Method for preventing cyclone well from sinking when sealing bottom

A swirling well and bottom sealing technology, which is applied to caissons, buildings, and infrastructure engineering, can solve the problems of swirl well sealing bottom sinking, etc., and achieve the effect of convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

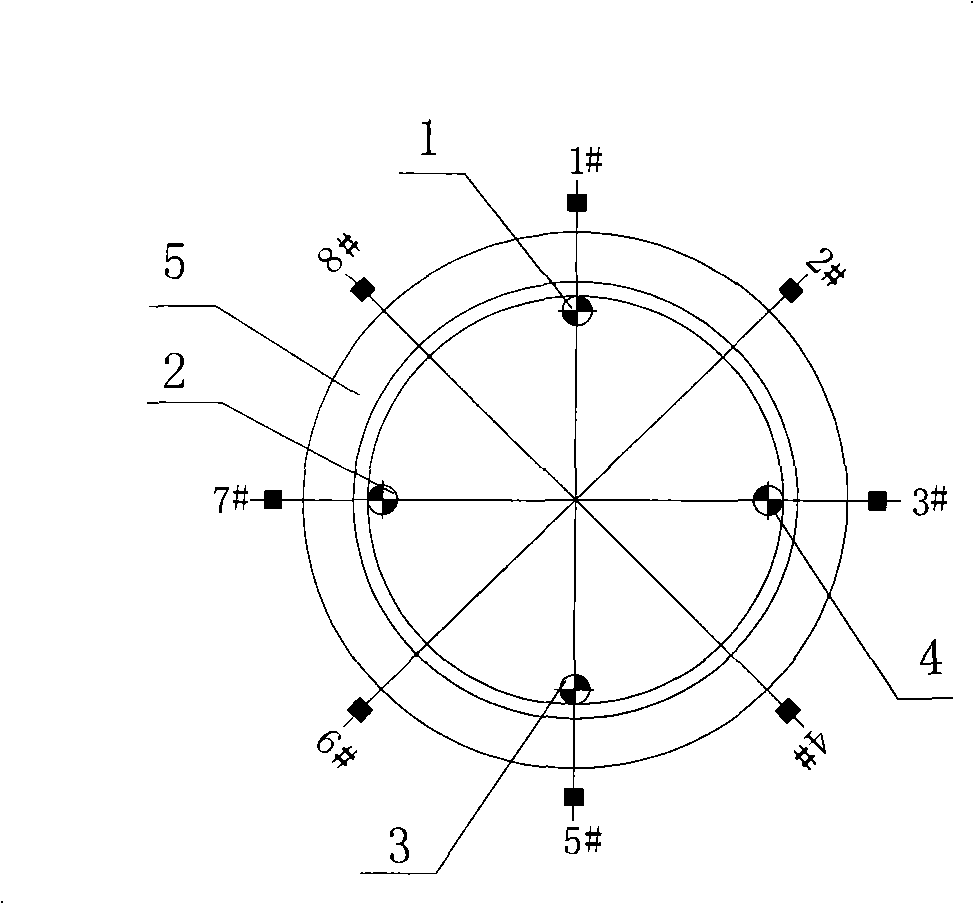

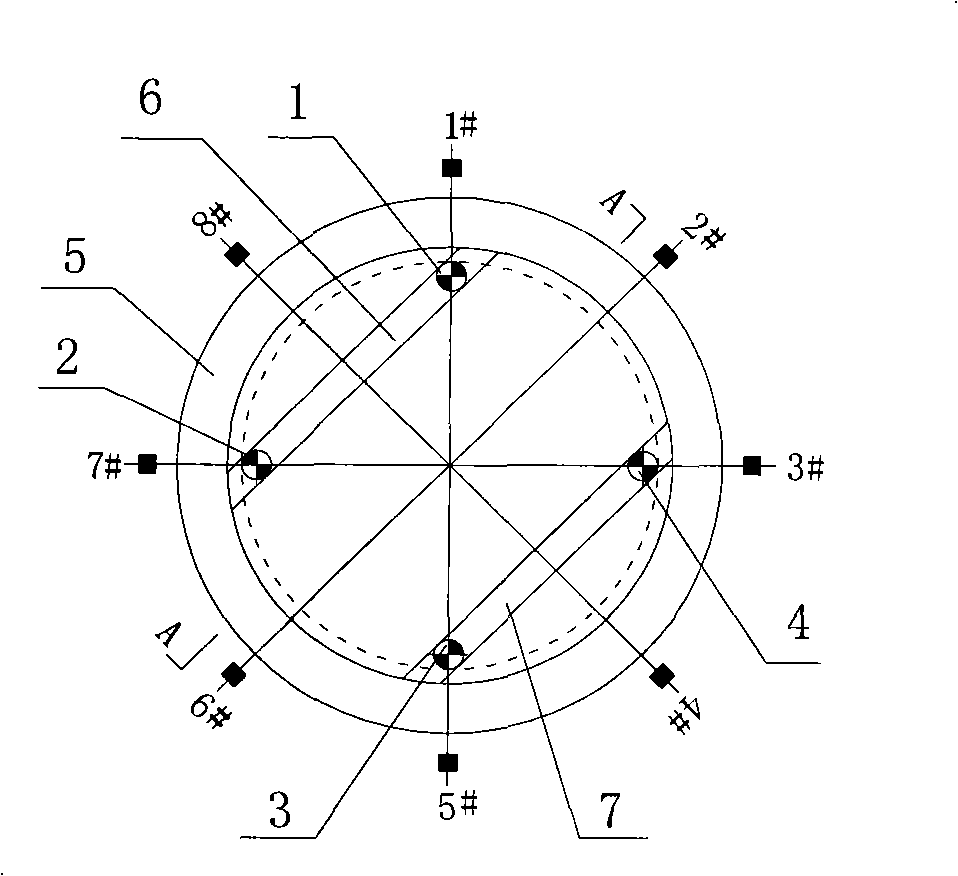

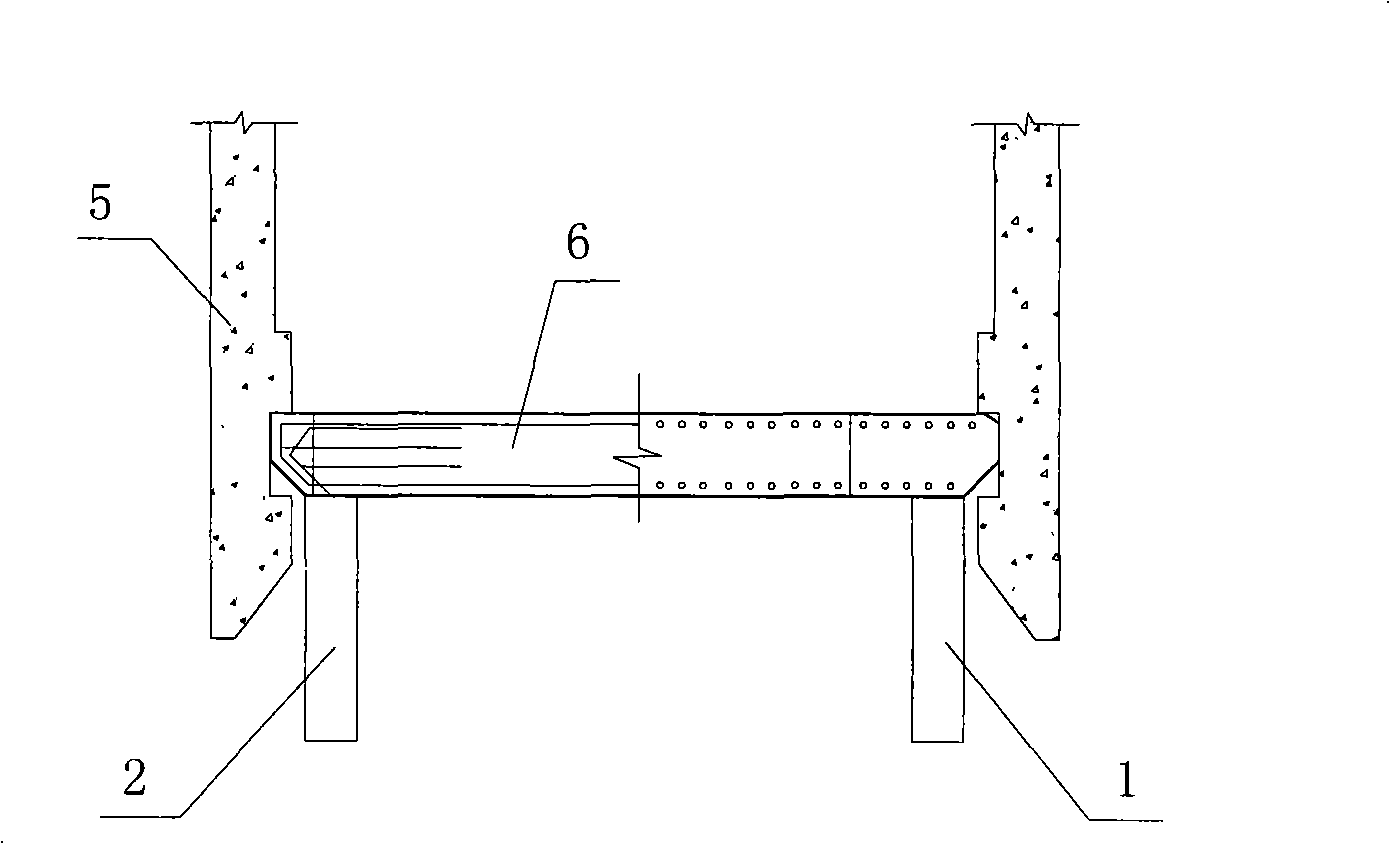

[0014] like figure 1 , figure 2 , image 3 As shown, the method for preventing the sinking of the swirl well when sealing the bottom includes the following steps:

[0015] 1) When the swirling well is dug to the bottom design elevation of the bottom cover, drill four cast-in-situ piles in the well (respectively the first pile 1, the second pile 2, the third pile 3, and the fourth pile 4), and the four cast-in-place piles The piles are arranged along the shaft wall 5 according to the settlement velocity and deviation (90° to each other), and the depths of the four cast-in-place piles respectively meet the rock-entry conditions;

[0016] 2), the bearing capacity of the four cast-in-place piles is greater than or equal to the difference between the self-weight and the frictional resistance of the shaft wall 5, and the frictional resistance is the frictional resistance between the shaft wall and the soil layer; then pour simply supported beams ( Cast the first simply supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com