Method for embedding precession-type backfill grouting ground source thermal energy conversion precast pile device into stratum

A technology of grouting behind the wall and ground source heat energy, applied in heat pumps, sheet pile walls, refrigerators, etc., can solve the problems of high pre-drilling cost, difficult development of ground source heat pump technology, complicated heat exchange tube process, etc. Low construction cost, convenient closed cycle conversion, and the effect of expanding the contact area of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

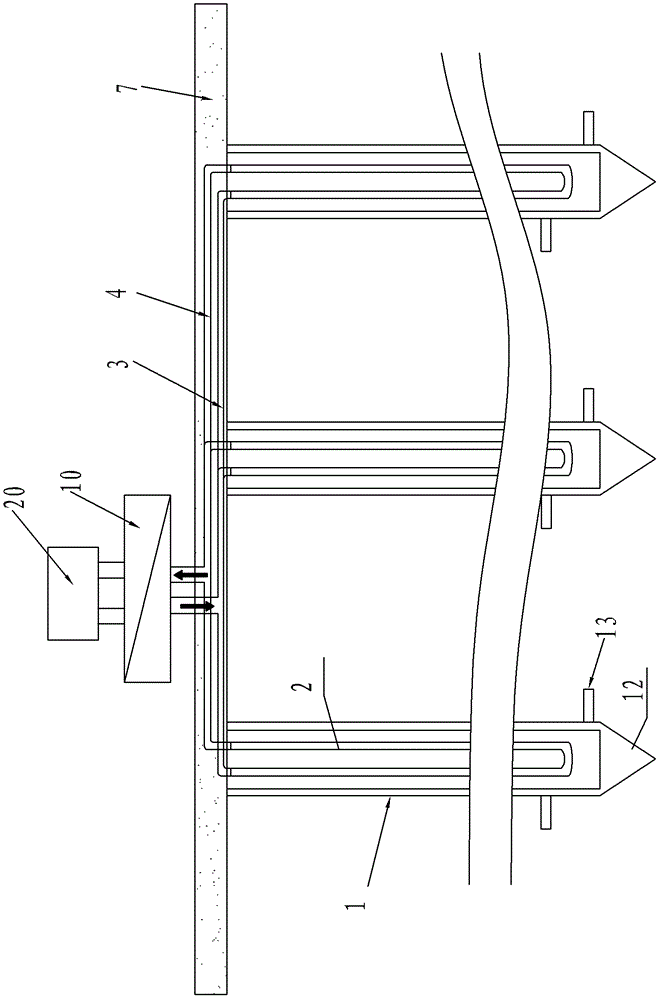

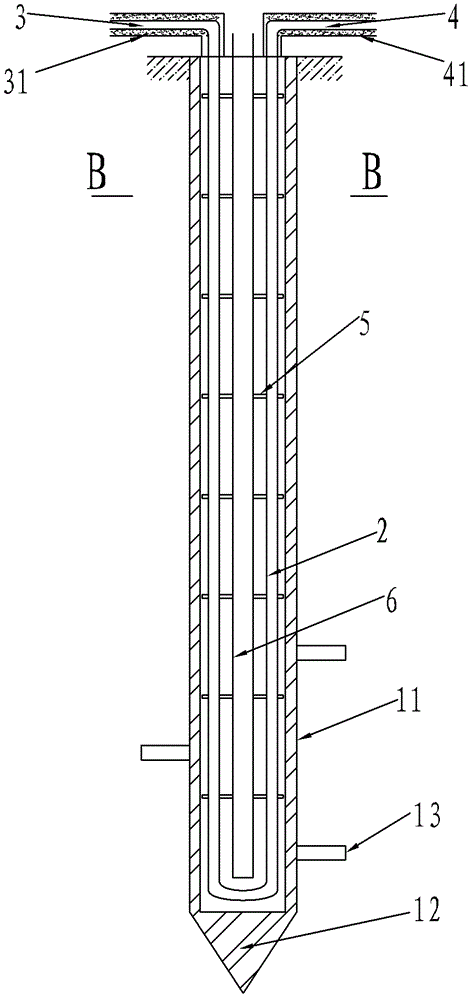

[0028] Such as figure 1 As shown, the screw-in type back-grouting ground source thermal energy conversion prefabricated pile device of the present invention includes several screw-in type back-grouting prefabricated screw piles 1 embedded in the pile holes, and each screw pile 1 is embedded with vertical Heat exchanger 2, the vertical heat exchanger 2 is a U-shaped vertical heat exchange tube, the inlet end and the outlet end of each vertical heat exchange tube protrude from the upper opening of the screw pile 1 respectively, and are connected with the horizontal liquid inlet header 3 and the horizontal liquid outlet respectively. Header 4 connections.

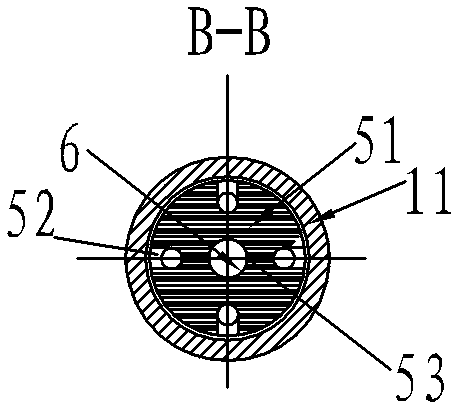

[0029] combine figure 2 , 3 As shown, the prefabricated screw pile 1 of screw-in type post-wall grouting includes a cylindrical hollow pile core 11, a conical pile head 12 is set at the bottom of the pile core 11, and a spiral blade 13 is set at the position 1-3m below the outer wall of the pile core 11. The grouting prefa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com