Full-automatic production line for halogen lamp

A fully automated, production line technology, applied in electrical components and other directions, can solve the problems of inability to achieve fully automated halogen lamp production, lack of wire threading machines, etc., and achieve the effects of reducing labor loss, fast mechanical action, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

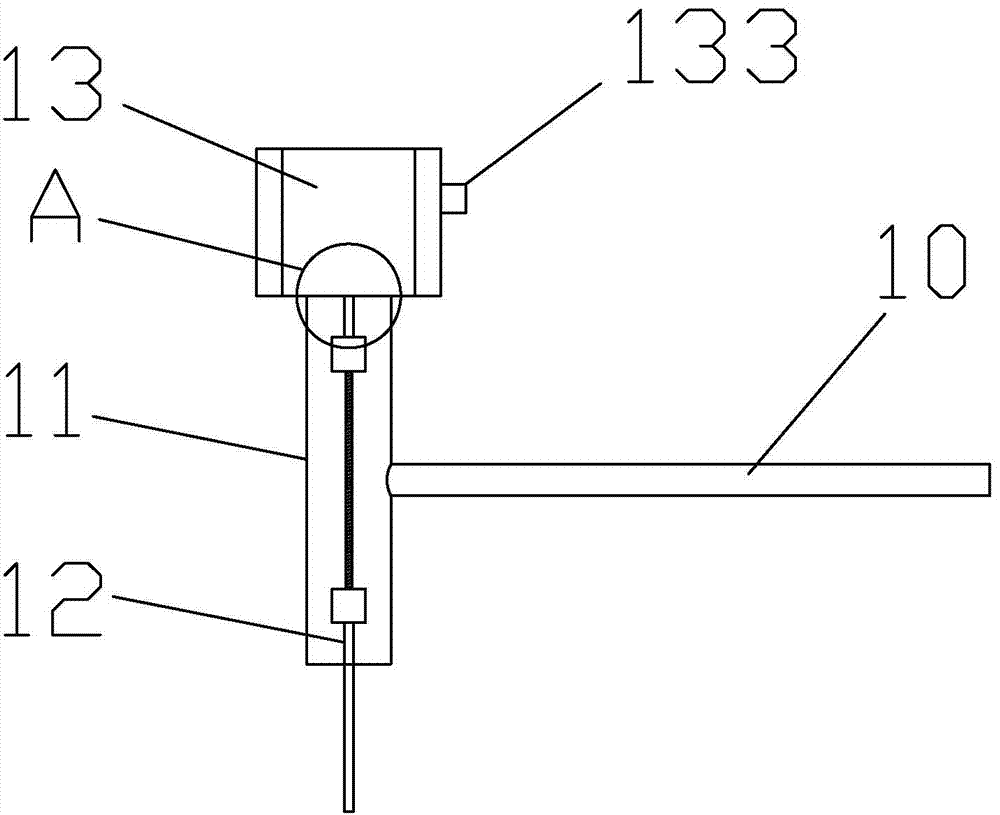

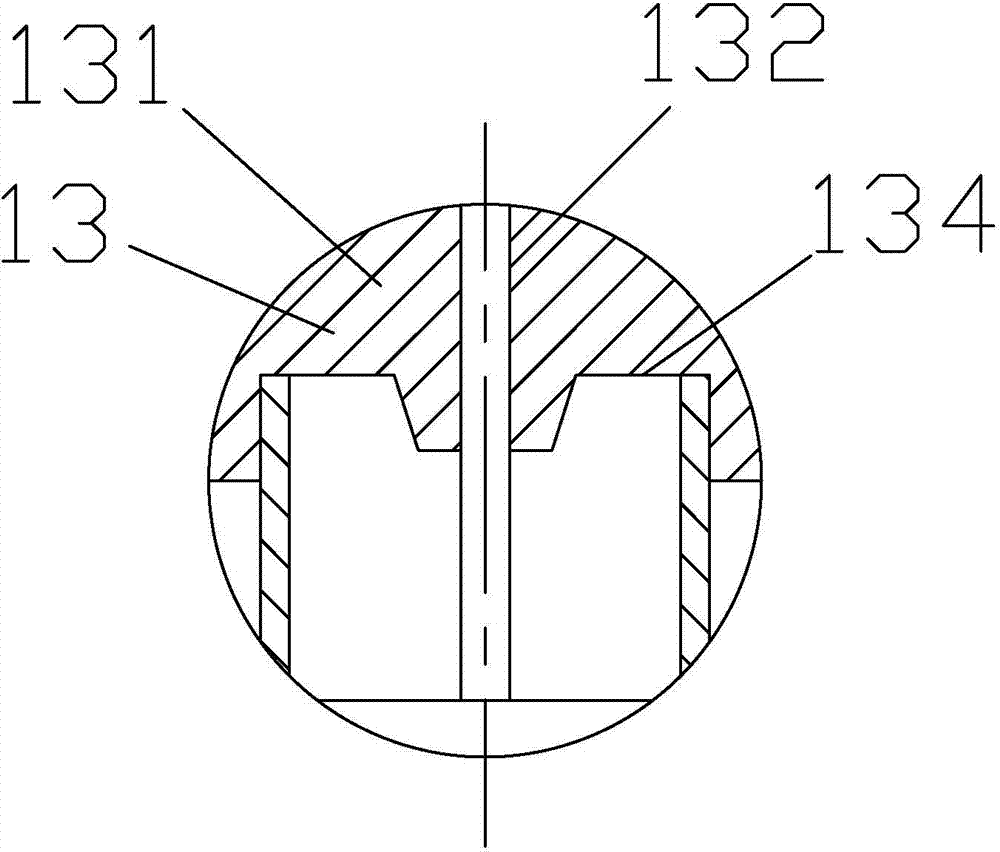

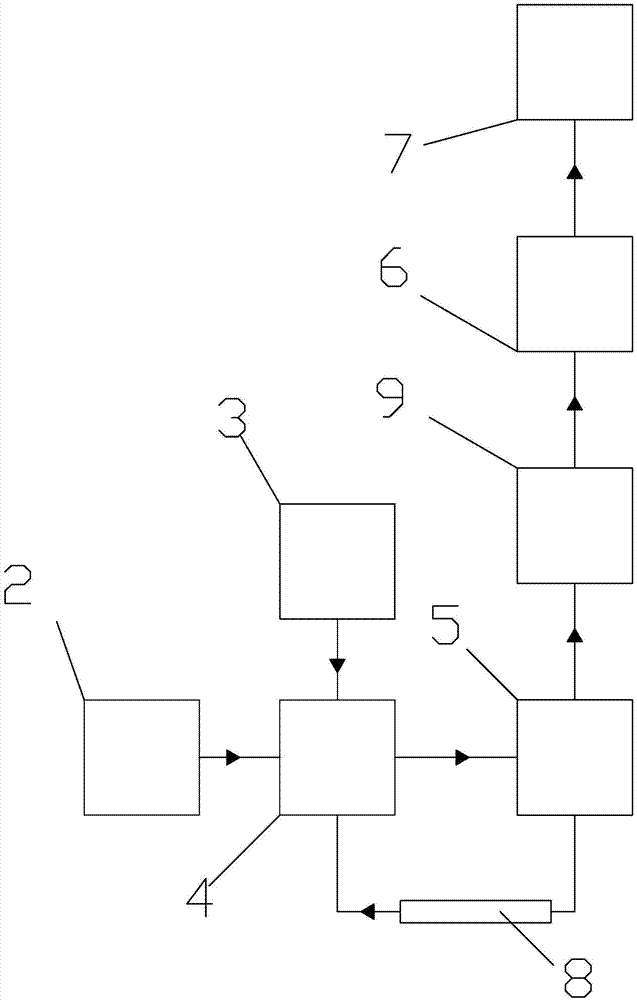

[0027] refer to Figure 1 to Figure 10 , a fully automated production line for halogen lamps provided by the present invention, including a filament spot welding unit 2 for welding the filament, molybdenum sheet and lamp pin, a connecting unit 3 for connecting the glass tube 11 with the exhaust pipe 10, connecting the filament The assembly 12 is put into the threading unit 4 in the glass tube 11, the clamping unit 5 that clamps and seals the lamp pins at both ends of the glass tube 11, and the test unit 9 for carrying out the withstand voltage test on the bulb, and the clamped exhaust pipe The exhaust unit 6 that is filled with halogen gas and the aging unit 7 that waits for the bulb to age, the output end of the filament spot welding unit 2 and the output end of the connection unit 3 are connected to the threading unit 4 at the same time, and the threading unit 4 A plug conveying mechanism 8 for conveying the plug 13 is also connected to the top, the input end of the plug con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com