Giant cruciform combination column and manufacturing method thereof

A manufacturing method and technology of combined columns, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of inconvenient transportation, high construction surface requirements, and difficult on-site processing, etc., and achieve convenient cross construction, reduce the weight of the structure, and reduce assembly work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

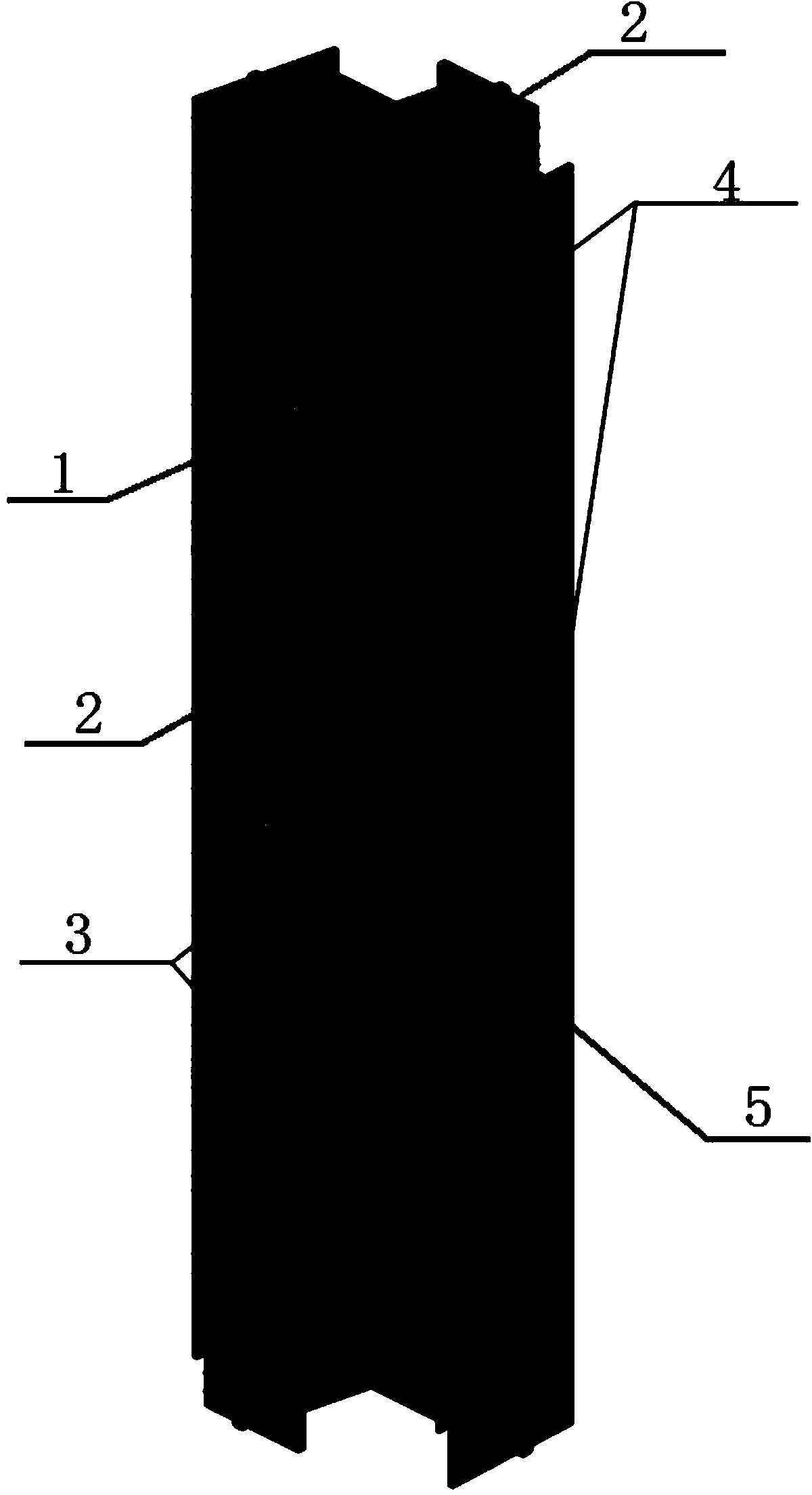

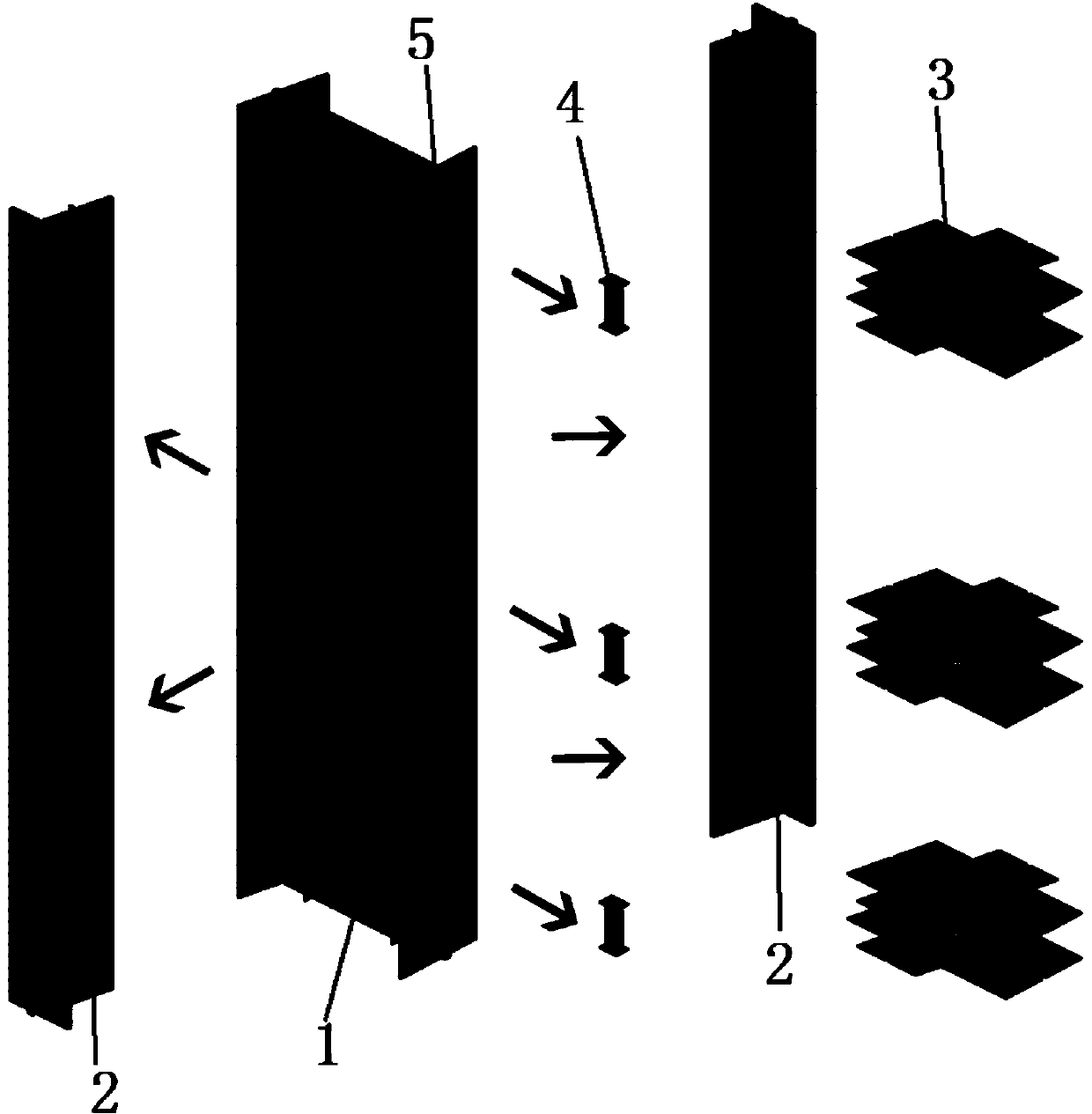

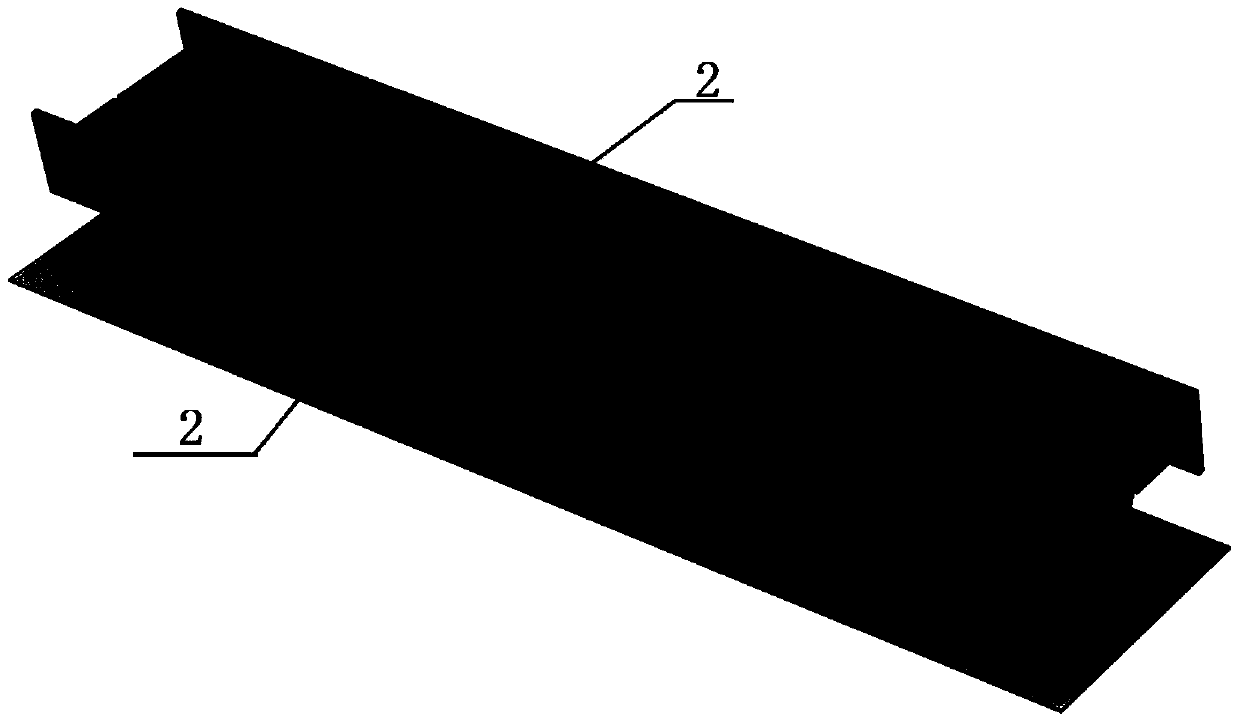

[0034] Example 1: like figure 1 and figure 2 The giant cross composite column shown includes two pieces of T-shaped steel 2 and one piece of I-shaped steel 1; T-shaped steel 2 is installed on both sides of I-shaped steel 1 to form a cross-shaped column structure with side plates, and two T-shaped steel 2 plates The included angle between them is 1.5 degrees; there are two layers of stiffening plates 3 on the top, middle and bottom of the column structure, studs 5 are set on the side plates of the column structure, and the stiffening plates 3 on the I-beam 1 The connecting part is provided with corbel 4.

[0035] The column structure is made of a steel plate with a thickness of 45mm and a material of Q345GJC-Z15 and a steel plate with a thickness of 60mm and a material of Q345GJC-Z25.

[0036] The manufacturing method of the above-mentioned giant cross combined column specifically includes the following steps:

[0037] (1) Use a 2000-ton hydraulic press to level the I-bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com