Expiratory valve

A technology of exhalation valve and valve body, which is applied in the field of exhalation valve, can solve the problems of difficult cleaning and replacement, inconvenient disinfection, etc., and achieve the effect of low cost, easy cleaning and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

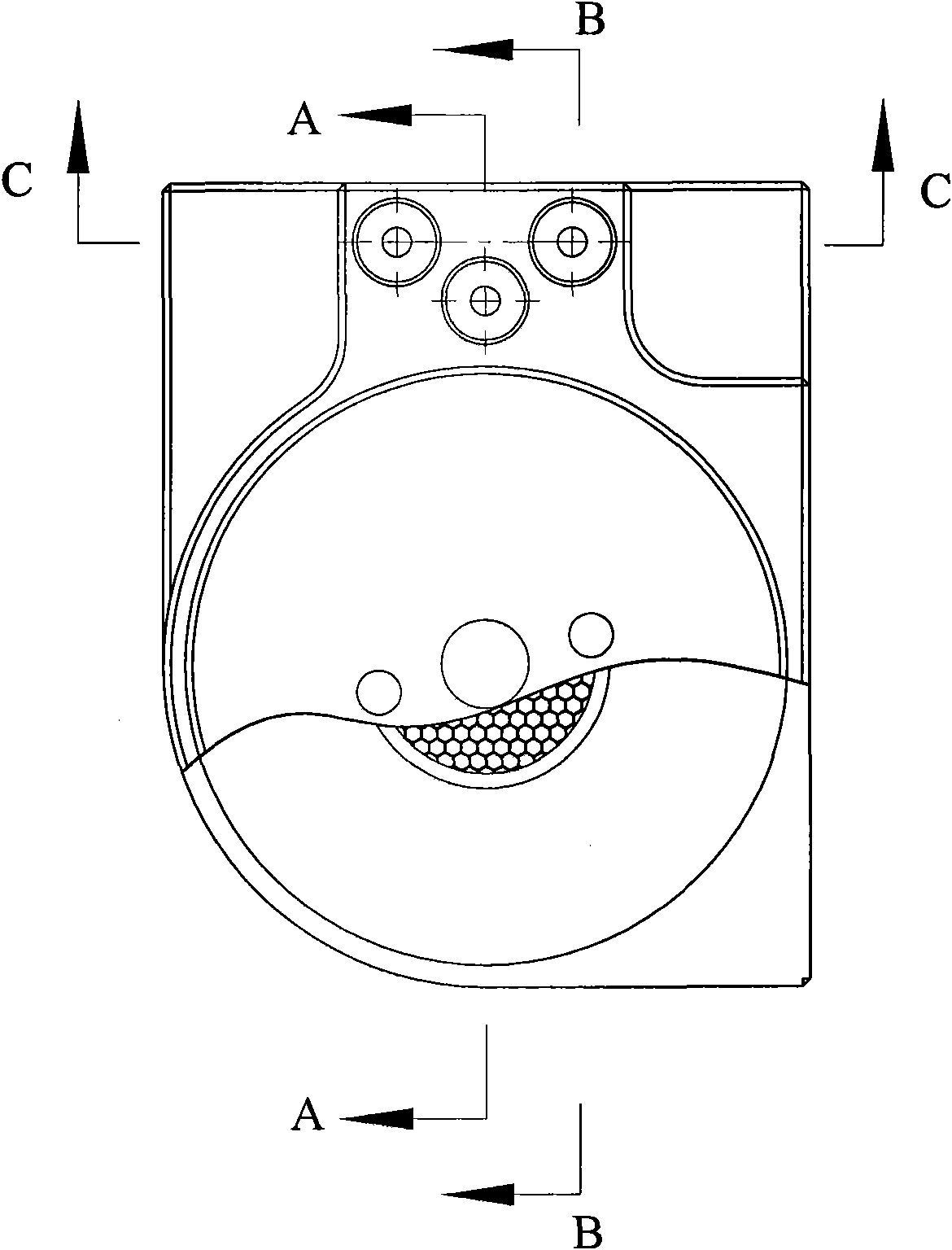

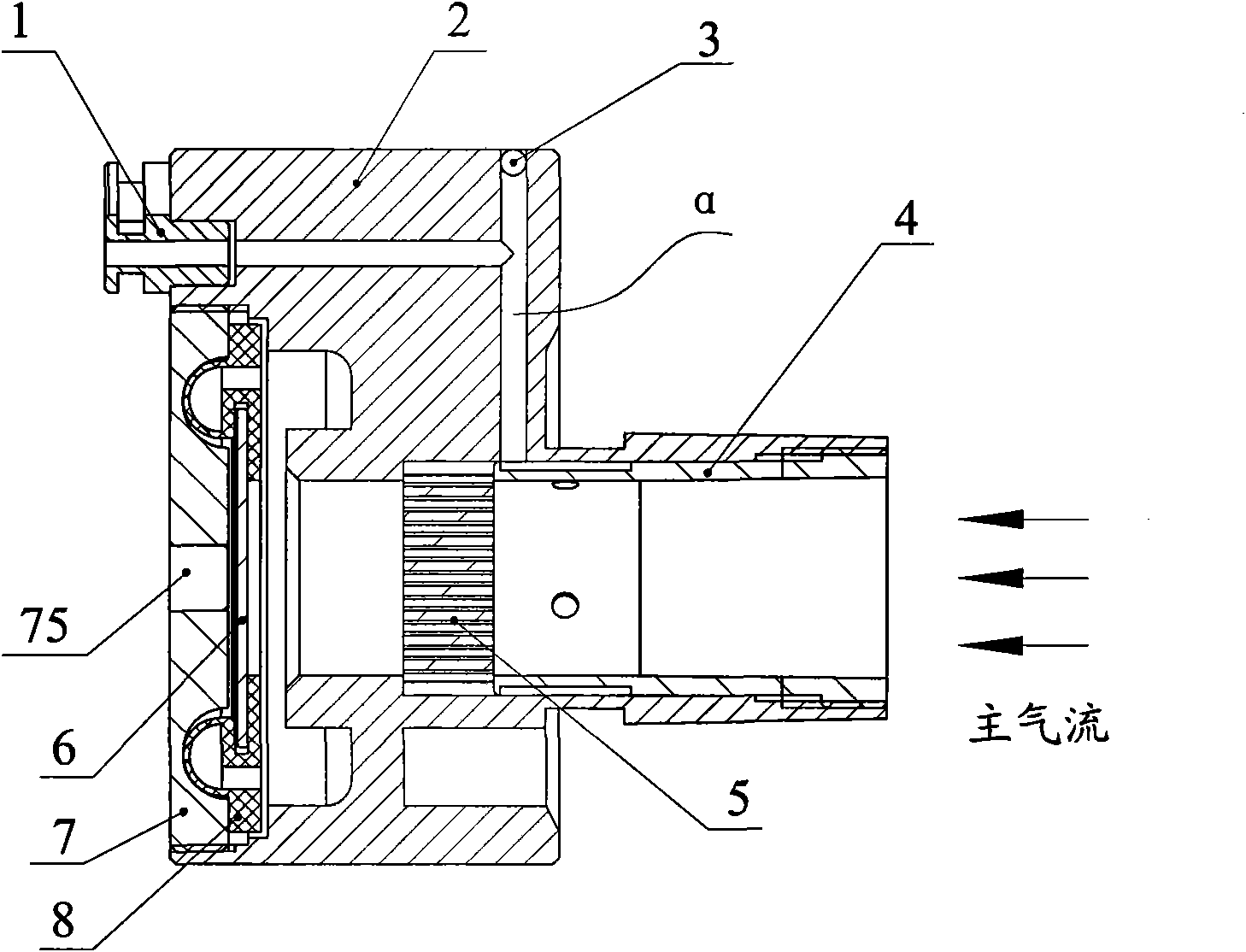

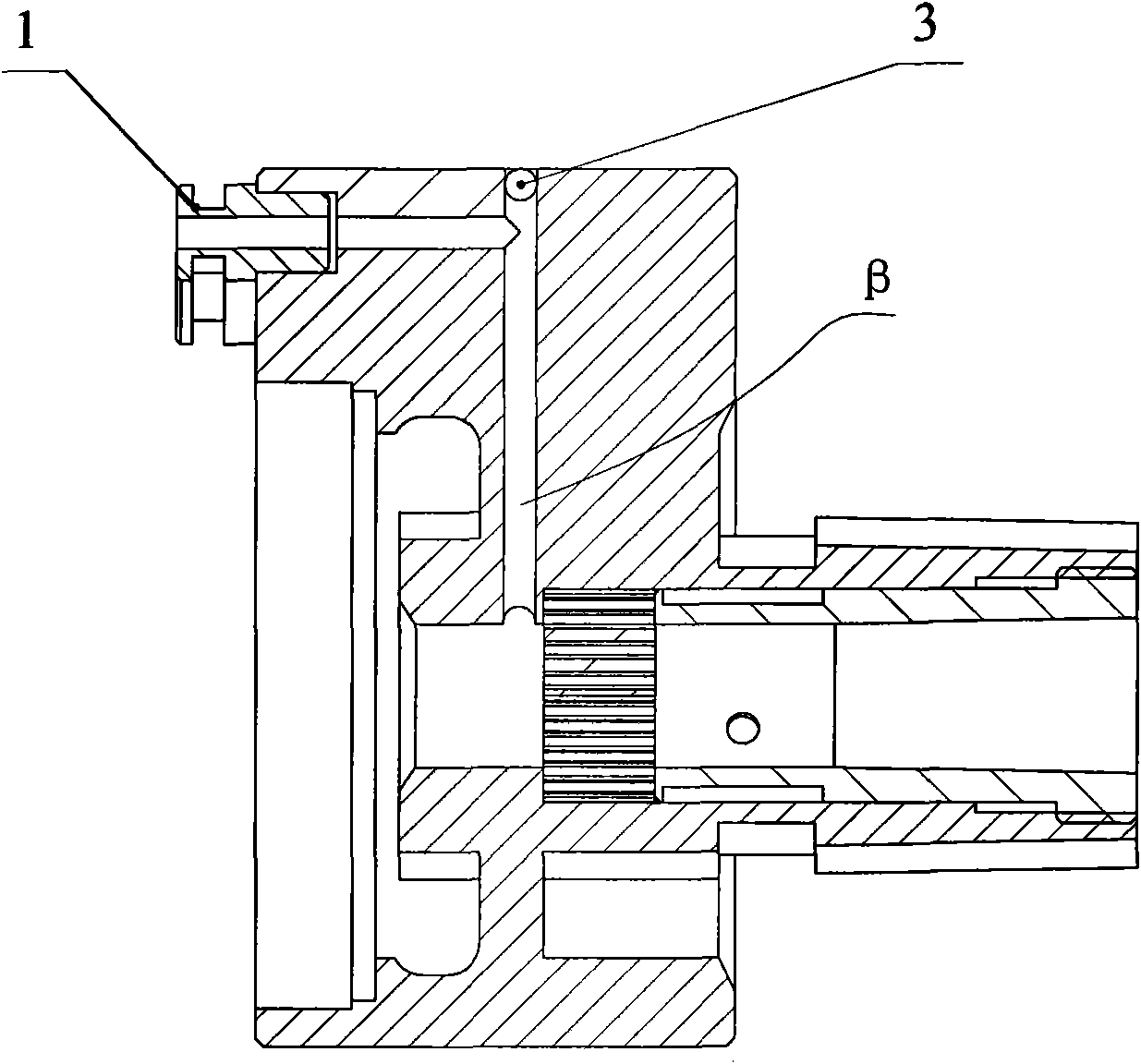

[0026] Such as Figure 1 to Figure 4 As shown, the exhalation valve used in a ventilator according to the present invention includes a valve body 2, a top sleeve 4, a linear air resistance 5, a valve cover 7, a diaphragm 8, a diaphragm baffle 6, a mouthpiece 1 and a ball plug 3. Such as figure 2 As shown, the patient's expiratory airflow from figure 2 The direction of the three arrows in flows into the main road and passes through the linear air resistance 5 . In order to make the gas flowing through the main path change from laminar flow to turbulent flow, and to facilitate more accurate sampling, the linear air resistance 5 is provided with many mesh-like small holes (such as Figure 7 shown).

[0027] The valve body 2 is the base that carries the other parts and is usually made of aluminium. Such as Figure 5c As shown, the valve body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com