Degradable alloy and application of degradable alloy serving as single-slip-type soluble bridge plug

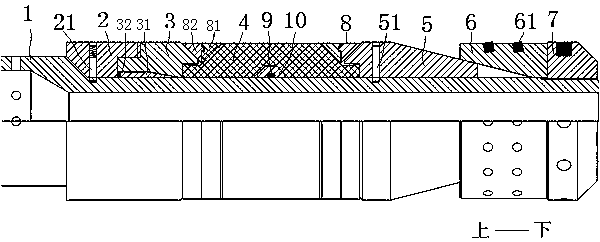

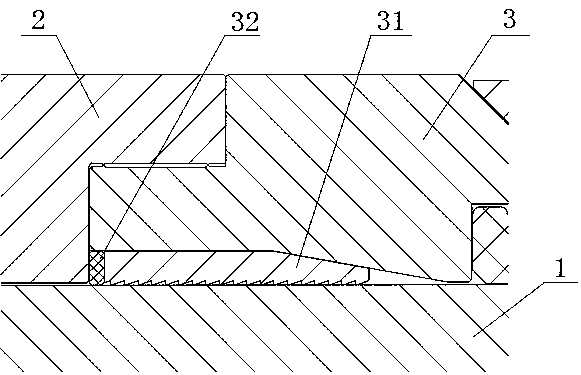

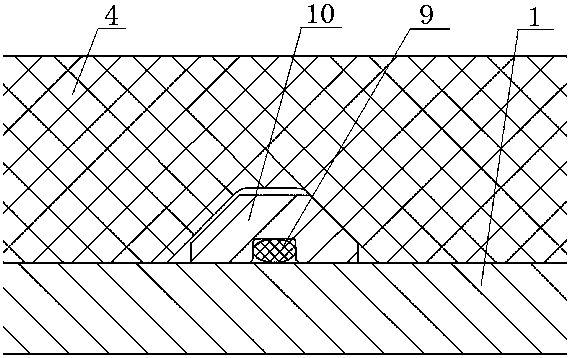

A single-slip, slip-type technology, applied in wellbore/well components, earthmoving, sealing/packing, etc., can solve the work requirements of single application range, short degradation time, and inability to meet long-term dissolution and other problems, so as to solve the problems of easy jamming, excellent sealing performance and pressure bearing performance, and controllable corrosion time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment one, a kind of degradable alloy, it comprises following components:

[0034] Zn is 70%, Mg is 15%, Na is 9.5%, Fe is 3%, C is 0.5%, Si is 1%, Ni is 1%, and unavoidable impurities.

Embodiment 2

[0035] Embodiment two, a kind of degradable alloy, it comprises following components:

[0036] Zn is 65%, Mg is 15%, Na is 10%, Fe is 5%, C is 0.5%, Si is 2%, Ni is 2%, and unavoidable impurities.

Embodiment 3

[0037] Embodiment three, a degradable alloy, which includes the following components:

[0038] Zn is 75%, Mg is 5%, Na is 10%, Fe is 5%, C is 0.5%, Si is 2%, Ni is 2%, and unavoidable impurities.

[0039] The rigidity of the soluble bridge plugs prepared by using the degradable alloys of Example 1, Example 2, and Example 3 is doubled or more than that of conventional soluble bridge plugs with Mg as the main body of the alloy material. Under the condition of 60°C, the maximum pressure is 120 MPa, the pressure stabilization time is 2 days or more, and the total dissolution time is 10 days or more. Under the condition of 120°C, the maximum pressure is 100 MPa, the pressure stabilization time is 6 hours or more, and the total dissolution time is 3 days or more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com