Feed device of minor-diameter rodlike workpiece processing equipment

A technology for processing equipment and feeding devices, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as equipment failure, poor strength, and easy breakage, so as to improve operation reliability and reduce breakage failure, the effect of reducing sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

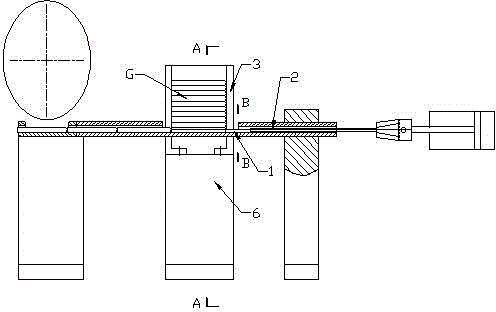

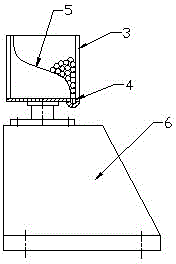

[0013] As shown in the figure, the feeding device of the small-diameter rod-shaped workpiece processing equipment includes a horizontal material guide groove 1 whose front end is connected with the cutting device components. The push rod 2 that moves axially in the groove, the material box 3 is arranged above the material guide groove, the bottom of the material box is provided with the discharge port 4 facing the material guide groove and allowing the rod-shaped workpieces G to pass through one by one, and the material box is set There is a guide inclined surface 5 that can make the bar-shaped workpiece roll to the discharge port under the action of gravity; the material box 3 is placed on a vibrating device 6 and can vibrate up and down with the vibrating device.

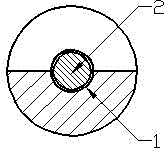

[0014] Such as image 3 As shown, in this embodiment, the cross-sectional shape of the material guide groove 1 is a semicircle suitable for the diameter of the rod-shaped workpiece, and the cross-section of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com