Chromium contamination in-situ remediation method

An in-situ repair and chromium pollution technology, which is applied in the field of chromium pollution treatment, achieves the effect of improving utilization rate, simple construction equipment, and conducive to redevelopment and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to facilitate the understanding of the purpose, technical solutions and effects of the present invention, the present invention will now be further described in detail in conjunction with examples.

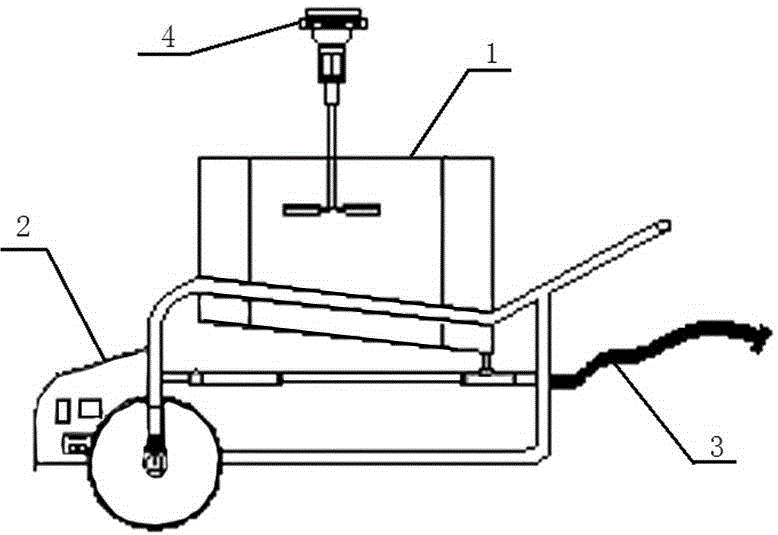

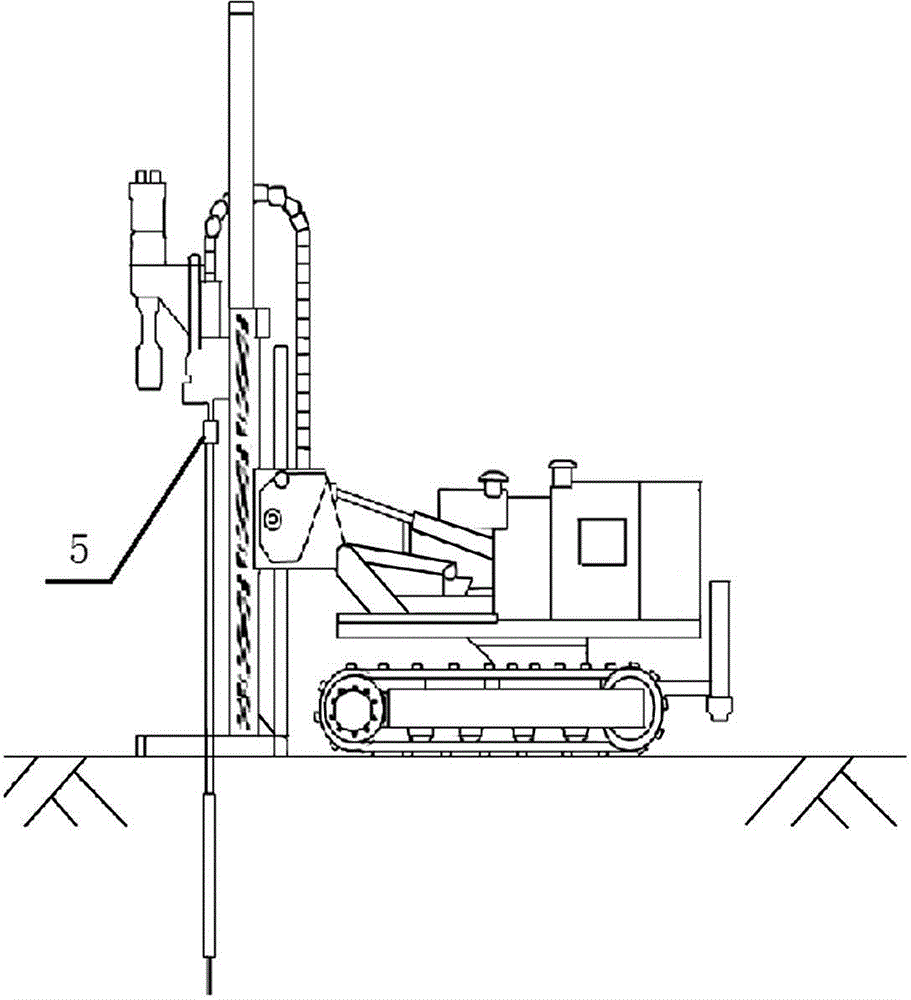

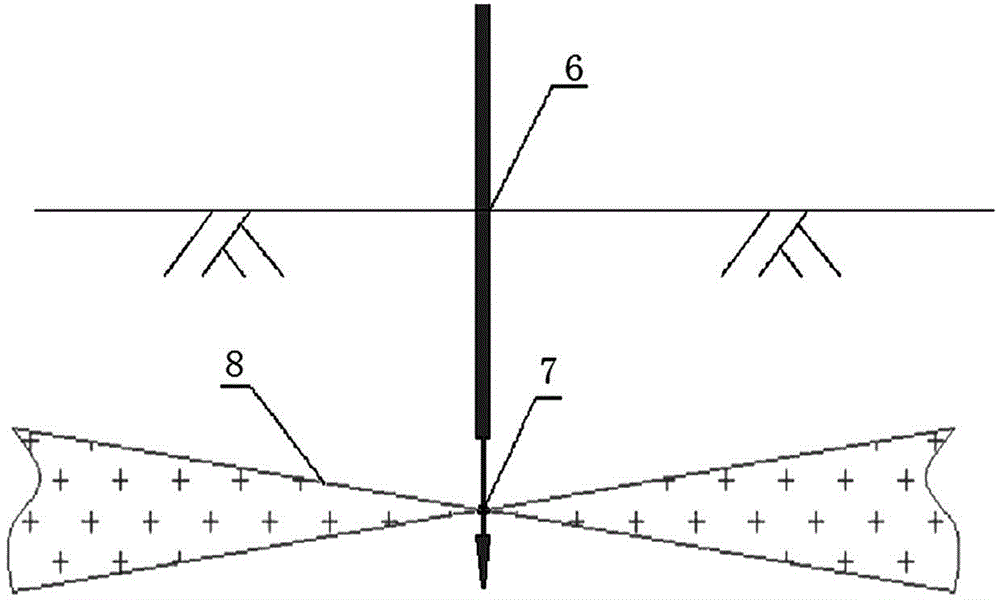

[0054] This embodiment provides a kind of in-situ repair system (hereinafter referred to as in-situ repair system) of chromium pollution, as figure 1 and figure 2 As shown, it includes the chemical mixing and injection system and the drilling system. The drilling system cooperates with the chemical mixing and injection system to directly inject the repairing agent into the site to be repaired through high-pressure equipment (grouting pump 2 of the chemical mixing and injection system) That is, in the saturated layer, the repair agent migrates and diffuses, contacts and reacts with Cr(VI), reduces and stabilizes Cr(VI), eliminates its health risks, and achieves the purpose of repair. The saturated layer is a saturated aquifer soil or a groundwater polluted area. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com