Novel steel truss concrete slab form support system

A technology of floor formwork and support system, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc. It can solve the problems of affecting decoration, electromechanical installation, affecting the construction period, and high cost. The effect of shortening the construction period, saving the cost of construction measures, and reducing the input of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

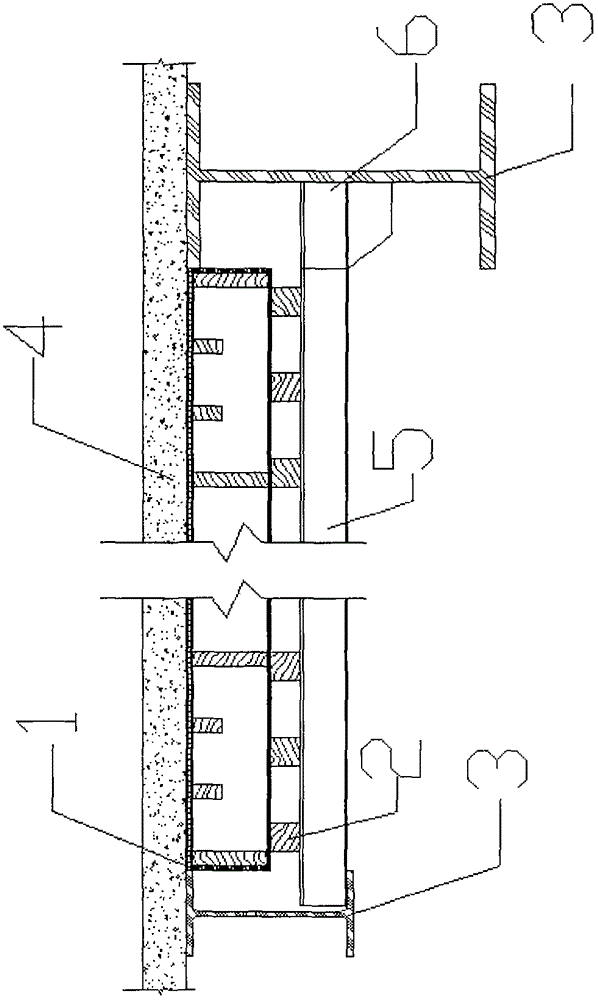

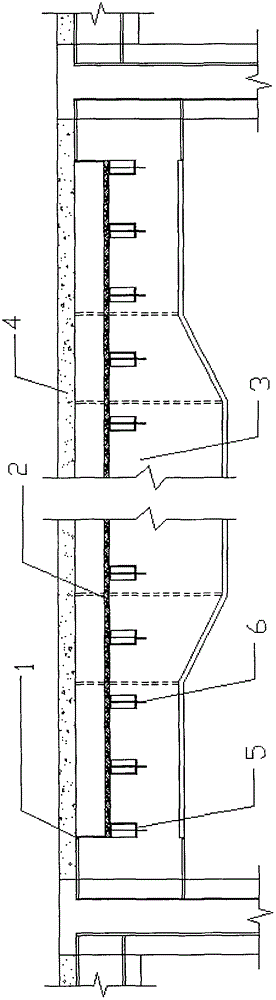

[0015] Attached below Figure 1-2 The present invention is illustrated by way of example, but the specific embodiments are not intended to limit the present invention.

[0016] The new steel truss concrete floor formwork support system as shown in the figure includes steel truss beams 3, I-shaped steel keels 5, forming formwork boxes 1, square wooden beams 2, steel plate welding corbels 6, and concrete floors 4 to be poured. The I-shaped steel keel 5 is arranged between the steel truss beams 3 and used as the main load-bearing member of the supporting formwork, and the square wooden frame 2 is distributed vertically to the I-shaped steel keel 5 and a forming template box 1 is arranged on its upper part. The forming formwork box is used as the bottom mold of the concrete floor 4, and the steel plate welding corbel 6 is welded on the steel truss steel beam 3 as the support of the I-beam.

[0017] The specific implementation is as follows:

[0018] Weld the steel plate welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com