the problems of weak overall rigidity and the inability to achieve complete consolidation of the column foot, reducing the embedding depth, expanding the effective bearing area, and improving the economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

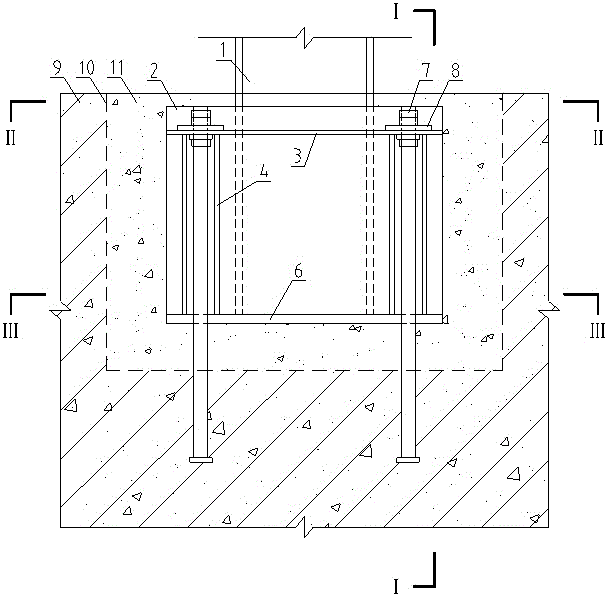

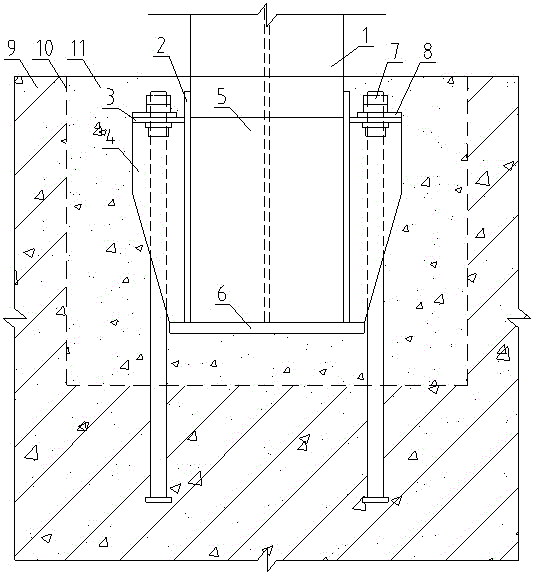

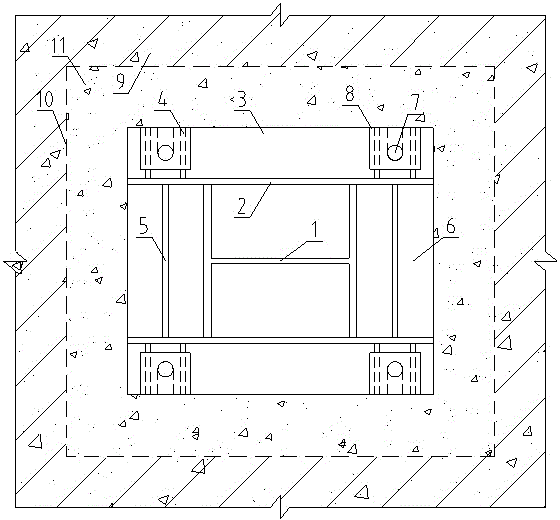

[0021] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0022] Such as Figure 1~4 As shown, an integral embedded rigid column base includes a steel column 1 and an anchor bolt 7, the bottom of the steel column 1 is welded with a column base plate 6, and the lower part of the steel column 1 extends into the groove of the reinforced concrete foundation 9 and embedded in the post-cast concrete 11, the embedded steel column 1 is partially symmetrically arranged with two shoe beams 2 parallel to the web of the steel column 1 and close to the same side of the two flange plates of the steel column 1, the shoe beams 2. The inner side is welded to the corresponding sides of the two flange plates of the steel column 1. The bottom of the shoe beam 2 is welded to the bottom plate of the column foot 6. A basic protective layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com