Horizontal large nut erector

A large nut and installer technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as jamming, difficulty in installing and rotating large nuts, and difficulty in installing nuts, so as to solve the problem of increased friction and large The effect of the one-sided force problem on the nut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

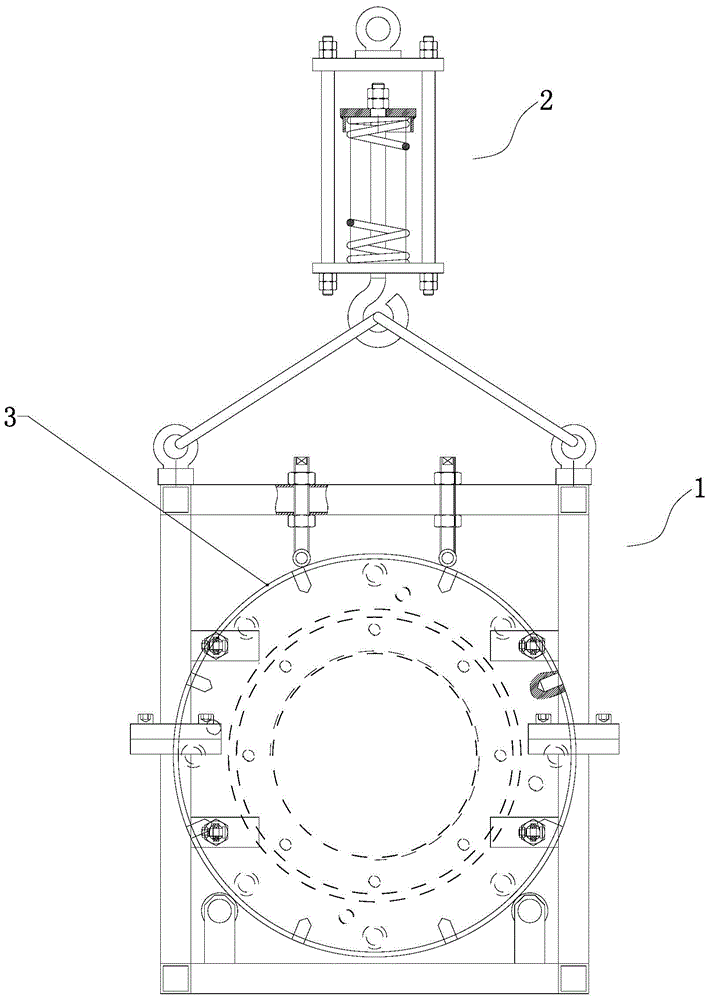

[0023] Such as figure 1 and figure 2 As shown, the horizontal large nut installer of the present invention consists of a rotator 1 and a buffer 2.

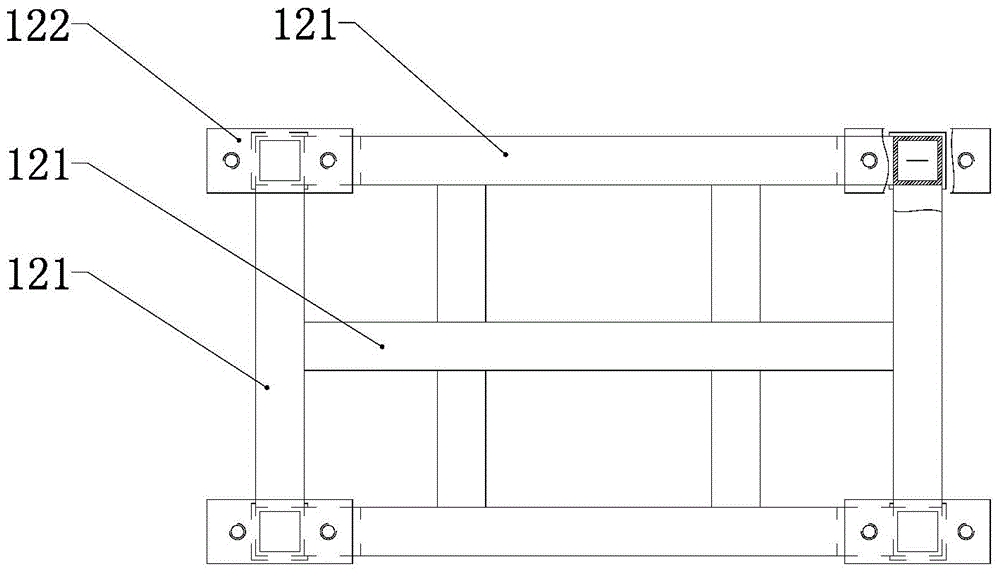

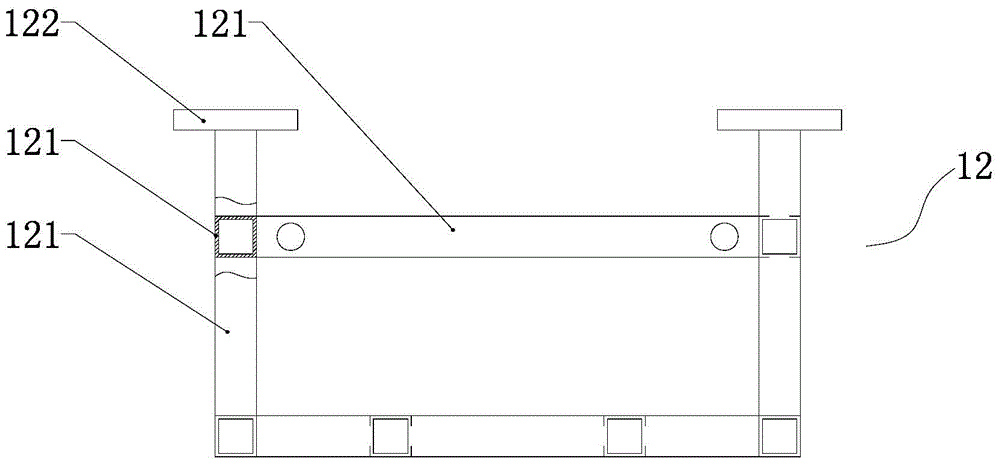

[0024] The rotator 1 is mainly composed of a support frame in the shape of a cuboid and a plurality of bearings 13 arranged on the frame. The support frame is movably connected by an upper support frame 11 and a lower support frame 12 . Wherein, the lower supporting frame 12 is mainly a rectangular parallelepiped frame formed by a plurality of square tubes 121 , and a connecting plate 121 is respectively fixed to the ends of the square tubes on four sides. The structure of the upper supporting frame 11 is the same as that of the lower supporting frame, and two hanging rods 111 are provided on its upper end surface. The upper support frame 11 and the lower support frame 12 constitute the whole support frame through the joining of the connecting plates on four sides, and form a placement area for placing large nuts in the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com