Automatic weighing and gathering sorting machine and goods gathering and straightening method

An automatic weighing and sorting machine technology, applied in the field of logistics, can solve the problems of narrow-band offset and change of the direction of goods conveying, and achieve the effect of compact structure, ensuring consistency and reducing labor loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

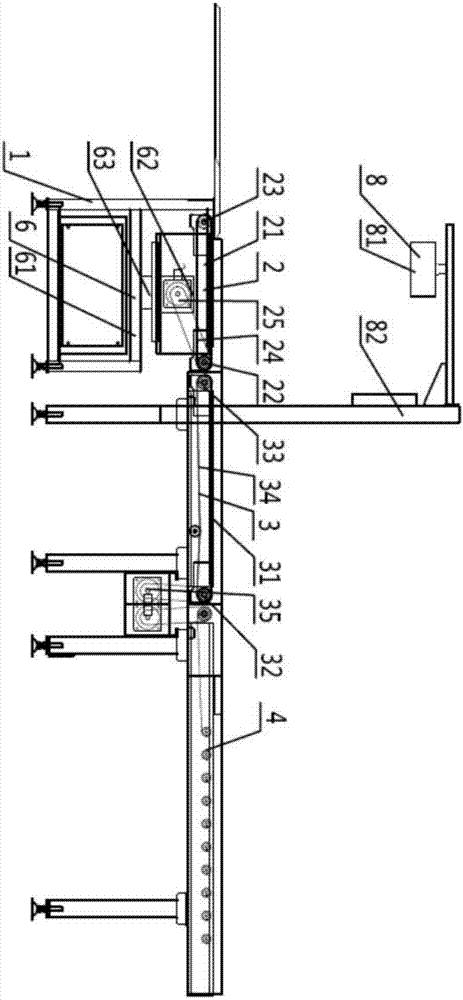

[0041] like Figure 1 to Figure 3 As shown, the present invention discloses an automatic weighing merge sorter, including a frame 1, and the frame 1 is sequentially connected with a first station 2, a second station 3 and a third station 4;

[0042] The first station 2 includes a first conveying device 21 and a weighing device 6 for weighing the goods on the first conveying device 21; the weighing device 6 at least includes a base 61 and is arranged on the The cover plate 62 above the base 61, the base 61 and the cover plate 62 are connected by a pressure sensor 63; the cover plate 62 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com