Method for strengthening wood beam

A technology of wood beams and bamboo pieces, applied in the direction of joists, girders, trusses, etc., can solve the problems of destroying the facade and style features of buildings, affecting the integrity and safe use of connected wooden columns, bucket arches and wooden roof trusses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

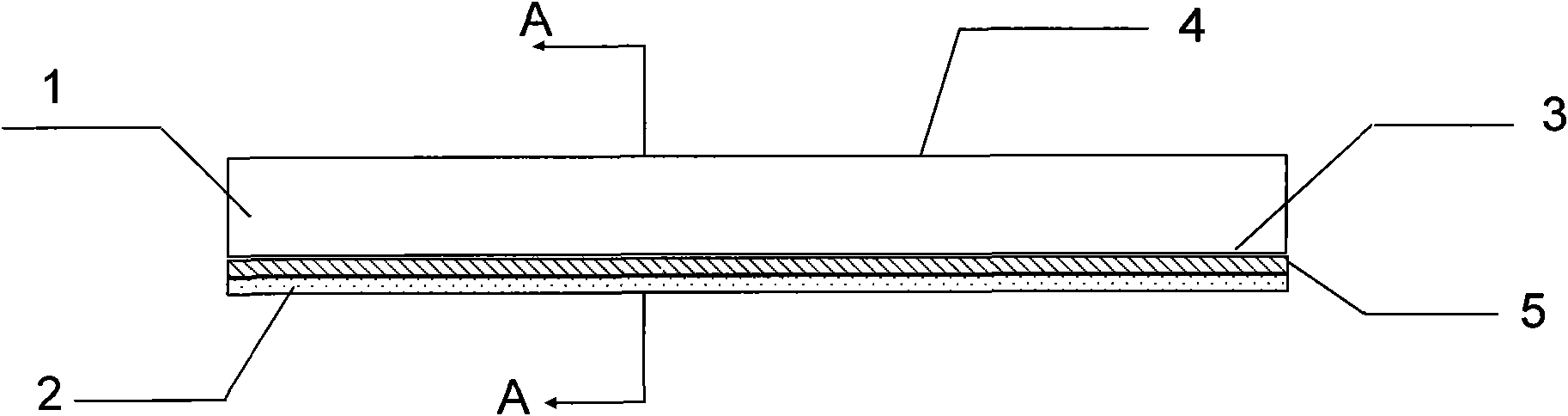

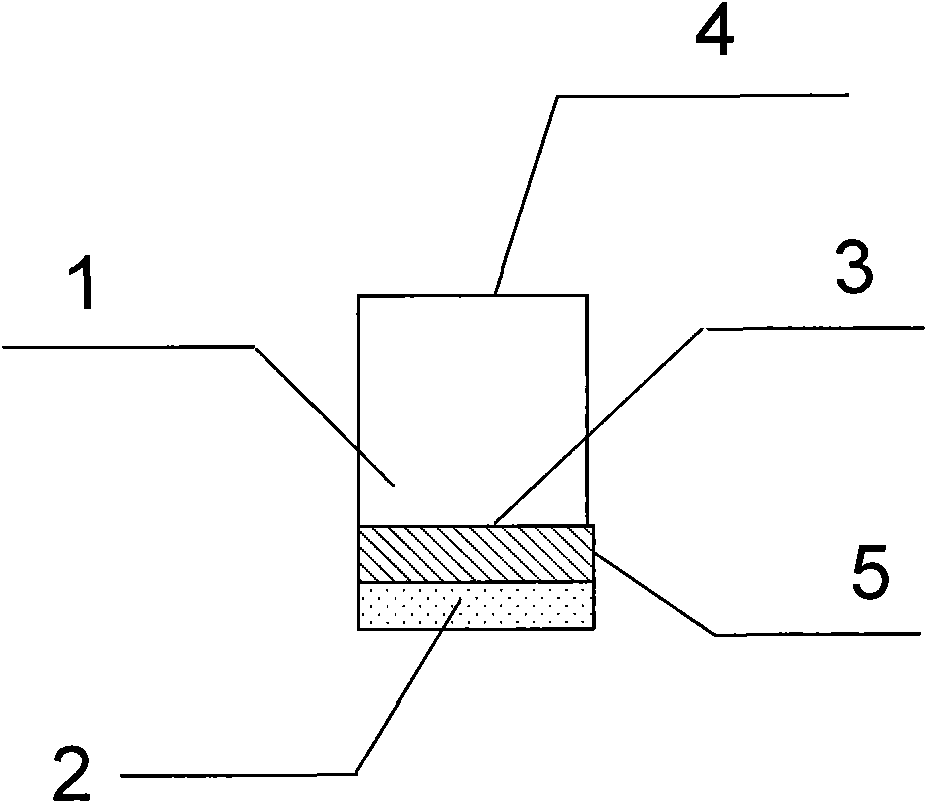

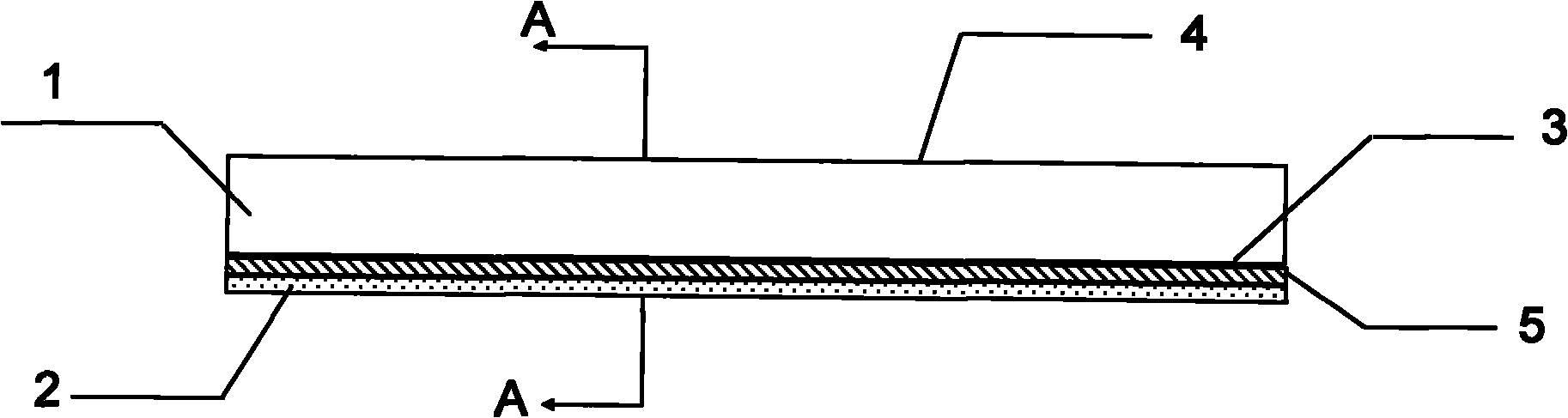

[0017] Due to the increase in load, the bearing capacity of the 200mm wooden beam cannot meet the safety requirements and needs to be reinforced. Such as figure 1 , 2 As shown, the upper part of the wooden beam 1 is the compression surface 4, and the bottom is the tension surface 3. The implementation steps are:

[0018] (1) Unload the load on the wooden beam first. Surface smoothness treatment is carried out on the tensile surface 3 (ie bottom surface) of the wooden beam 1, and scrubbed with acetone, so that the flatness and cleanliness of the tensile surface (bottom surface) meet the paste requirements. If there are cracks or pits on the bottom surface, it needs to be repaired with repair glue.

[0019] (2) Select processed bamboo chips 2 with a thickness of 5 mm, a width of 18 mm, and the same length as the wooden beam, and scrub them with acetone.

[0020] Apply primer on the tensioned surface of the wooden beam, and then stick the bamboo slice 2 on the tensioned surf...

Embodiment 2

[0024] Due to aging, the bearing capacity of the wooden beam with a height of 120mm cannot meet the safety requirements and needs to be reinforced. Such as figure 1 , 2 As shown, the upper part of the wooden beam 1 is the compression surface 4, and the bottom is the tension surface 3.

[0025] The implementation steps are:

[0026] (1) Unload the load on the wooden beam first. Surface smoothness treatment is carried out on the tensile surface 3 (ie bottom surface) of the wooden beam 1, and scrubbed with acetone, so that the flatness and cleanliness of the tensile surface (bottom surface) meet the paste requirements. If there are cracks or pits on the bottom surface, it needs to be repaired with repair glue.

[0027] (2) Select processed bamboo chips 2 with a thickness of 5 mm, a width of 15 mm, and the same length as the wooden beam, and scrub with acetone.

[0028] Apply primer on the tensioned surface of the wooden beam, and then stick the bamboo slice 2 on the tensione...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com