Construction method for shaft type underground garage

A construction method and parking garage technology, applied in the excavation and construction field of shaft-type underground parking garages, can solve the problems of inapplicability to complex stratum conditions, large investment, and increased construction costs of underground parking garages, and achieve increased anti-floating stability, Good durability, reliable construction method and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

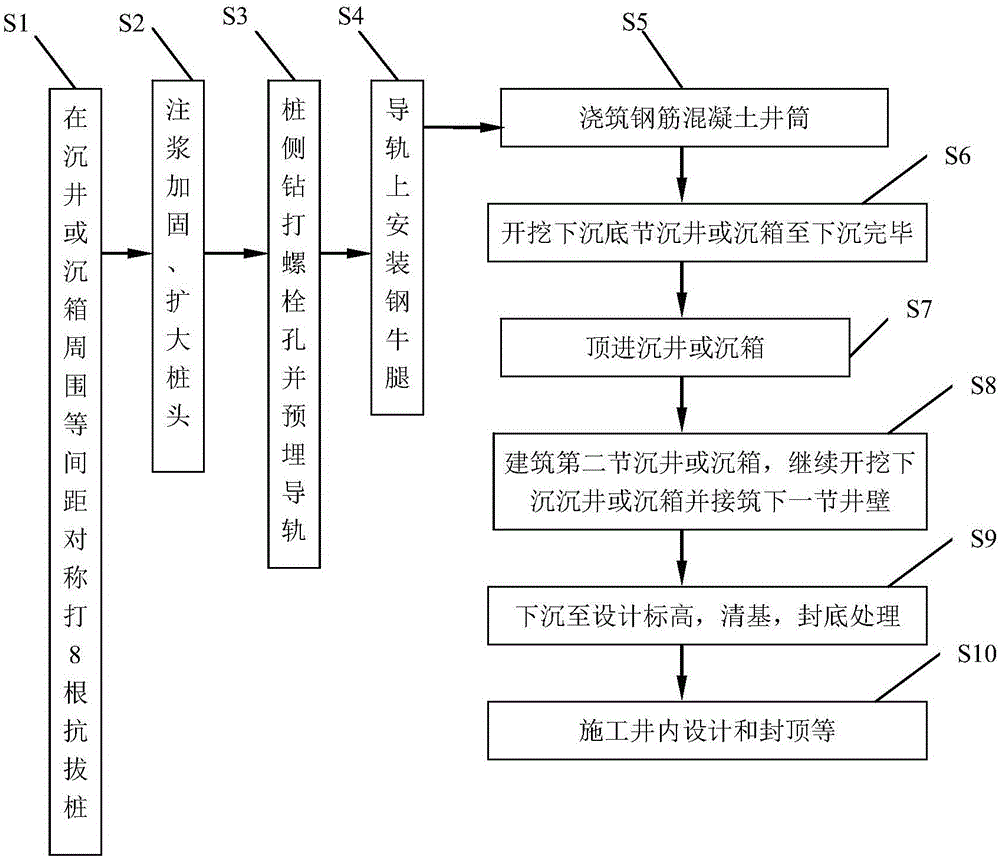

[0039] Such as figure 1 Shown, the construction method of shaft type underground parking garage of the present invention comprises:

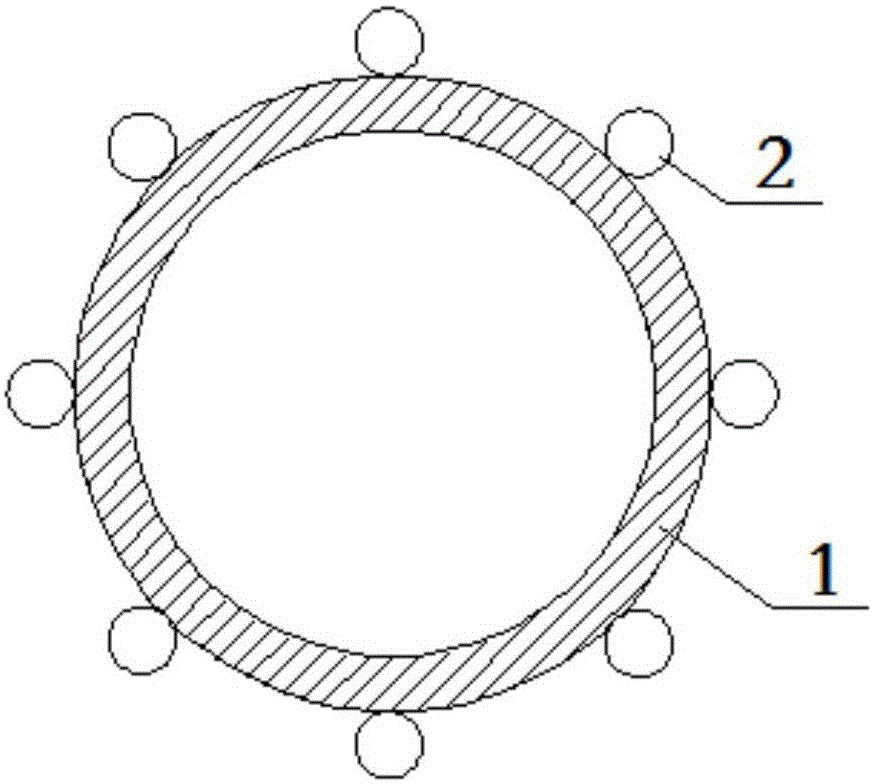

[0040] Step S1: if figure 2 As shown, eight uplift piles 2 are symmetrically drilled at equal intervals around the caisson or caisson 1, and flared uplift piles can be used if necessary.

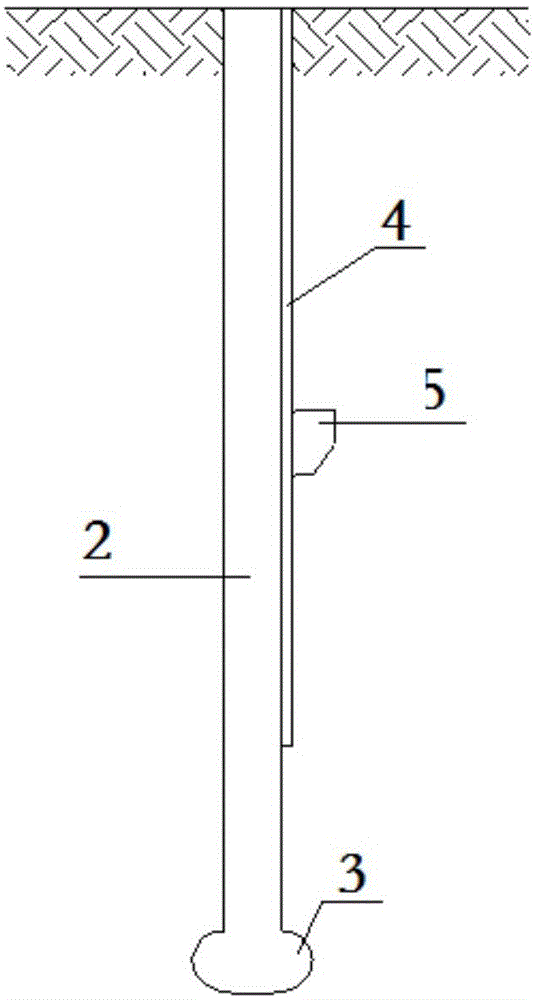

[0041] Step S2: if image 3 As shown, after grouting, the uplift pile 2 is reinforced, and the pile head 3 is enlarged.

[0042] Step S3: if image 3 As shown, bolt holes are drilled on the side of the uplift pile 2 and the guide rail 4 is pre-embedded.

[0043...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com