High-speed jacking and transferring control method

A technology of lifting, transferring and controlling methods, applied in the direction of conveyor control device, conveyor, roller table, etc., can solve the problems of unfavorable sorting accuracy, high installation accuracy requirements, small operating space, etc., and achieve belt replacement. Convenience and efficiency, good stability and firmness, and optimized component weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

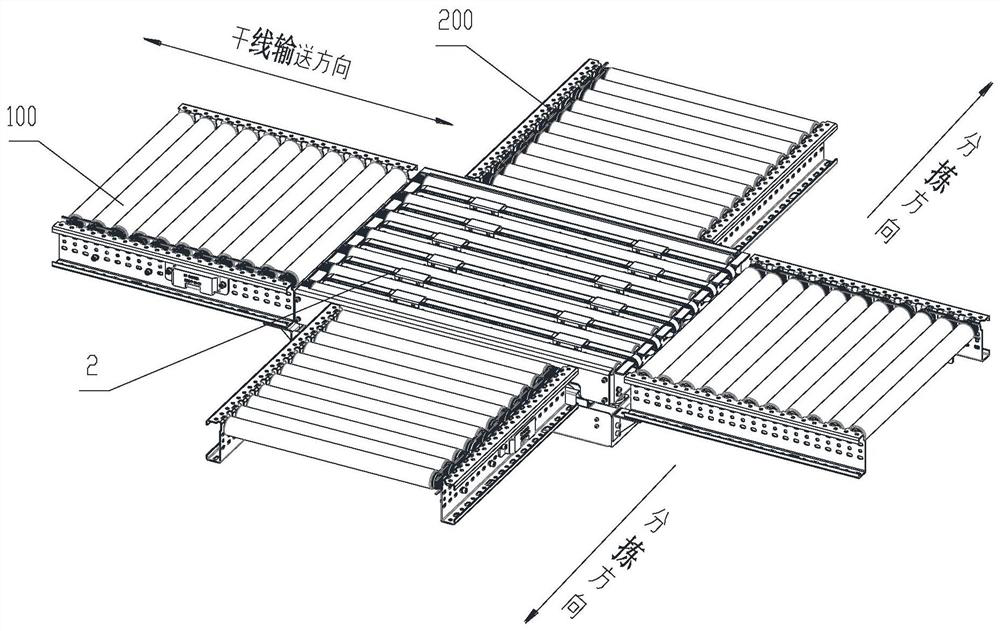

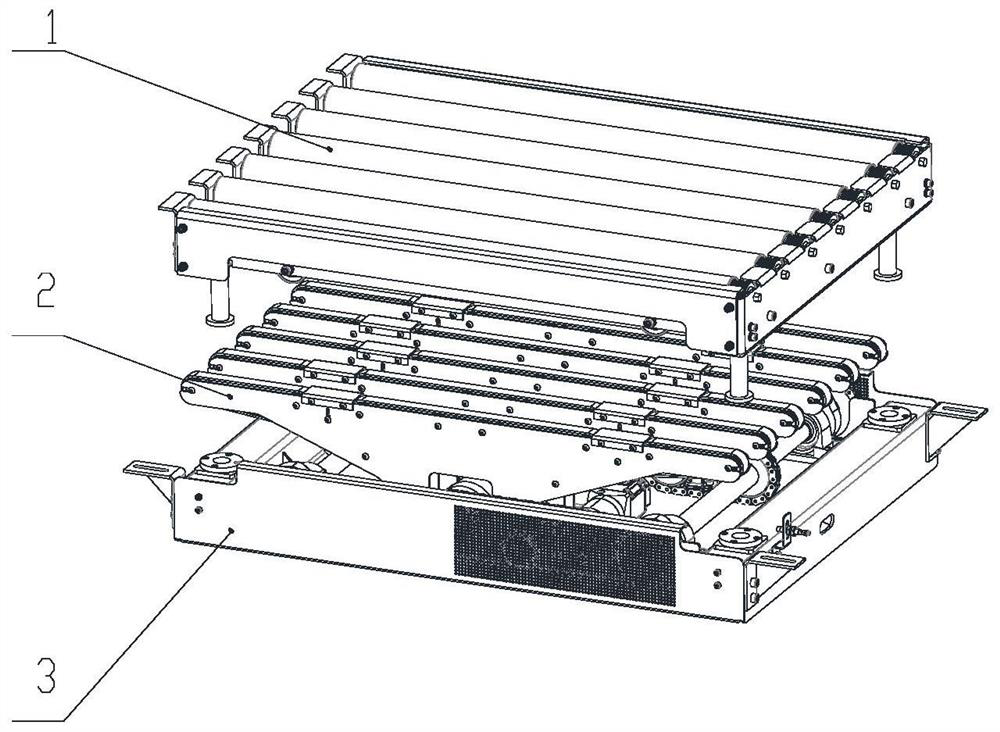

[0035] Embodiment 1, as attached above Figure 1 to Figure 7 As shown, the high-speed jacking and transfer machine described in this application is integrally nested and installed between the trunk conveyor line 100 and the sorting conveyor line 200, which includes vertically stacked and connected jacking components 1 and belt conveyor components. 2 and jacking drive and delivery transmission assembly 3.

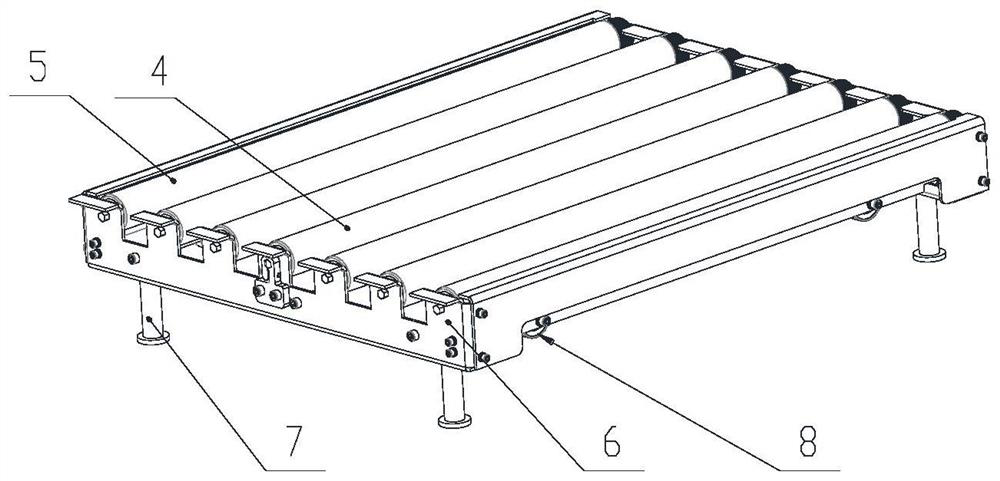

[0036] Wherein, the jacking assembly 1 includes an electric roller 4 and multiple sets of driven rollers 5 installed inside the roller mounting base 6 , and four guide columns 7 and four sets of roller assemblies 8 are connected to the bottom of the roller mounting base 6 . The jacking assembly 1 is driven by the electric drum 4, and synchronously drives multiple groups of driven drums 5 to rotate through the V-belts connected at both ends (not shown in the figure), and the electric drum 4 drives multiple sets of driven drums by rotating clockwise or counterclockwise. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com