Super-long underwater pile foundation machine-made sand self-compacting concrete and preparation method thereof

A technology for self-compacting concrete and machine-made sand, applied in the field of building materials, can solve the problems of insufficient concrete setting time, slow pile foundation construction, unstable layers and karst caves, etc., and achieve the effect of realizing ultra-long setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

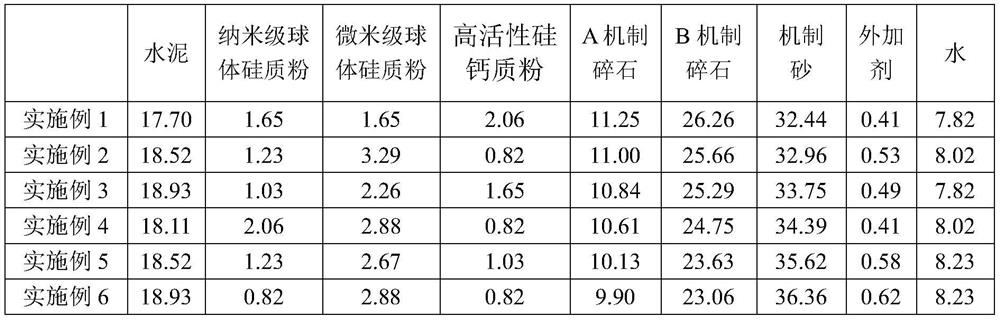

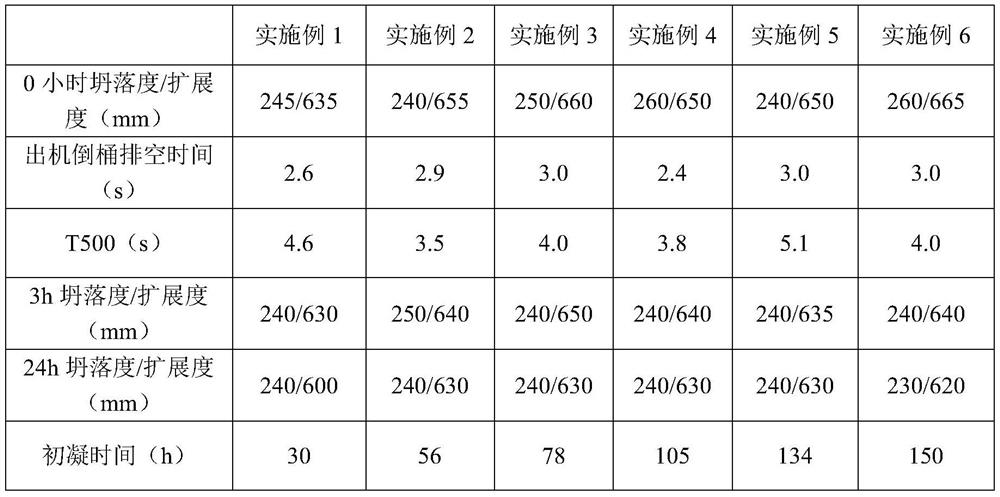

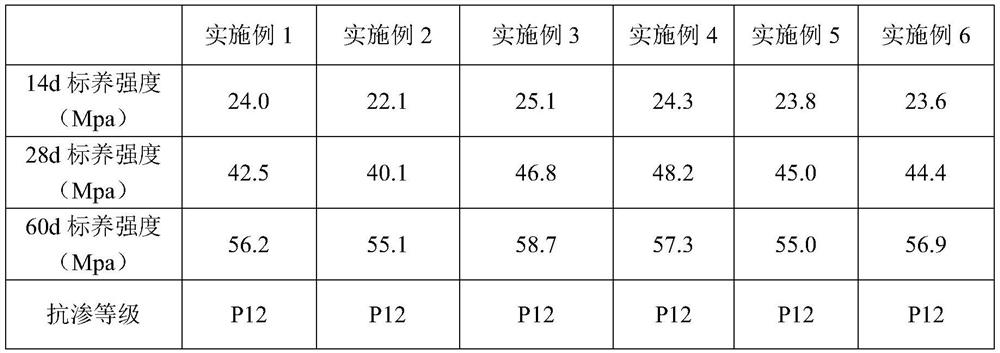

[0020] A method for preparing super-long underwater pile foundation machine-made sand self-compacting concrete, comprising the following steps:

[0021] Step 1: Weigh the cement, nano-scale spherical siliceous powder, micron-scale sphere siliceous powder, high-activity silica-calcium powder, A mechanism crushed stone, B mechanism crushed stone according to the mass ratio of each component in Example 1-6 , machine-made sand, admixture, water;

[0022] Step 2: Fully stir and mix the weighed admixture and water for 5 minutes to obtain a uniform mixture.

[0023] Step 3: Put the weighed cement, nano-sized spheroidal siliceous powder, micron-sized spheroidal siliceous powder, active silica-calcium ore powder, A mechanism crushed stone, B mechanism crushed stone, and mechanism sand in the concrete mixer for 2 minutes to dry mix fully The mixed dry material is mixed, and then the mixed liquid is placed in the mixed dry material and stirred for 2-5 minutes to obtain the ultra-long un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com