Shuttle child-mother vehicle for automatically carrying materials in and out from warehouse

A technology for in-out and out-of-warehouse, sub-mother car, applied in the field of automation, can solve the problems of long discharge path of material racks, low handling efficiency, difficult to guarantee handling accuracy and safety factor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

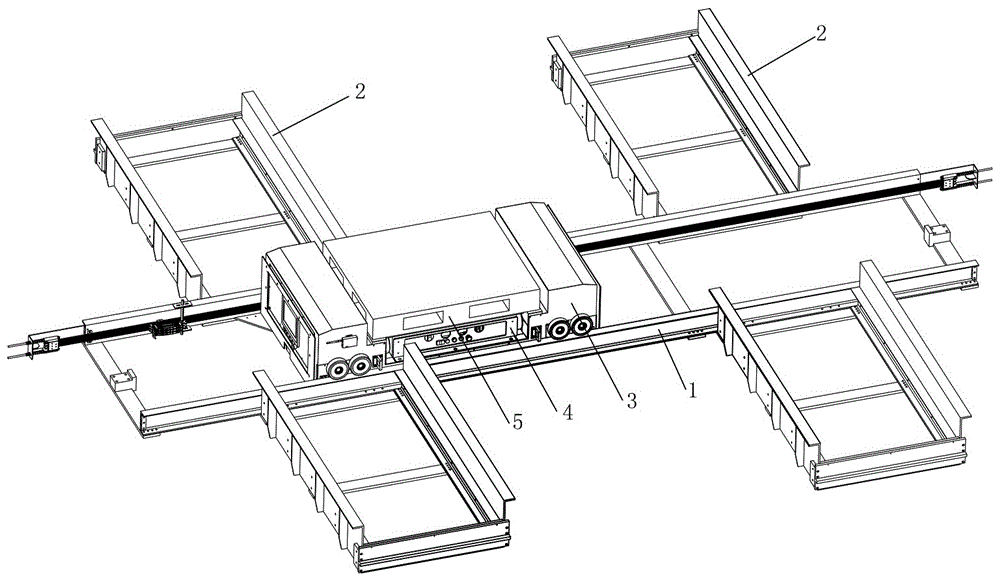

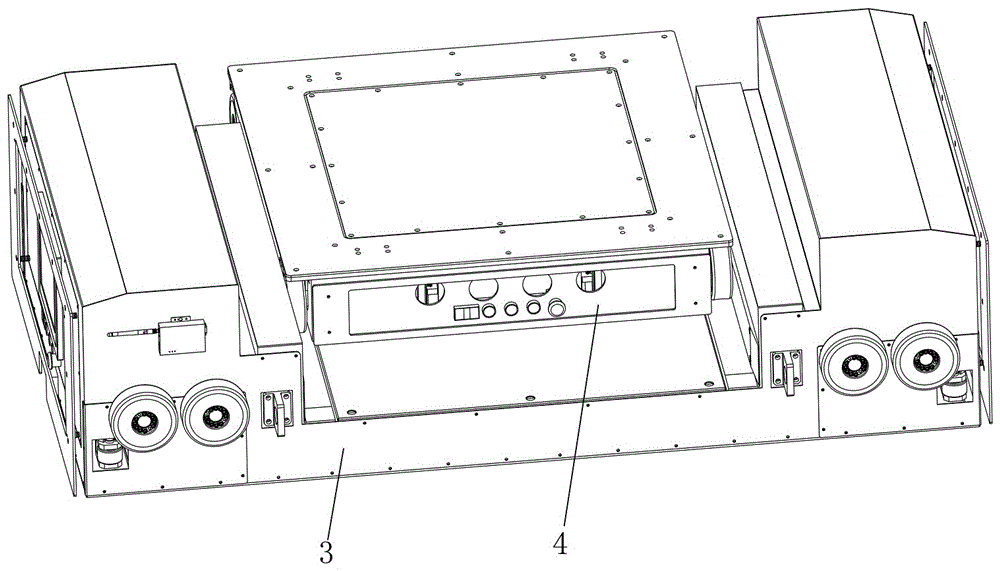

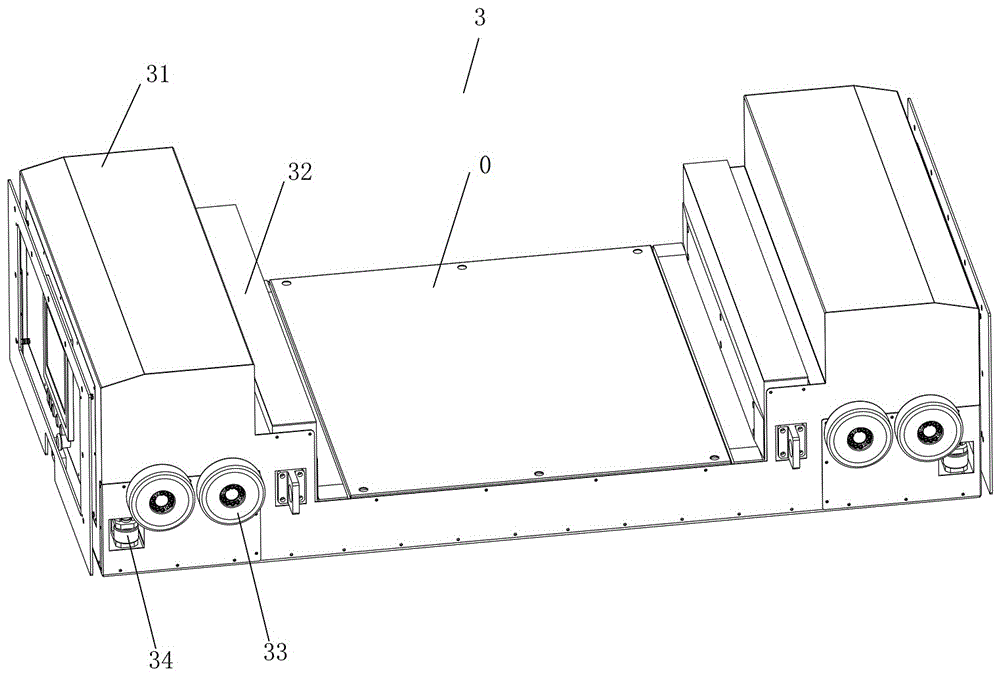

[0034] Such as Figure 1 to Figure 11 As shown, the technical scheme adopted by the present invention is as follows: a kind of shuttle car for the automatic handling of materials in and out of the warehouse, including at least two parallel and spaced roadways 1 and rails 2 vertically connected to the two sides of the roadway 1, the roadway 1 and The track 2 forms a material transportation track, and also includes a mother car 3 and a sub-car 4 slidably arranged on the mother car 3, wherein the above-mentioned mother car 3 is arranged on the above-mentioned roadway 1, and slides linearly back and forth along the roadway 1, and the mother car The middle part of 3 is provided with an inwardly recessed sub-car slot 0, and slideways 32 are respectively provided on both sides of the sub-car slot 0; the above-mentioned sub-car 4 is arranged in the sub-car slot 0, and the sub-wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com