Deep water offshore wind power bucket foundation mounting device and method

A technology of installation device and cylindrical foundation, which is applied in the field of installation device for deep-water offshore wind power cylindrical foundation, can solve problems such as hidden risks, high center of gravity, large wind and waves, etc., and achieve the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further elaborated below according to specific embodiments.

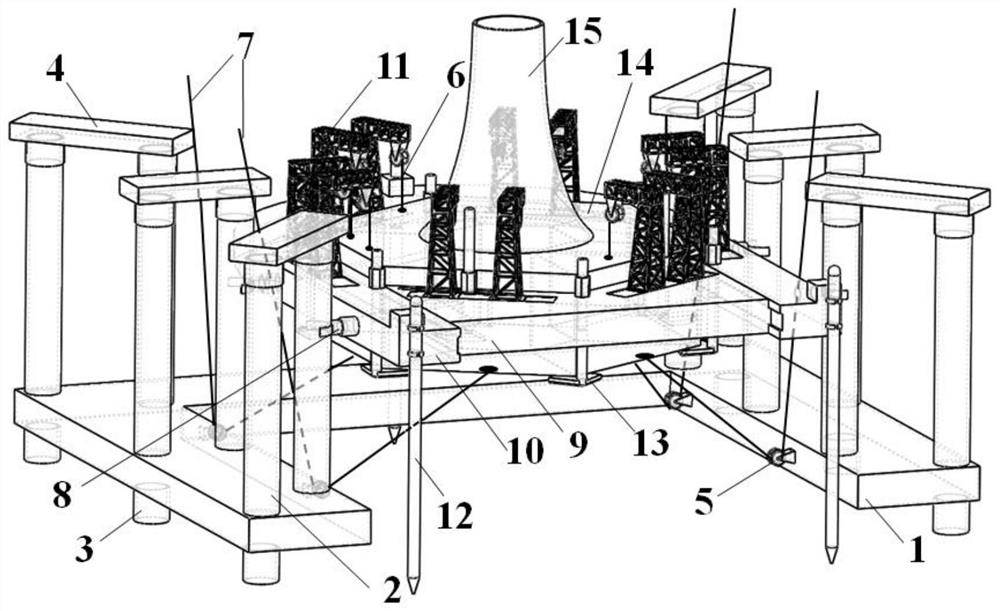

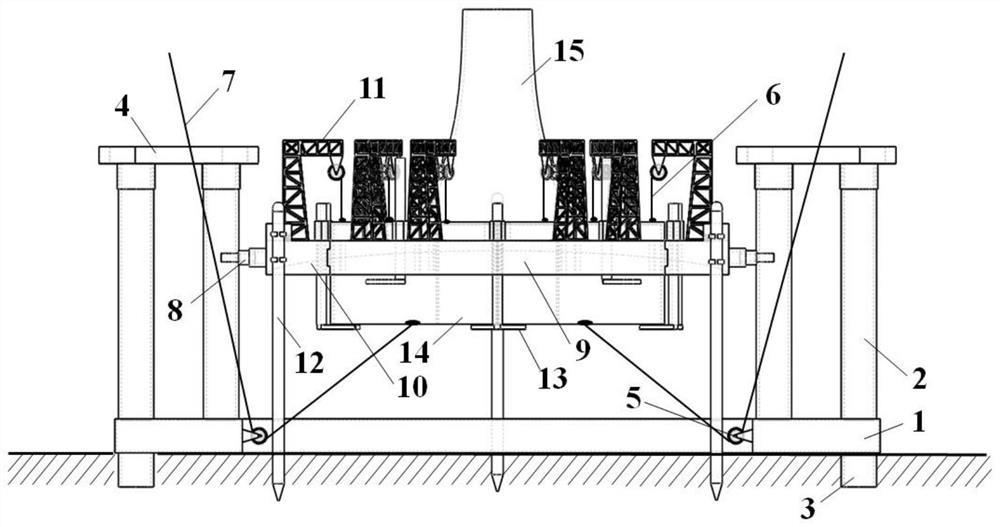

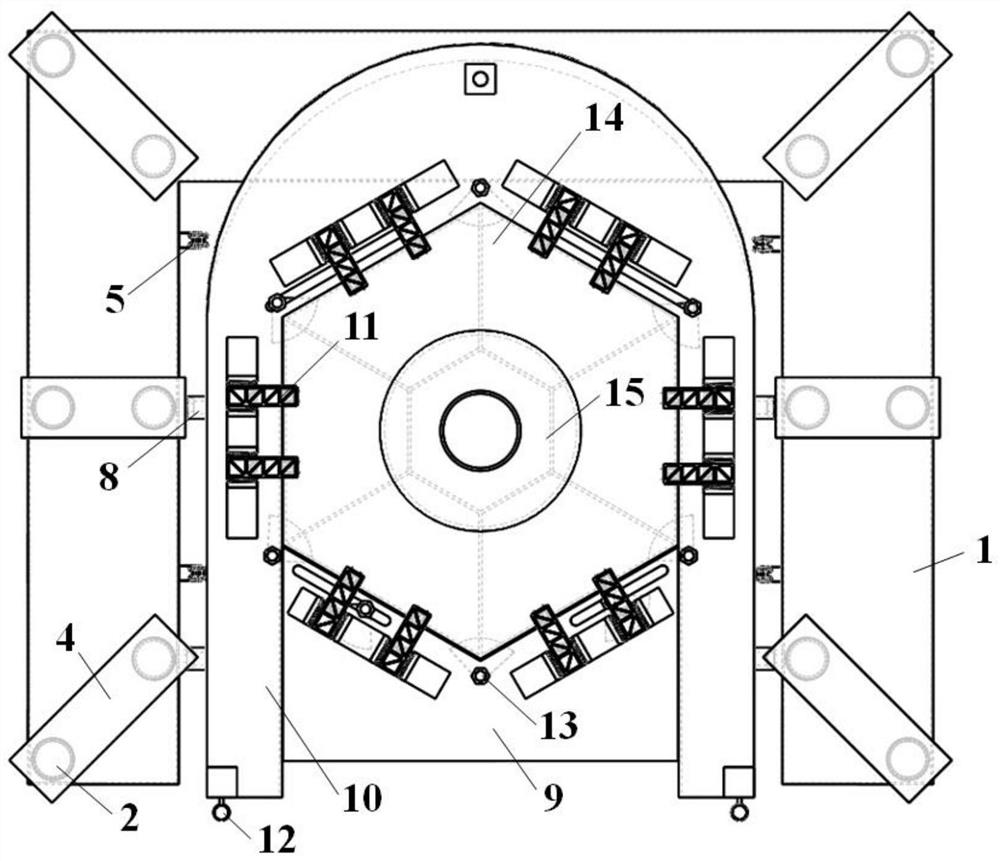

[0035] like Figure 1-6 The deep-water offshore wind power cylinder-type foundation installation device shown includes a sinking pad 1, a floating main body and a cable assembly. The lower surface of the sinking pad 1 is provided with a slot 3, and the upper surface of the sinking pad 1 is provided with a column 2. Top beam 4 is arranged on the top. Every two upright columns 2 form a group, and a top beam 4 is arranged on the top of each group of upright columns 2 . The shape of sinking pad 1 is "U". The sinking pad 1 is a hollow steel box structure. There are air holes on the sinking pad 1. The air pump can inflate the sinking pad 1 through the air holes. The water pump can inflate the sinking pad 1 through the air holes. The pad 1 drains water and is used to deflate the sinking pad 1 before sinking and inflate the sinking pad 1 before floating. The inner wall of the sinking p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com