Semi-cast blast furnace hot blast stove pipe and construction method thereof

A pipeline construction and hot blast stove technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as loosening of upper combined bricks, loose shrinkage of bricks, and damage to hot blast pipes, so as to reduce construction difficulty and material costs, and avoid The generation of weak areas and the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

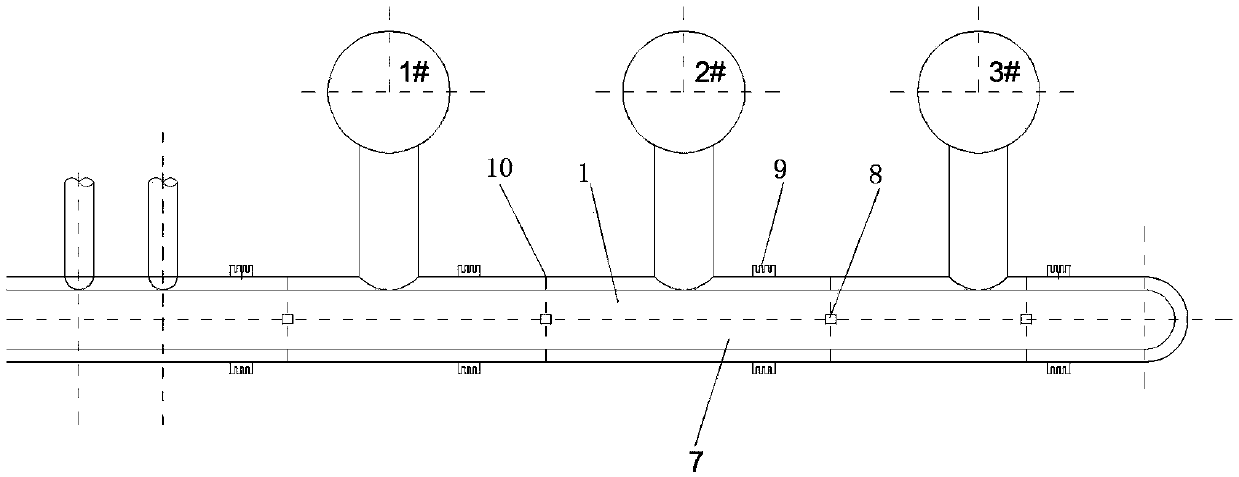

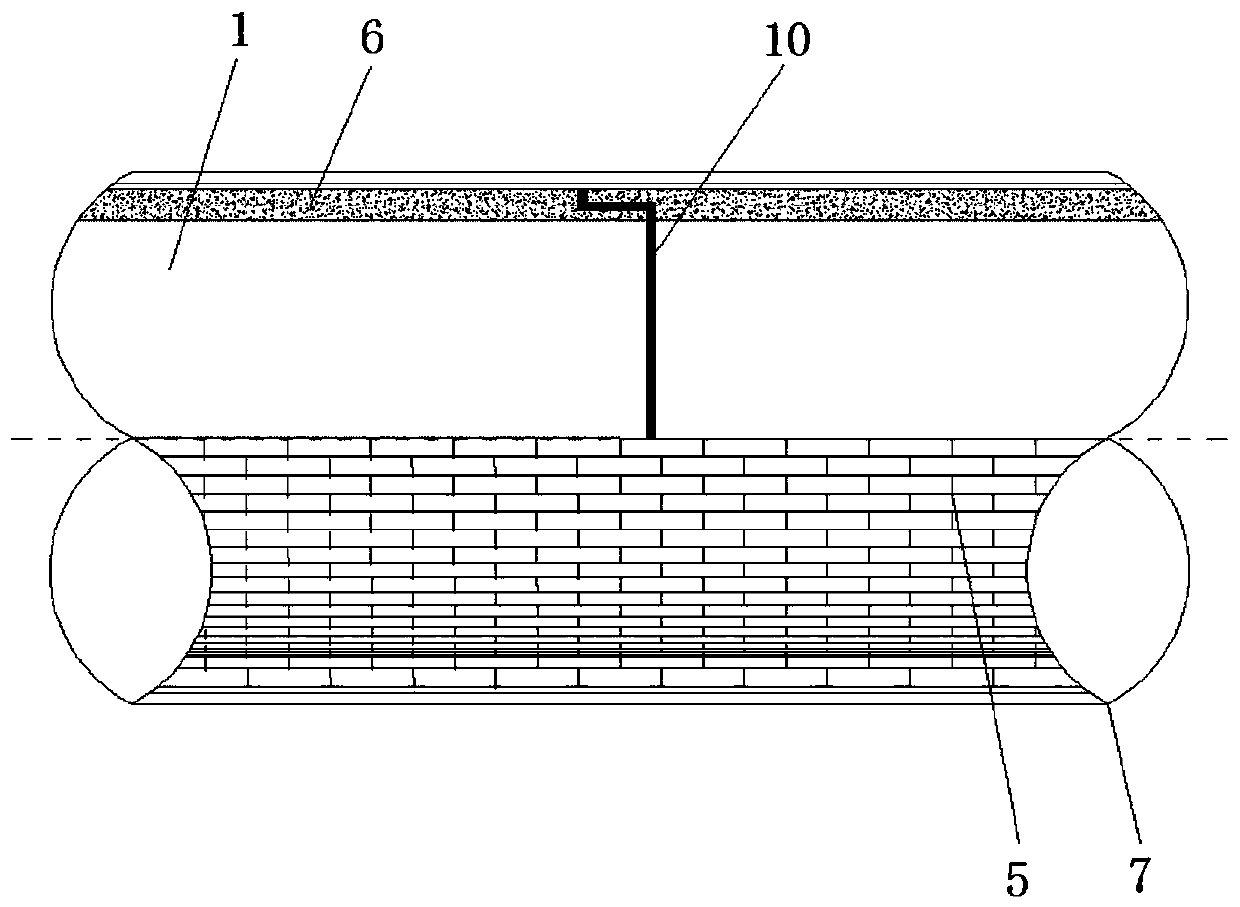

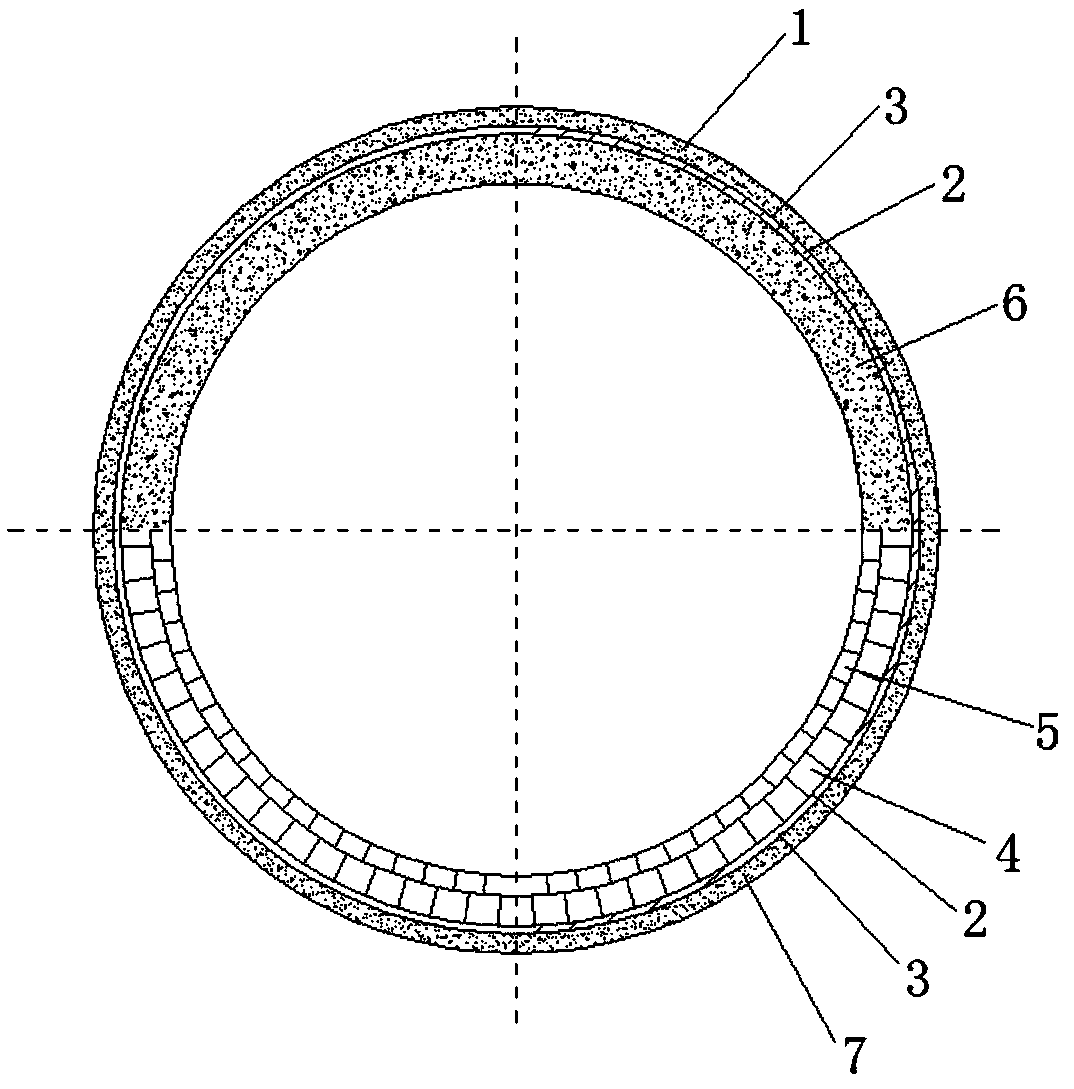

[0034] The hot blast stove pipeline is connected to the hot blast stove, and its configuration is as follows figure 1 shown. Such as figure 2 and image 3 The shown semi-cast blast furnace hot blast stove pipeline includes a steel shell, which is composed of an upper steel shell 1 and a lower steel shell 7 arranged on the upper and lower sides of the horizontal mid-plane; the lower steel shell 7 is paved with The upper steel shell 1 is provided with an integrally poured castable layer 6.

[0035] Preferably, between the castable layer 6 and the inner wall of the upper steel shell 1, a fiber felt layer 2 and a sprayed layer 3 are sequentially arranged along the radially outward direction of the steel shell, that is, the castable layer 6, the fiber felt layer 2 , the sprayed layer 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com