Method for supporting deep building pit using non bulit-in end pile anchor in combination with anchor slab wall

A deep foundation pit support and anchor plate wall technology, applied in sheet pile wall, excavation, foundation structure engineering and other directions, can solve the problems of shallow burial depth, long construction period, multiplied cost, etc., so as to shorten the construction period and save money. Significant cost and duration benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

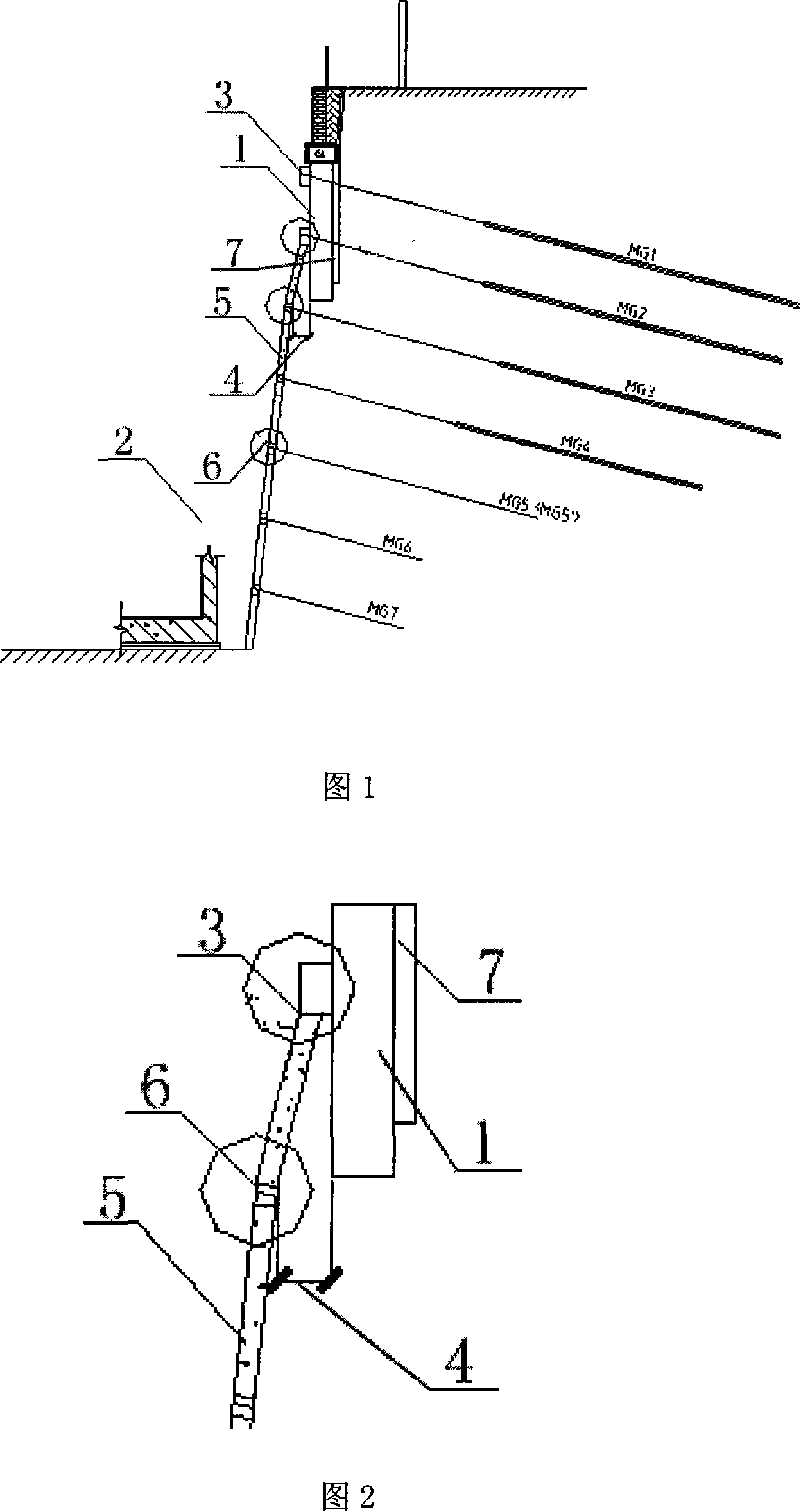

[0013] Please refer to the attached drawing of the manual, a deep foundation pit support method using non-embedded end pile anchors combined with anchor plate walls. The depth of the support pile 1 only enters the pressure zone of the strong weathered rock, and the support piles are poured with long auger drill holes. Concrete technology construction; high-pressure jet grouting piles 7 are set between the support piles 1; foundation pit 2 is excavated, and prestressed anchor rods 3 are respectively installed at the upper, middle, and lower ends of the support piles along with the excavation of the foundation pit; A rock step 4 of 0.5-1.0 m is reserved at the lower end; the side of the foundation pit below the rock step 4 is shotcrete retaining wall 5, and a prestressed anchor rod 6 is set on the concrete retaining wall to form a supporting anchor plate wall.

[0014] Specific steps are as follows:

[0015] 1. Construction of support piles (long auger drilling concrete process)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com