Method for isolating solitary stone group on upper portion of shield tunnel through advance pipe shed

A shield tunnel and pipe shed technology, which is applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as the subsidence or subsidence of boulder groups, prevent boulders from squeezing the shield, and reinforce the strata around the pipe shed , Reduce the effect of disturbance range and surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

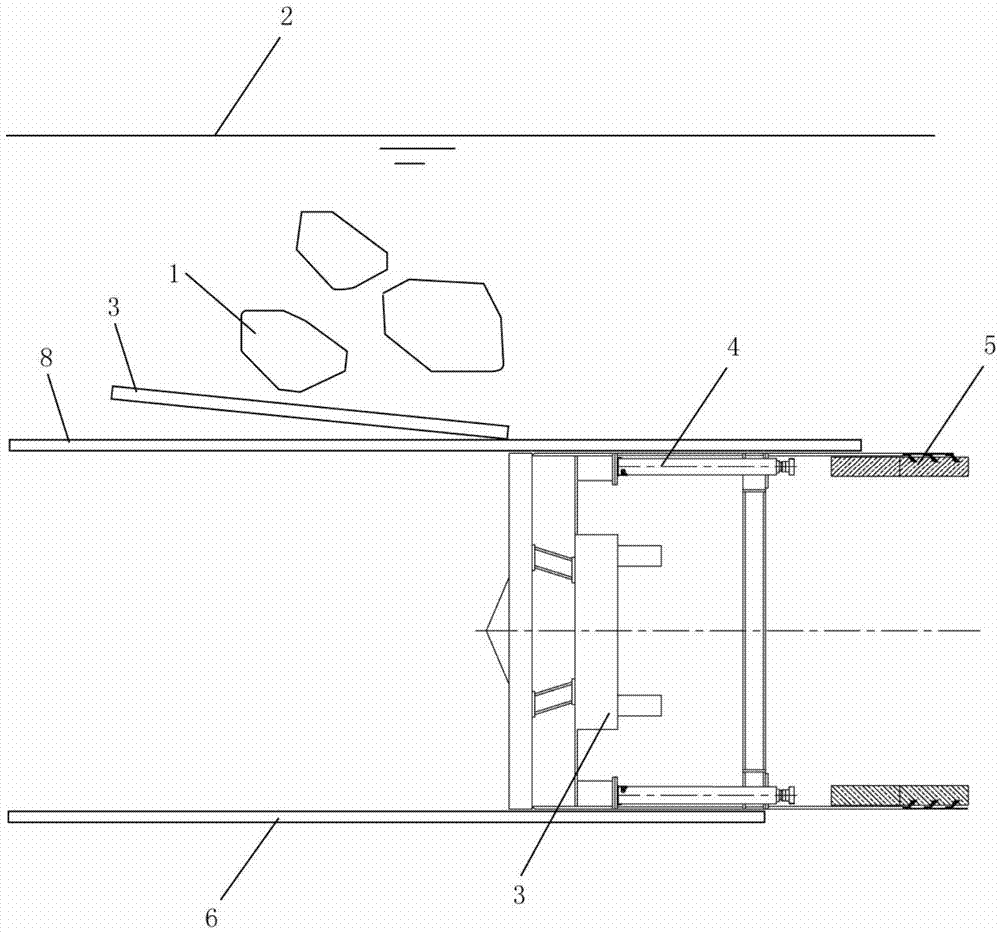

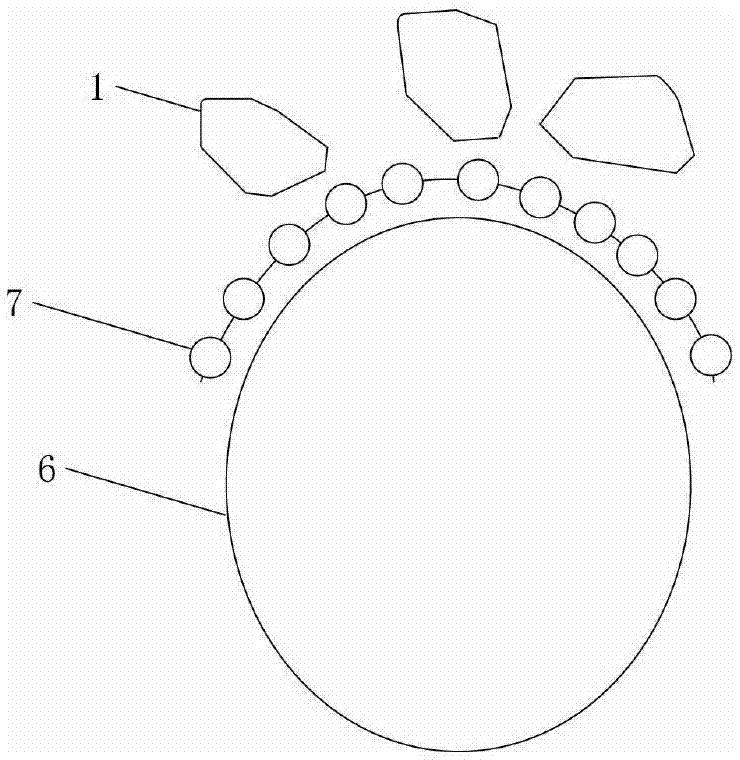

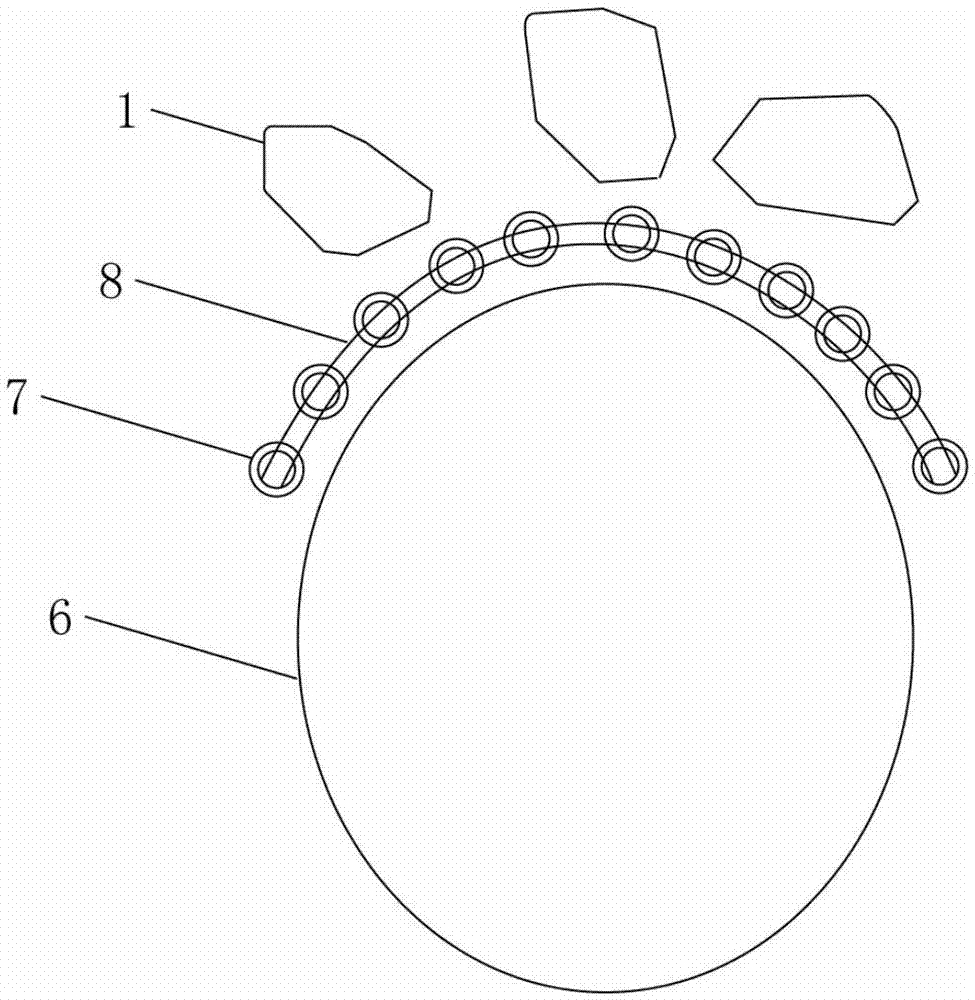

[0032] Such as Figure 1-3 As shown, a method for isolating boulder groups with an advanced pipe shed above a shield tunnel is carried out in accordance with the following steps:

[0033] (1) The shield machine is shut down, and the advanced pipe shed hole 7 is constructed along the top of the tunnel excavation contour line 6 through the cutter head opening. The outer angle of the advanced pipe shed hole 7 does not invade the tunnel excavation contour line 6. The hole depth of 7 is less than or equal to 10m and exceeds 1m in front of the boulder 1. The diameter of the advanced pipe shed hole 7 is 80mm. The spacing is 0.5m, and the drilling sequence of the advanced pipe shed holes 7 is from high hole position to low hole position;

[0034] (2) Use quick-setting high-pressure concrete to inject grout into the advance pipe shed hole 7, and stop grouting until the advance pipe shed hole 7 flows;

[0035] (3) Repeat steps (1) and (2) until all 30° ranges on both sides of the tunn...

Embodiment 2

[0040] Such as Figure 1-3 As shown, a method for isolating boulder groups with an advanced pipe shed above a shield tunnel is carried out in accordance with the following steps:

[0041] (1) The shield machine is shut down, and the advanced pipe shed hole 7 is constructed along the top of the tunnel excavation contour line 6 through the cutter head opening. The outer angle of the advanced pipe shed hole 7 does not invade the tunnel excavation contour line 6. The hole depth of 7 is 5m and exceeds the position in front of the boulder 1 by 1.2m. The diameter of the advanced pipe shed hole 7 is 90mm. The center distance is 0.5m, and the drilling sequence of the advanced pipe shed hole 7 is from high hole position to low hole position;

[0042] (2) Use quick-setting high-pressure concrete to inject grouting into the hole 7 of the advanced pipe shed, and stop grouting until the hole of the advanced pipe shed is fluidized;

[0043] (3) Repeat steps (1) and (2) until all 60° ranges...

Embodiment 3

[0048] Such as Figure 1-3 As shown, a method for isolating boulder groups with an advanced pipe shed above a shield tunnel is carried out in accordance with the following steps:

[0049] (1) The shield machine is shut down, and the advanced pipe shed hole 7 is constructed along the top of the tunnel excavation contour line 6 through the cutter head opening. The outer angle of the advanced pipe shed hole 7 does not invade the tunnel excavation contour line 6. The hole depth of 7 is 10m and exceeds the position in front of the boulder 1 by 1.5m. The diameter of the advanced pipe shed hole 7 is 100mm. The center distance is 0.5m, and the drilling sequence of the advanced pipe shed hole 7 is from high hole position to low hole position;

[0050] (2) Use quick-setting high-pressure concrete to inject grout into the advance pipe shed hole 7, and stop grouting until the advance pipe shed hole 7 flows;

[0051] (3) Repeat steps (1) and (2) until all 60° ranges on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com