Steel-structure-polyurethane-material underground pipe gallery or working well

A technology of polyurethane materials and underground pipe corridors, which is applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problems of inconvenient cable replacement, personal casualties, etc., and achieve shortened construction period, long service life, insulation good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

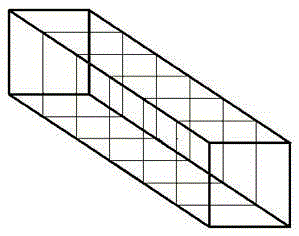

Image

Examples

preparation example Construction

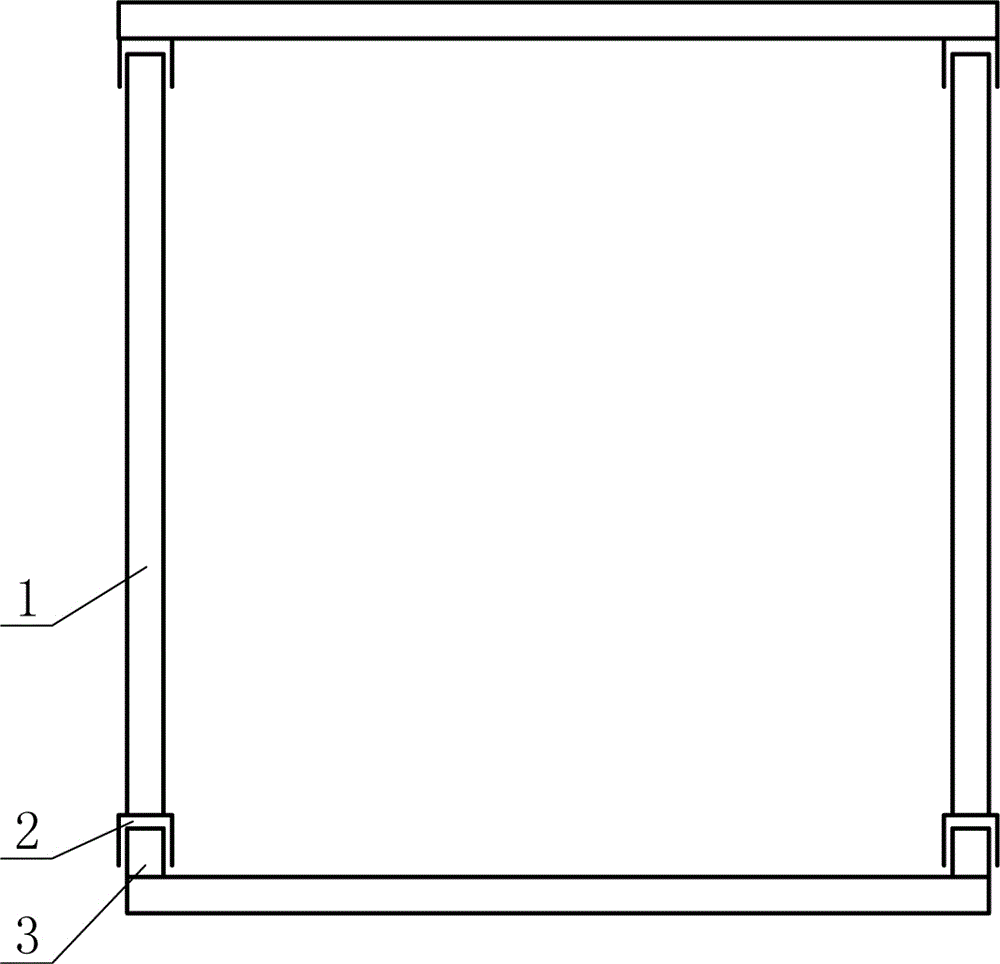

[0031] The preparation method of the wall board is: use a thermosetting polyurethane board as the middle layer, respectively use glass fiber cloth as the outer layer, and use a cement board as the inner layer. The glass fiber cloth and the cement board are compositely fixed on the outer large surface and the inner large surface of the thermosetting polyurethane board respectively.

[0032] An embodiment of a pipe gallery unit structure of the present invention figure 2 , the lower side of the longitudinal steel structure polyurethane wall panel 1 has an insertion groove 2; There are insertion grooves 2 respectively, and the means of the longitudinal steel structure polyurethane wallboard 1 is inserted into the insertion groove 2, and the insertion groove 2 at the lower end is matched with the insertion convex falcon 3. There is sealant in the insertion groove 2 .

preparation Embodiment 1

[0034] 17 parts of toluene diisocyanate, 100 parts of polyadipate diisocyanate, 10 parts of 3,3'-dichloro-4,4'-diaminodiphenylmethane (Moka), glass fiber (length 1-1.5mm ) 2 parts, defoamer 2 parts, stir evenly, and solidify at 100 ℃ to make a plate.

preparation Embodiment 2

[0036] 15 parts by mass of toluene diisocyanate, 110 parts by mass of polyadipate diisocyanate, 8 parts by mass of 3,3'-dichloro-4,4'-diaminodiphenylmethane, 3 parts by mass of glass fiber and 1 part by mass of defoamer are mixed together, stirred evenly, cured at 105°C, and made into a plate;

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com