Smart well interval control valve

A technology for controlling valves and smart wells, which is applied in wellbore/well valve devices, wellbore/well components, earthwork drilling and production, etc., which can solve the problem of not being able to control the reservoir, only opening or closing, time-consuming, laborious and costly, etc. problem, to achieve the effect of low production cost, avoid manual intervention, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

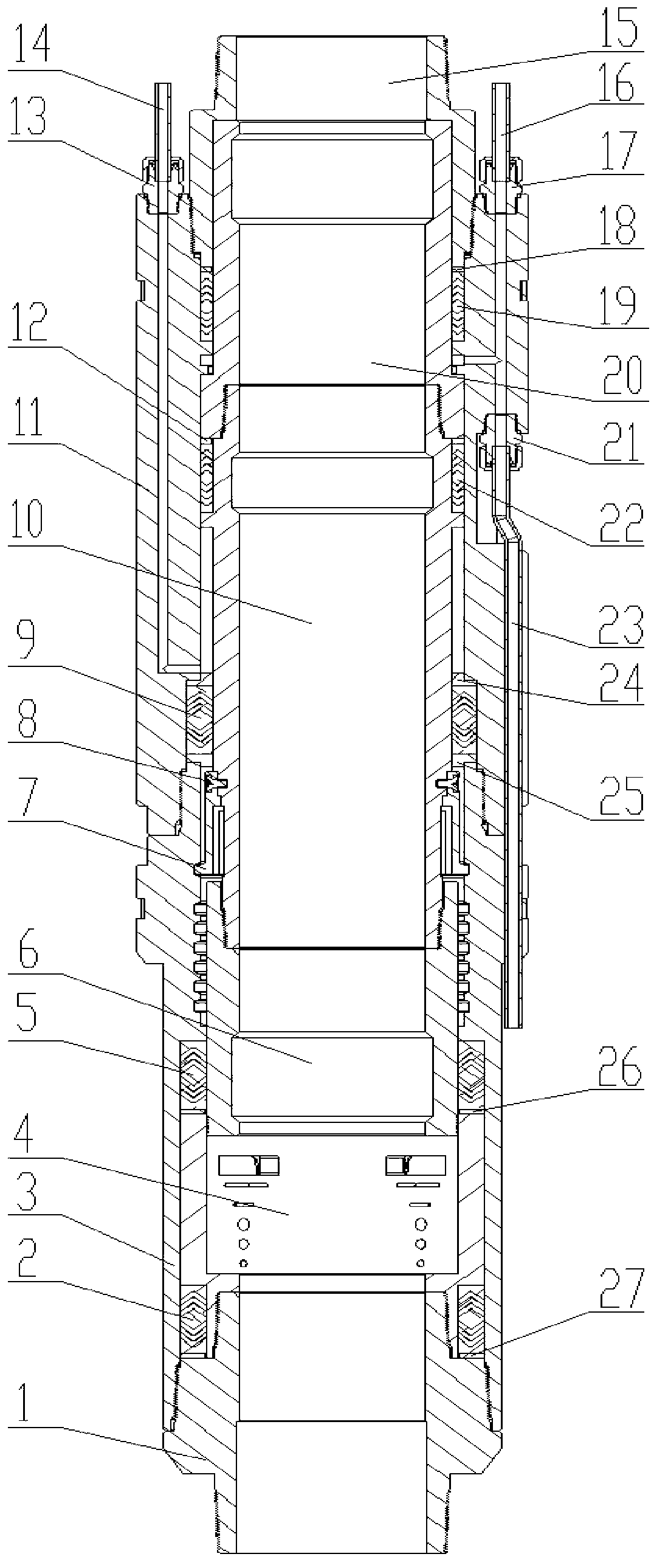

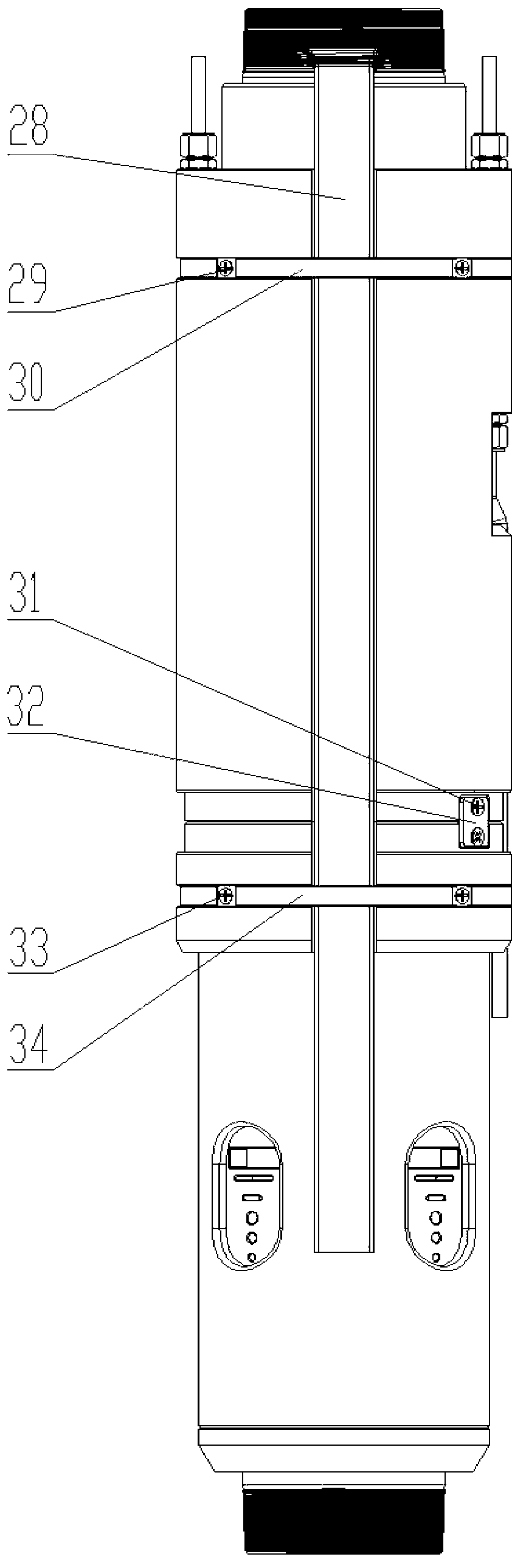

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] refer to Picture 1-1 and Figure 1-2 , an intelligent well interval control valve, comprising a sliding sleeve 6 installed in a fluid restrictor 4, the sliding sleeve 6 can slide in the fluid restrictor 4, and the sliding sleeve 6 is processed with a sealing groove and a fluid The restrictor 4 forms a metal seal, and the sliding sleeve 6 cooperates with the fluid restrictor 4 to open / close different holes to control the amount of fluid entering. The fluid restrictor 4 is fixed on one end of the lower joint 1 through threaded connection, and the lower joint 1 This end of the lower joint 1 is connected to the lower cylinder body 3 of the layer control valve through threads, and the other end of the lower joint 1 is connected with other oil pipe strings through a threaded connection of the oil pipe collar. The lower joint 1, the fluid restrictor 4 and the layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com