Laminated lithium ion battery, battery pack comprising same and pole piece of laminated lithium ion battery

A lithium-ion battery and lamination technology, which is applied in the direction of non-aqueous electrolyte battery electrodes, battery pack components, secondary batteries, etc., can solve the problems of battery electrical performance degradation, battery performance changes, battery explosion, etc., to achieve current collectors The effects of increased area, reduced internal resistance, and good heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

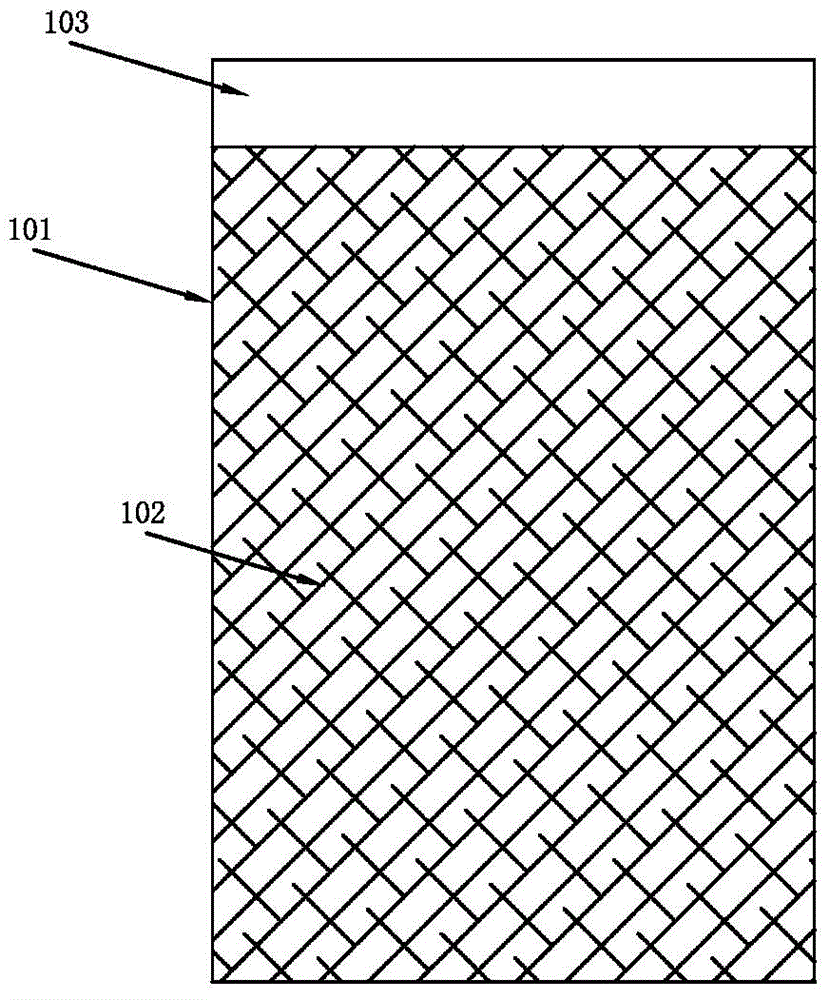

[0067] see figure 1 As shown, this embodiment provides a pole piece suitable for laminated lithium-ion batteries, the pole piece comprising: a current collector 101 , and an active material layer 102 coated on the current collector 101 .

[0068] The active material layer 102 is coated to the end of the first width end of the pole piece, and a continuous uncoated area 103 is reserved at the end of the second width end of the pole piece. The front and bottom surfaces of the uncoated area are both The active material layer 102 is not coated, and the current collector 101 located in the uncoated area 103 is exposed. When applying the pole piece, the exposed current collector 101 can be used as the tab of the pole piece without additional welding of the tab.

[0069] The length of the exposed current collector 101 in this embodiment can be predetermined, and the length of the exposed current collector 101 can be made longer so that it can be bent and welded to external components....

Embodiment 2

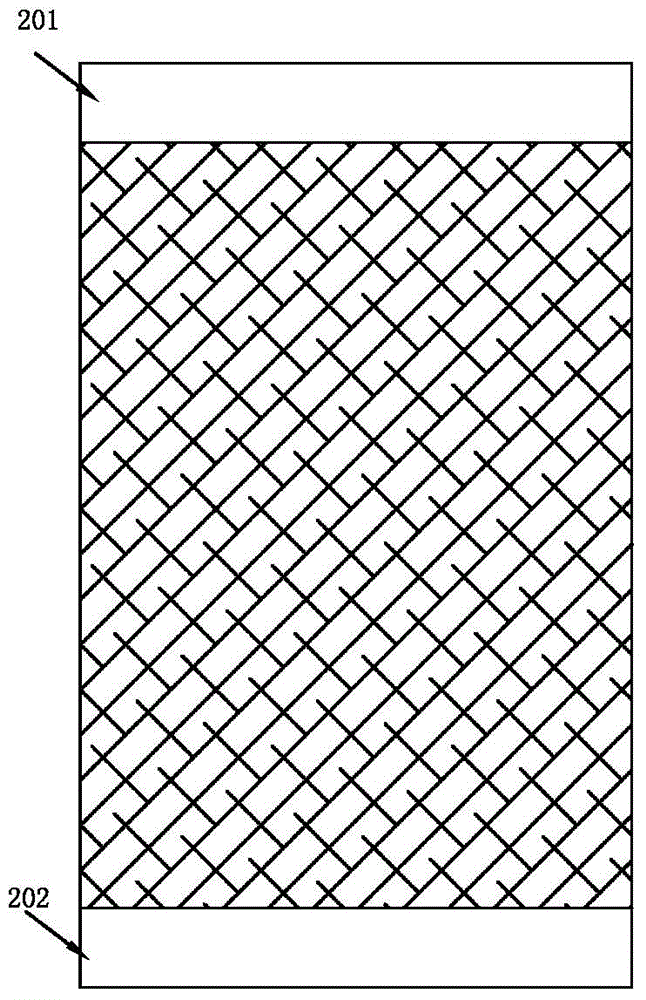

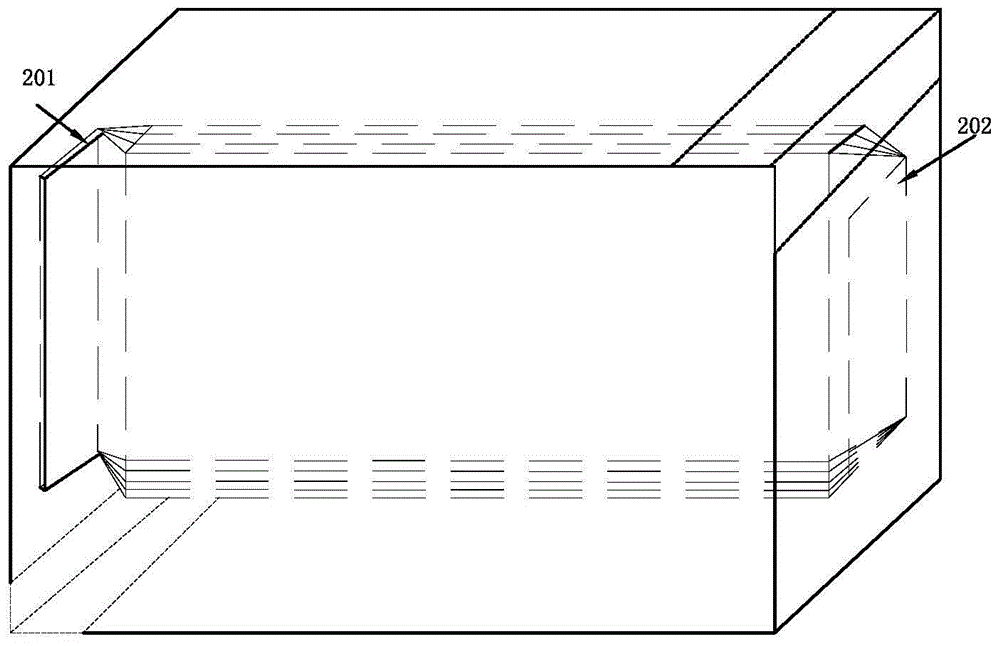

[0077] see Figure 2-5 As shown, this embodiment provides a structure in which the positive electrode sheet and the negative electrode sheet of the structure described in Embodiment 1 are used to make a laminated lithium ion battery core body.

[0078] see figure 2 As shown, in this embodiment, the current collector of the positive electrode sheet is marked as the first current collector, and at the end of a width end of the positive electrode sheet, the exposed first current collector can be used as the tab of the positive electrode sheet (i.e., the positive electrode ear 202 ). The current collector of the negative electrode sheet is referred to as the second current collector, and the exposed second current collector section at one width end of the negative electrode sheet can be used as the tab of the negative electrode sheet (ie, the negative tab 201 ).

[0079] The positive electrode sheet and the negative electrode sheet are stacked together by lamination technology,...

Embodiment 3

[0090] see Figure 6 As shown, this embodiment provides a lithium-ion battery pack composed of the laminated lithium-ion batteries described in Embodiment 2.

[0091] When utilizing the stacked lithium-ion batteries of Embodiment 2 to form a lithium-ion battery pack in series, each lithium-ion battery can be arranged face-to-face and arranged together to form a lithium-ion battery pack. Specifically, for any adjacent two stacks Lithium-ion batteries, the first metal panel 501 of the shell of a laminated lithium-ion battery is in contact with the second metal panel 401 of the shell of another laminated lithium-ion battery face to face, and the laminated lithium ion battery can be realized. A series connection between ion batteries. It can be seen that when the laminated lithium-ion battery of this embodiment is used to form a battery pack, since the positive and negative poles of the battery are the plane of its housing, the batteries only need to be in face-to-face contact to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com