Treatment method for hanging sinking stop due to expansive soil in well sinking

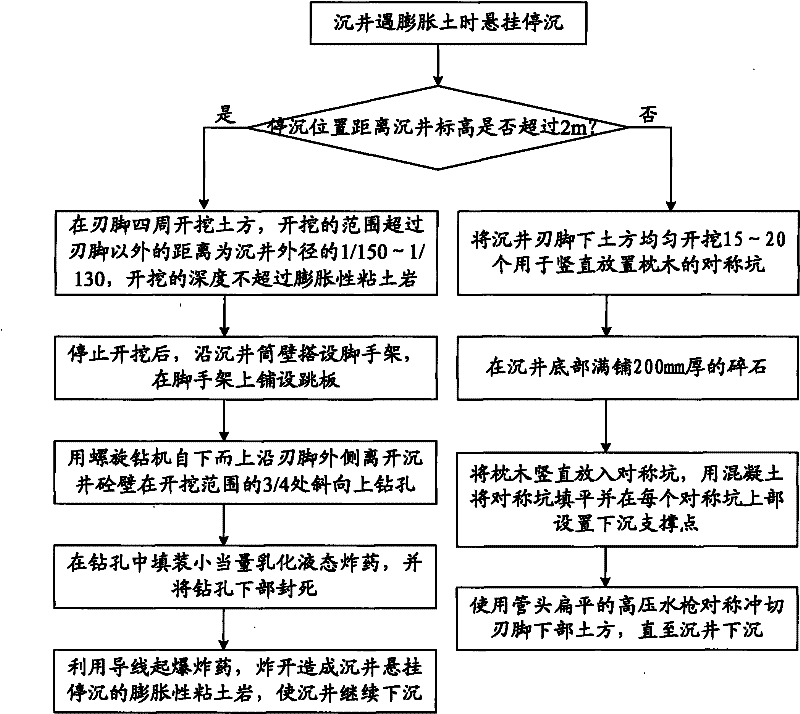

A treatment method and expansive soil technology, which is applied to caissons, blasting, construction, etc., can solve problems such as uneven stress on the circumference of caissons, easily damaged concrete structures, and deviation of caissons, so as to eliminate abnormal side friction resistance and reduce The contact area and the effect of preventing caisson deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0035] For the convenience of expression, hereinafter, expansive clay rock is also referred to as expansive soil for short.

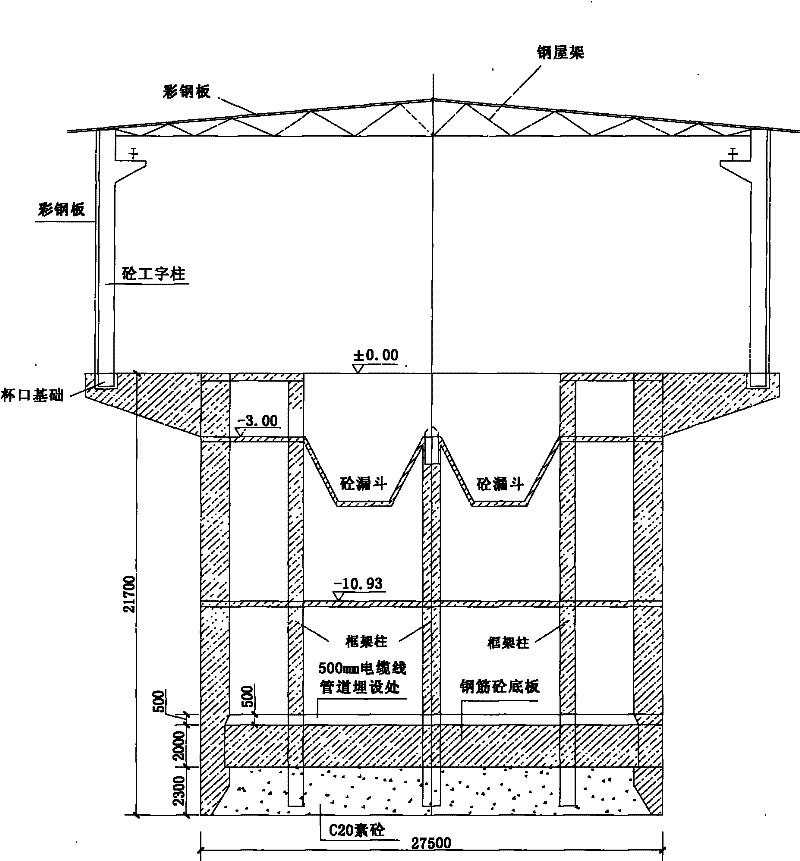

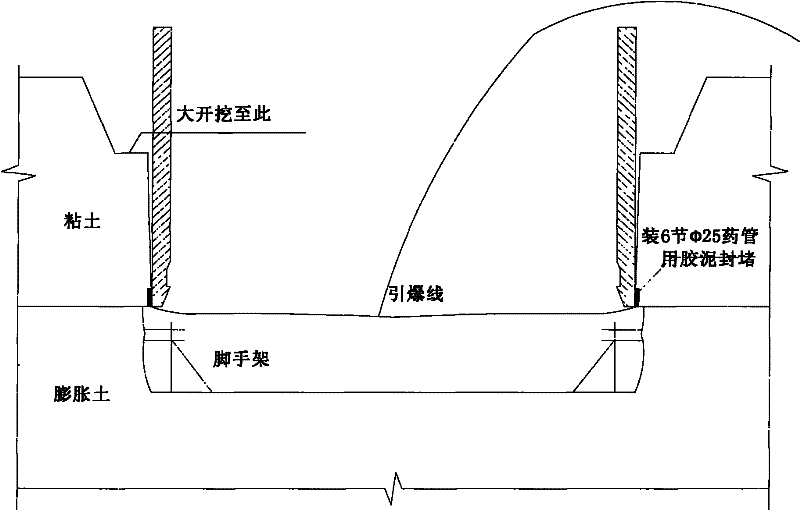

[0036] figure 1 It is a sectional view of a dumper room using a large-scale caisson foundation in an embodiment of the present invention. The present invention takes the excavation of a large-scale caisson as the foundation of a train dumper room in a mechanized raw material factory as an example to describe in detail the treatment method for the suspension and sinking of the caisson when it encounters expansive soil. figure 1 As shown, the circular caisson of the dumper room is 21.7m deep, the outer diameter D is 27.5m, and the wall thickness is 1.5m. The wall of the caisson is made of Φ25200 double-layer two-way steel bars (the edge angle is densified up and down to 150), the width of the edge angle is 600mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com