Concrete T-shaped beam post-fire damage evaluation method

A concrete and fire technology, applied in the field of grade evaluation, can solve problems such as reverse order, difficulty in obtaining good evaluation results, and the complexity of determining indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

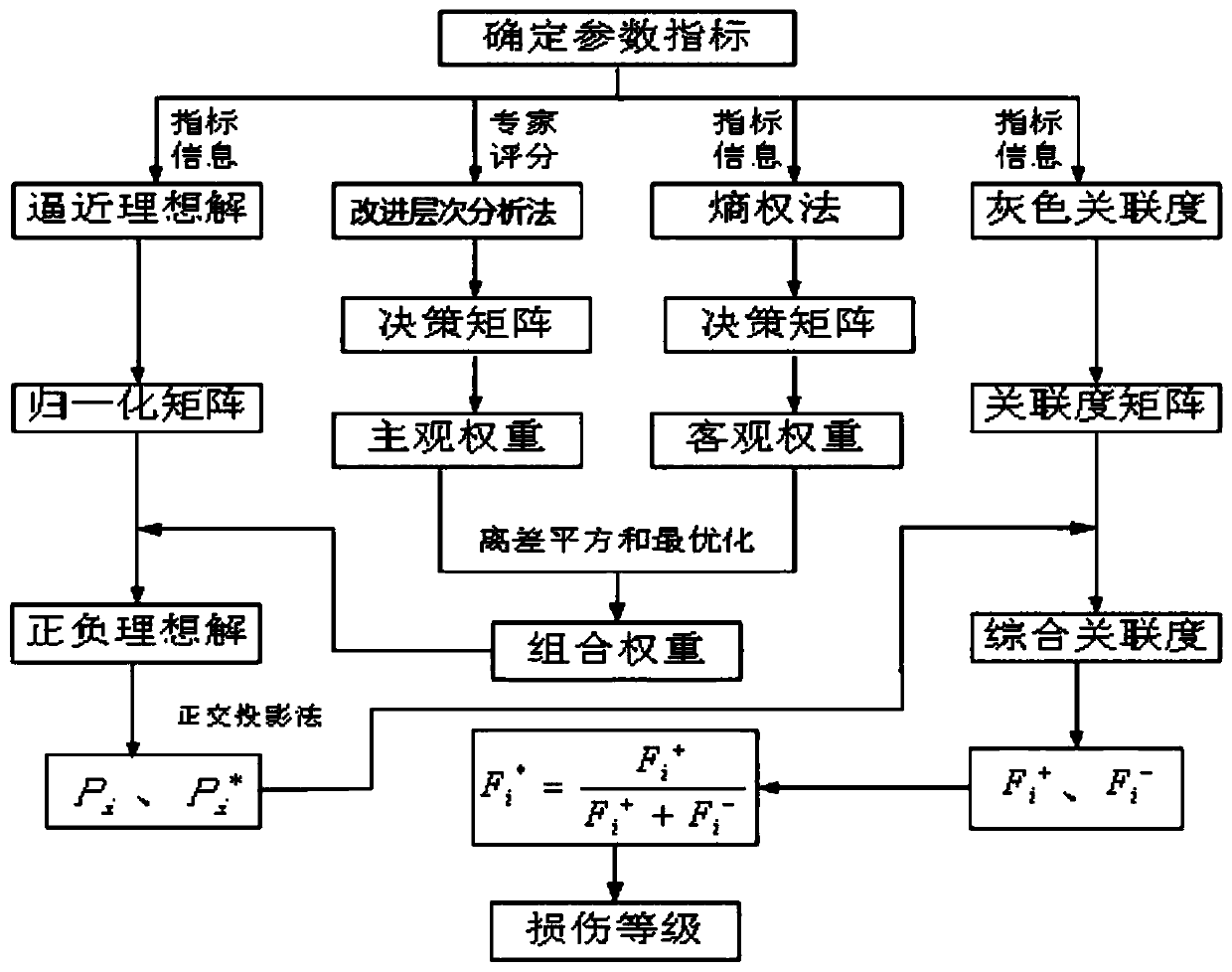

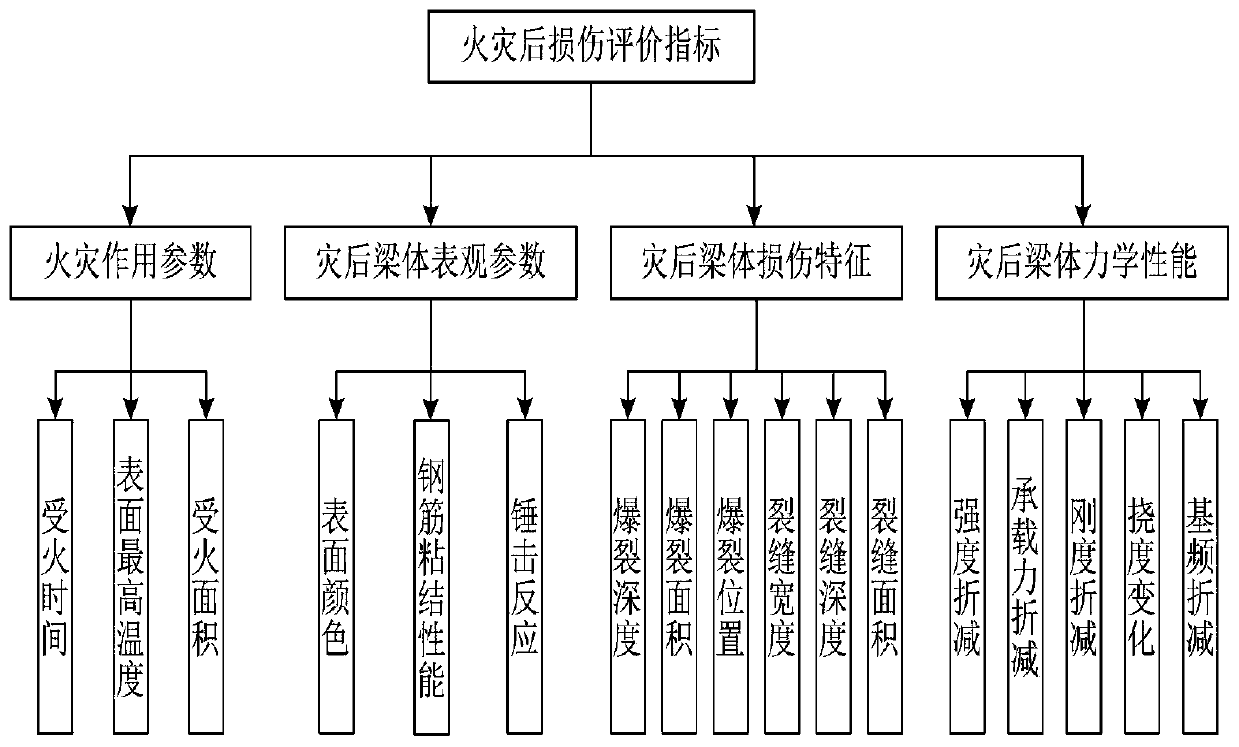

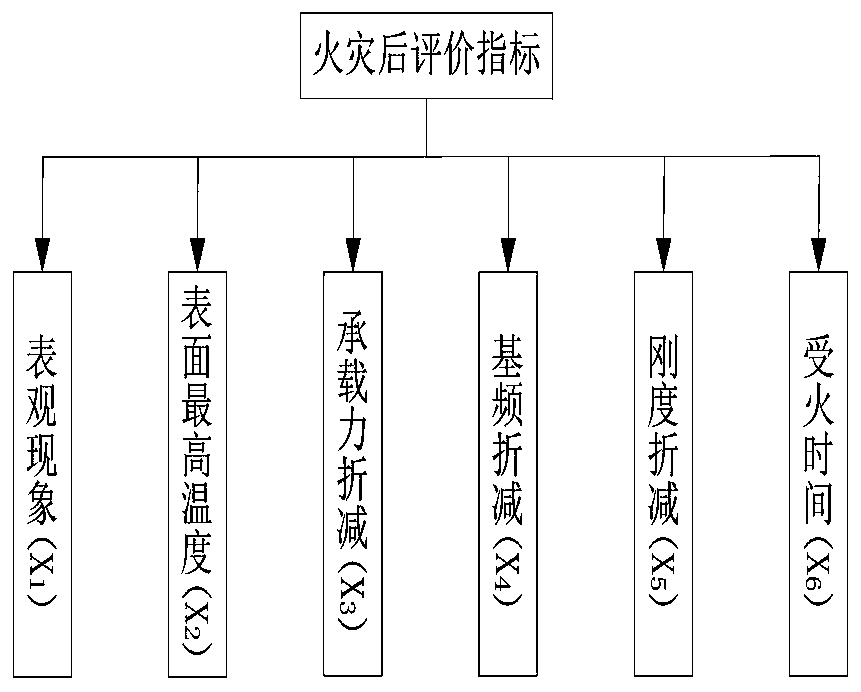

Method used

Image

Examples

experiment example

[0240] The length of 10 T-shaped beams is 3000mm, the clear span is 2800mm, the cross-section and reinforcement are exactly the same, the thickness of the protective layer is 30mm, one comparative beam is only subjected to static load test, and the other 9 T-shaped beams are subjected to different working conditions The cross-load heating test, the test groups are shown in the following table:

[0241] Test grouping situation

[0242]

[0243] Note: Explanation of B-T06L0: B stands for beam, T06 stands for 60min after fire, L0 stands for load ratio is 0; N stands for natural state;

[0244] It means the cracking load, so that the beam is in an uncracked state before the high temperature; the common load is dead load + 0.4 live load, 0.4 is the common coefficient, which represents the load under normal use.

[0245] Damage assessment of B-L0 and B-L12 test beams

[0246] The subjective index weights are based on the improved analytic hierarchy process. The determination of the weights a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com