Wire leading structure capable of automatically inserting wire

A wire and automatic technology, applied in the field of winding wire structure and motor automatic embedding, can solve the problems of high cost and large space occupation, and achieve the effect of less space occupation, reduced sliding friction, and easy to be pulled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

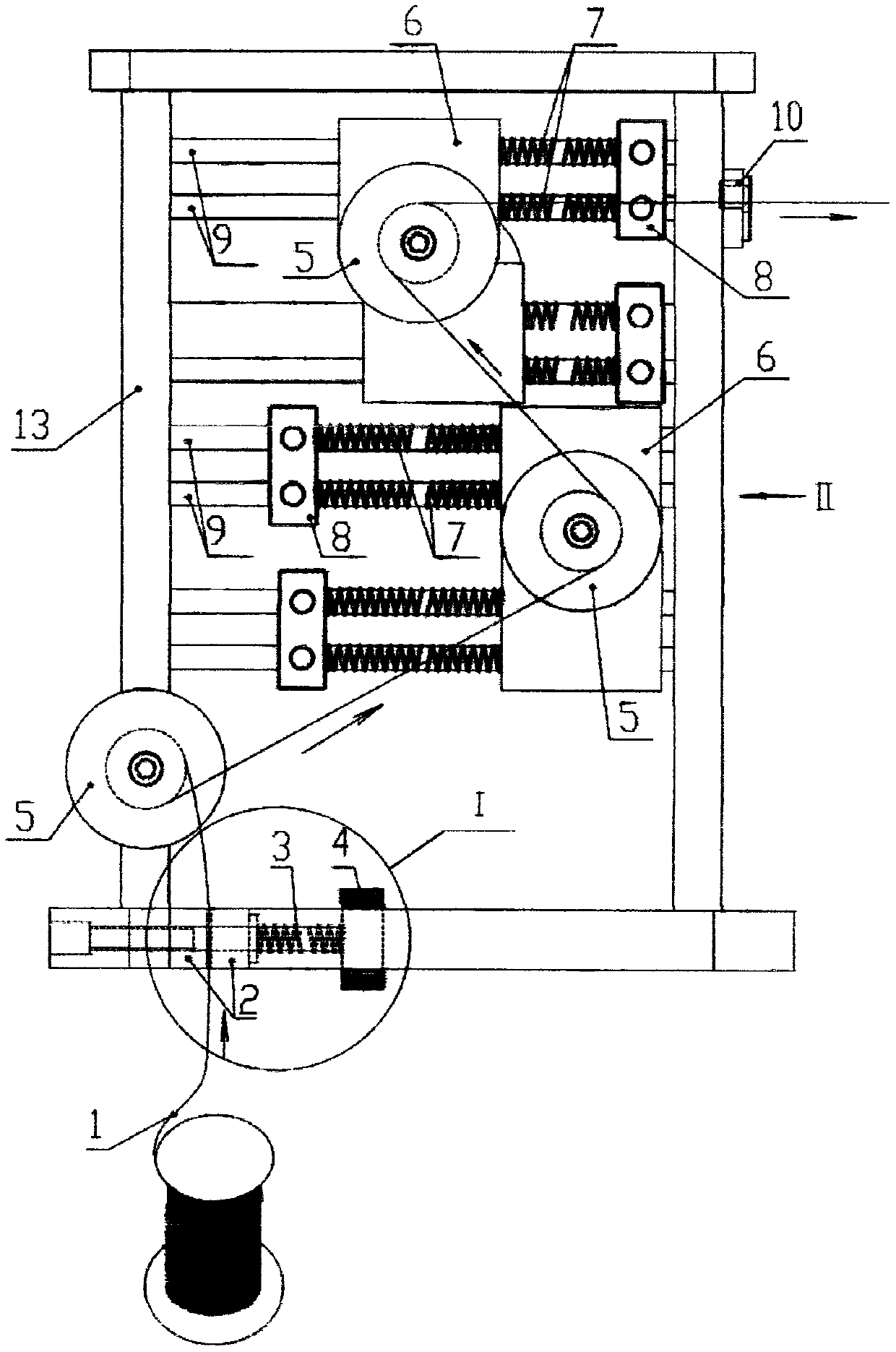

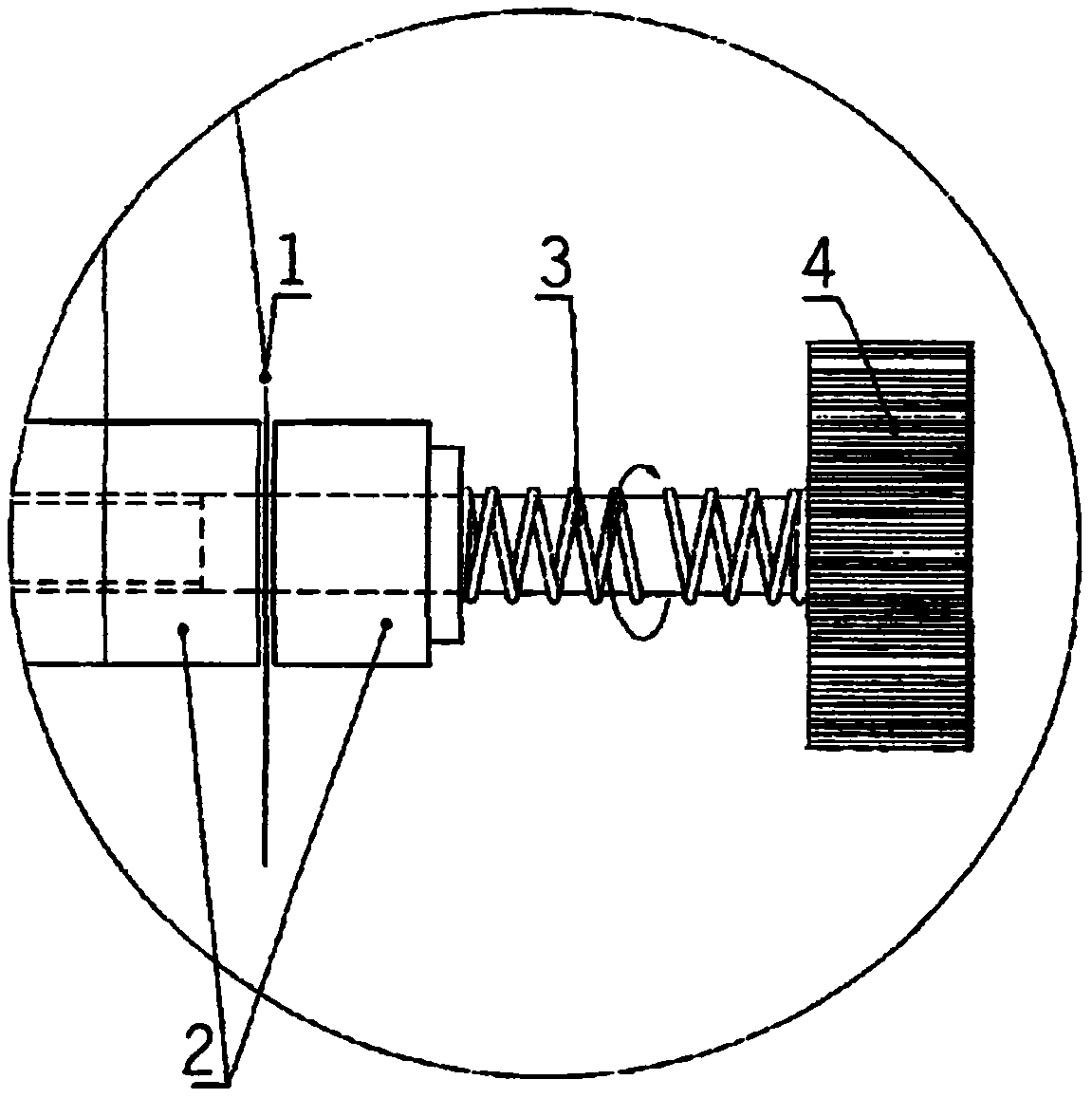

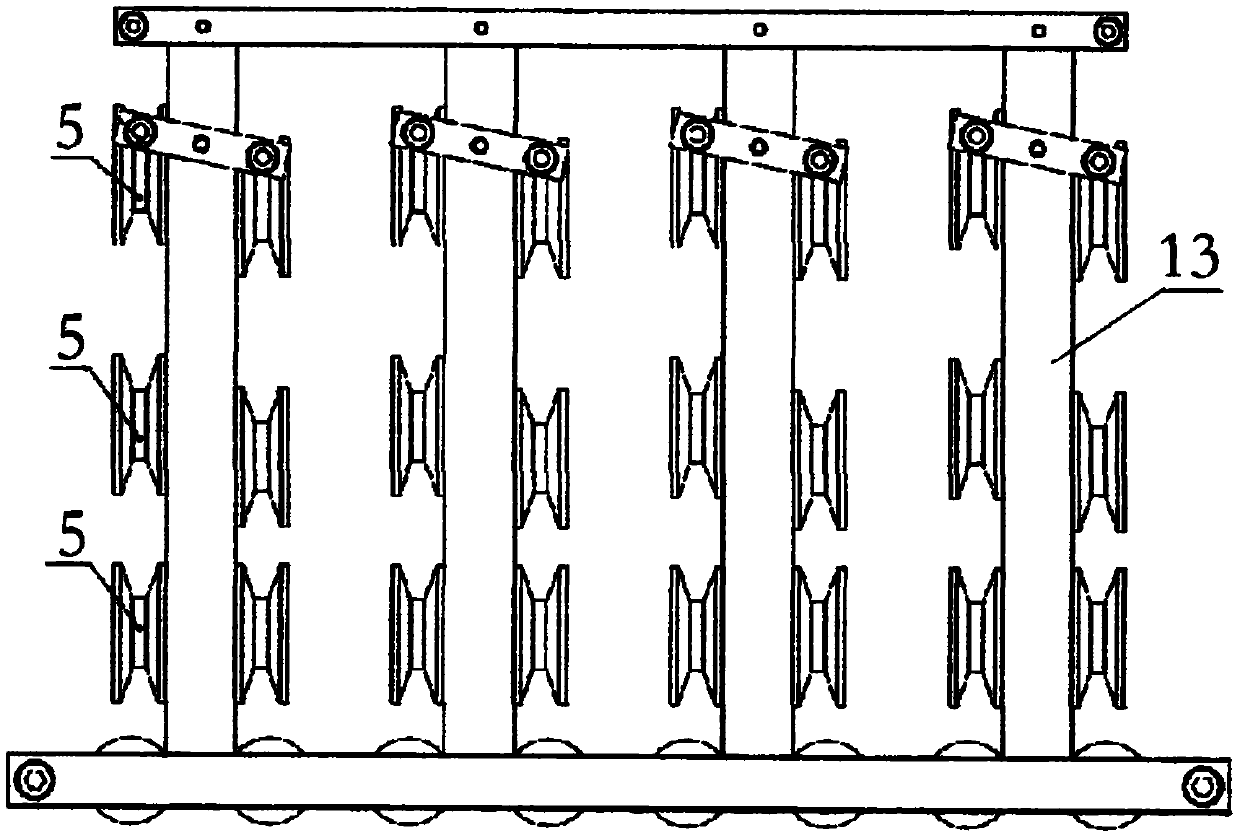

[0020] The present invention will be described in detail below with reference to the accompanying drawings.

[0021] As shown in Figure 1, it is a kind of wire structure of automatic embedding, which has a frame-type main frame 13, and multiple groups of independent wire structures of automatic embedding are installed on the main frame 13 (see figure 2 ). The wire structure of each group of automatic wire insertion includes a wire inlet device, a wire wheel 5, a guide slider 6, a compression spring 7, an adjustment block 8, a shaft 9 and a porcelain eye 10. see Figure 1-2 , The wire inlet device is made of wool felt 2, damping spring 3 and damping fine-tuning handle 4, and the wire inlet device is installed on one side of the bottom of the main frame 13. The wool felt 2 is two pieces, and there is a gap in the middle for the enamelled copper wire 1 to pass through. The wool felt 2 is supported by the damping spring 3 on one side, and the damping spring 3 is supported and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com