Fluidized bed adsorption-fluidized bed desorption coupled efficient VOCs (volatile organic compounds) treatment system and method

A technology of a treatment system and an adsorption system, applied in the field of organic waste gas treatment, can solve the problems of difficulty in fully utilizing the saturated adsorption capacity of the adsorbent, poor adsorption capacity of the adsorbent, and difficulty in realizing the replacement and renewal of the adsorbent, so as to solve the problems of uneven adsorption, The effect of efficient desorption and reduction of labor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

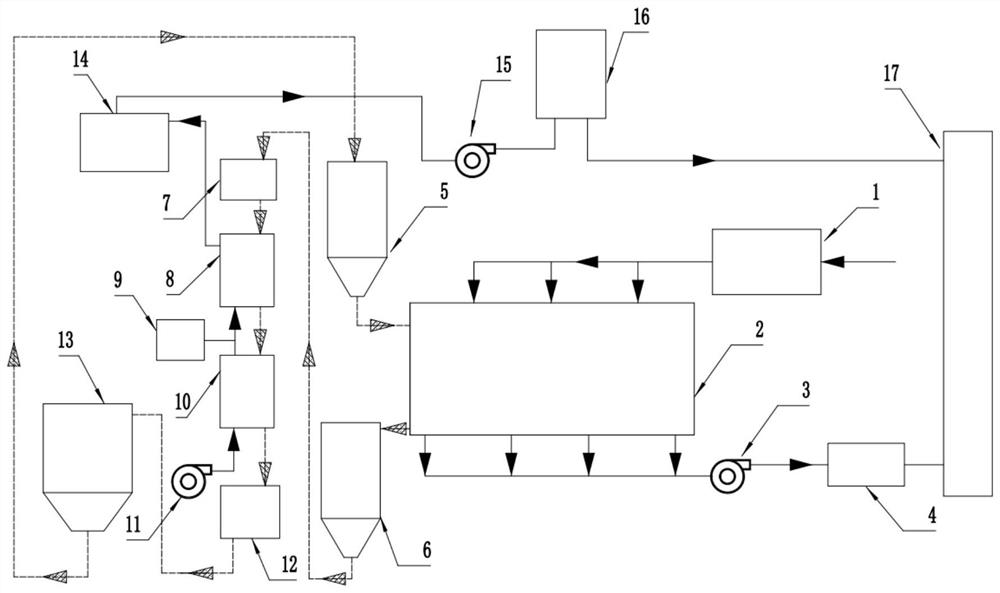

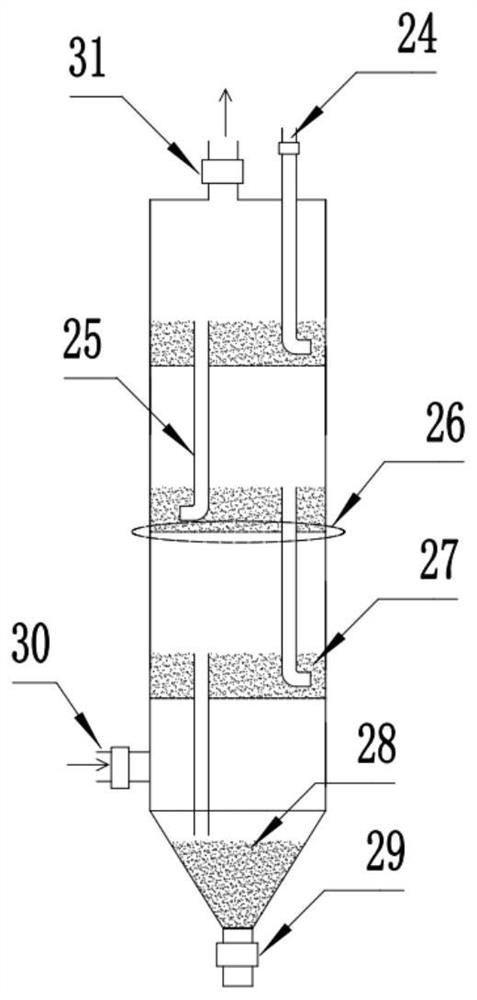

[0055] Such as Figure 1~3 As shown, the fluidized bed adsorption-fluidized bed desorption coupling high-efficiency VOCs treatment system suitable for the treatment of organic waste gas with large air volume and low concentration of VOCs in this embodiment includes automatic inlet and outlet adsorption system, multi-stage fluidized bed desorption System and desorption exhaust gas treatment system for mineralization or recovery of desorption exhaust gas. The automatic feeding and discharging adsorption system includes an adsorption box 2 . The desorption exhaust gas treatment system includes a dedusting device 14 , a desorption fan 15 and a VOCs treatment device 16 for mineralizing VOCs connected in sequence, and the outlet pipe of the VOCs treatment device 16 is connected to an exhaust cylinder 17 .

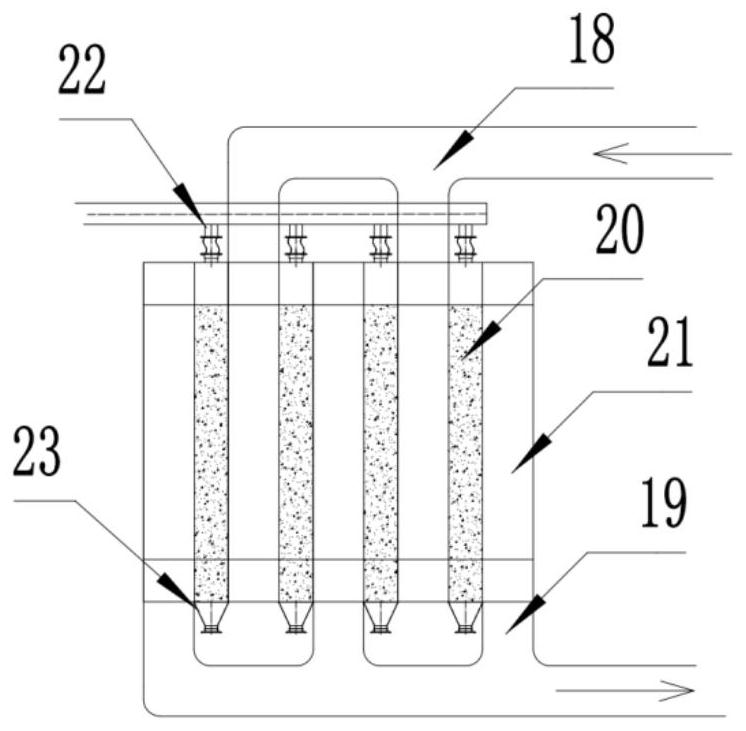

[0056] Such as figure 2 As shown, the adsorption box 2 is provided with several alternately arranged air distribution boxes 21 and adsorbent layers 20; one end of the air dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com