Prestressing force concrete pipe pile for low-temperature geothermal energy conversion

A concrete pipe pile and prestressing technology, applied in the field of multifunctional prestressed concrete pipe piles, can solve the problems of unfavorable traditional bearing performance of pile foundations, complicated construction of coil heat exchangers, extrusion damage of tubular heat exchangers, etc. The effect of avoiding groundwater resource usage fees, eliminating groundwater pollution problems, and increasing heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

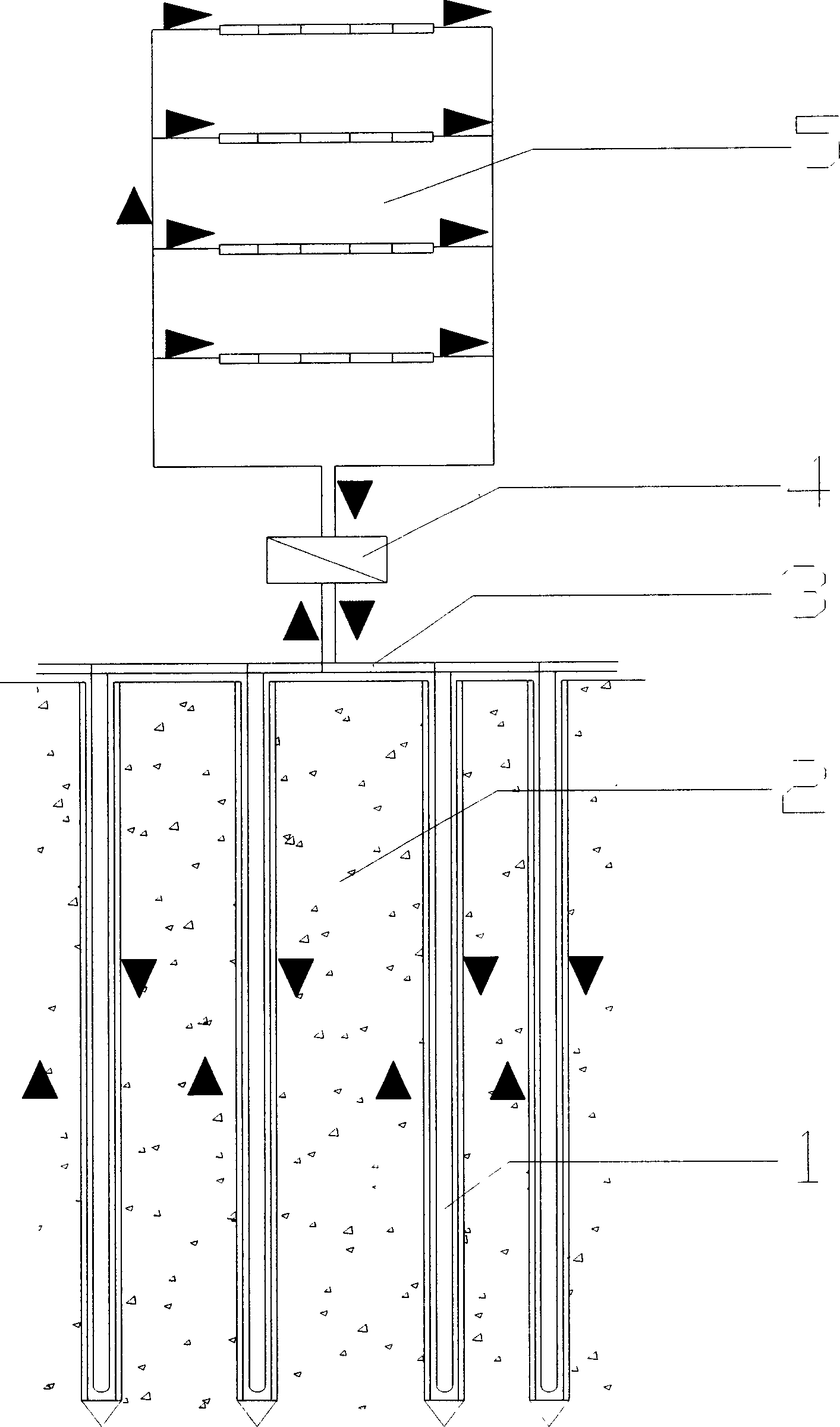

[0025] exist figure 1 Among them, the ground source heat pump utilizes the low-temperature potential heat energy of the shallow geothermal resources on the surface. In winter, the heat exchange fluid in the disc heat exchanger in the prestressed concrete pipe pile (1) converts the ground energy into the shallow soil layer (2) The heat in the building is extracted, and supplied to the building (5) for heating through the surface exchange pipeline (3) and the ground source heat pump unit (4); The heat exchange fluid in the ground source heat pump unit (4) and the tubular heat exchanger (1) in the prestressed concrete pipe pile is released into the shallow soil layer (2).

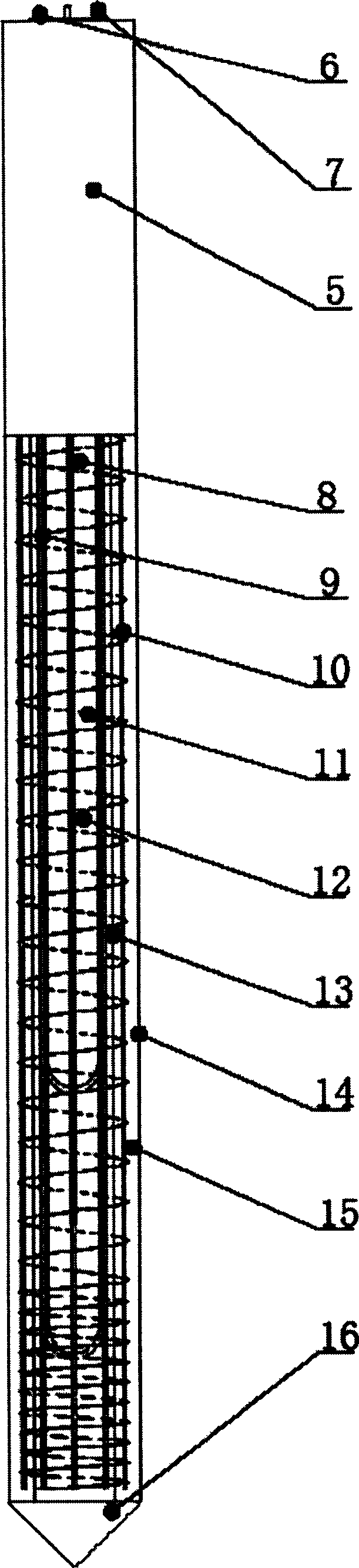

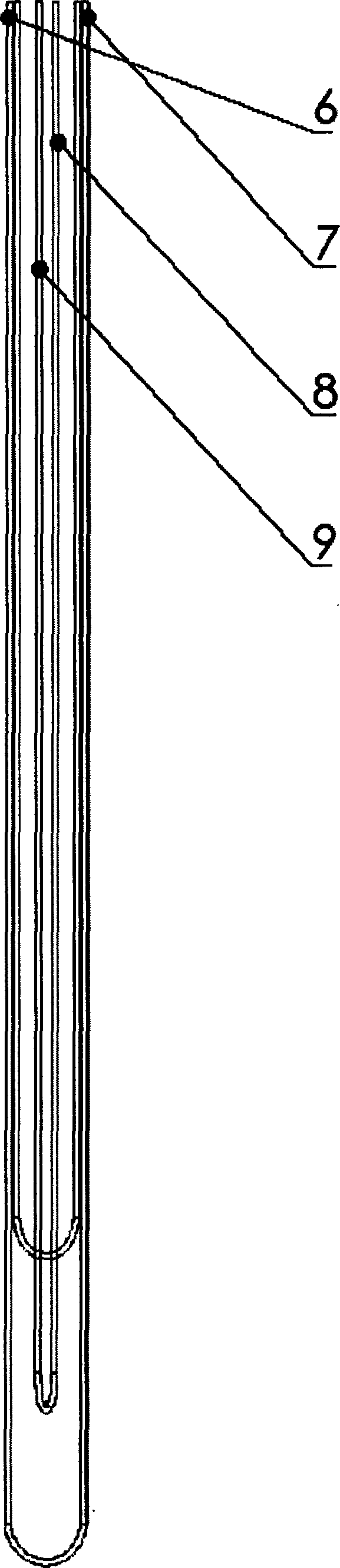

[0026] exist figure 2 In the shown embodiment, the ground energy conversion prestressed concrete pipe pile (1) has a variety of pipe diameters, and the reinforcement cage is formed by binding prestressed steel bars (10) and spiral stirrups (11). Concrete (15) is between (13,14), and the lower end of the pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com