Electric machine vise with dual movable jaws

A technology of movable jaws and flat-nose pliers, which is applied in vices, manufacturing tools, etc., can solve the problems of uneven force on workpieces, time-consuming and labor-intensive labor of flat-nose pliers, and waste, so as to expand the processing range, reduce manpower loss, and reduce time. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

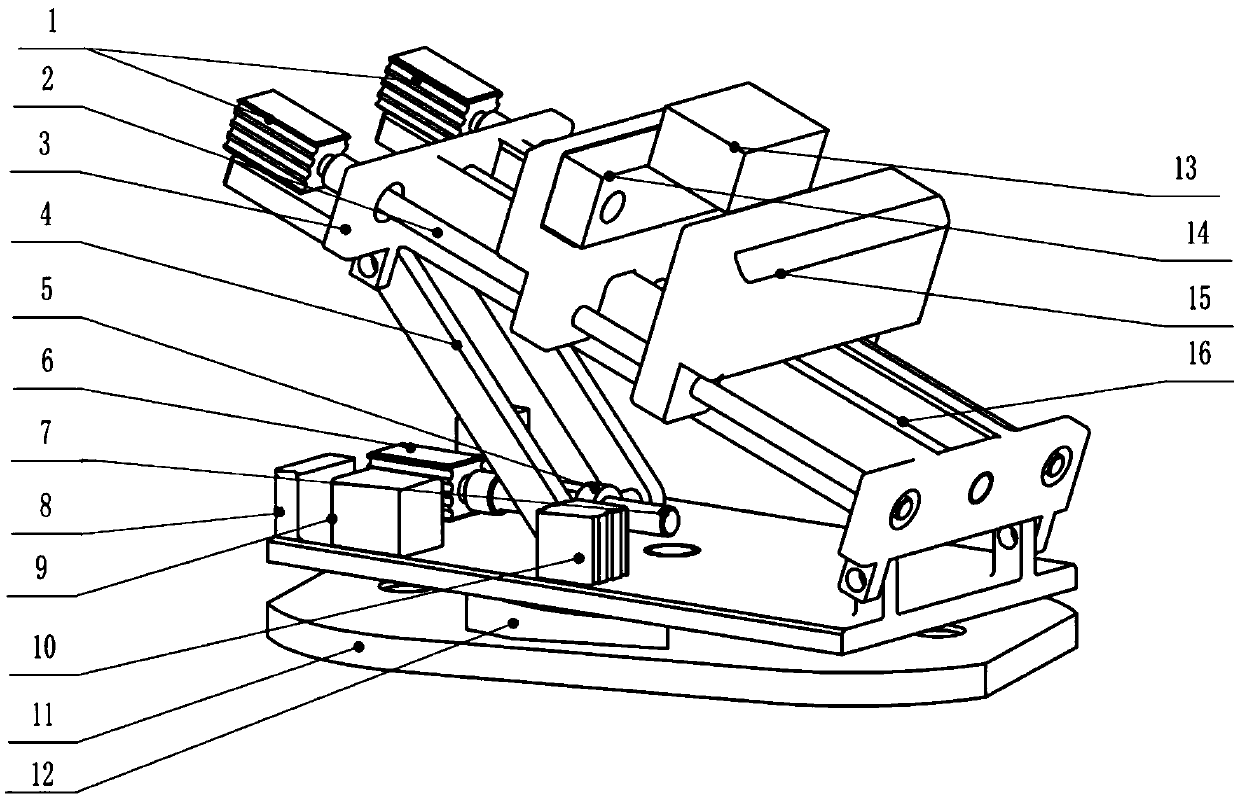

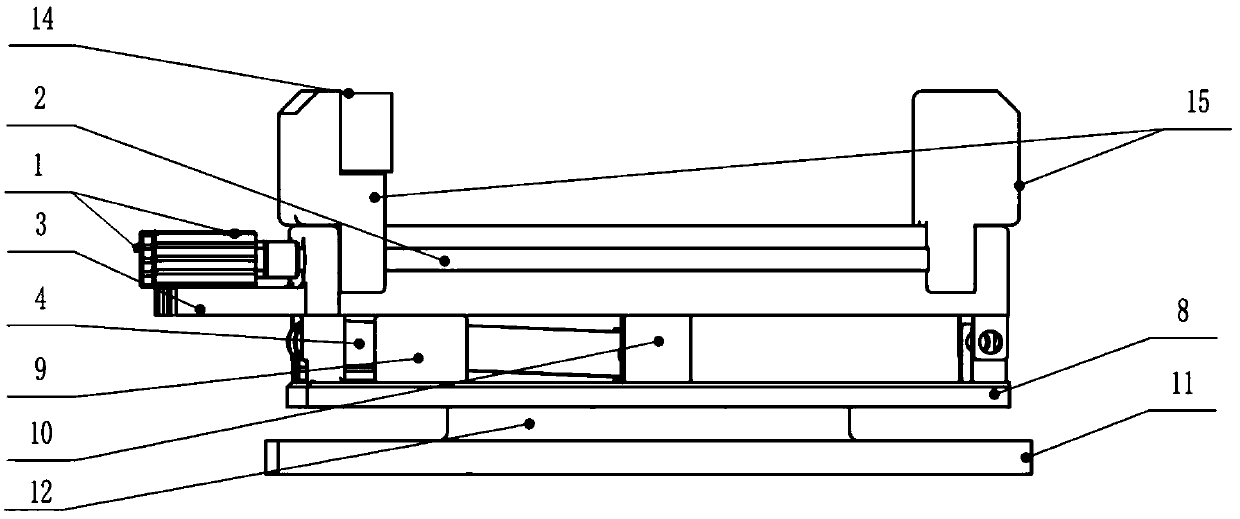

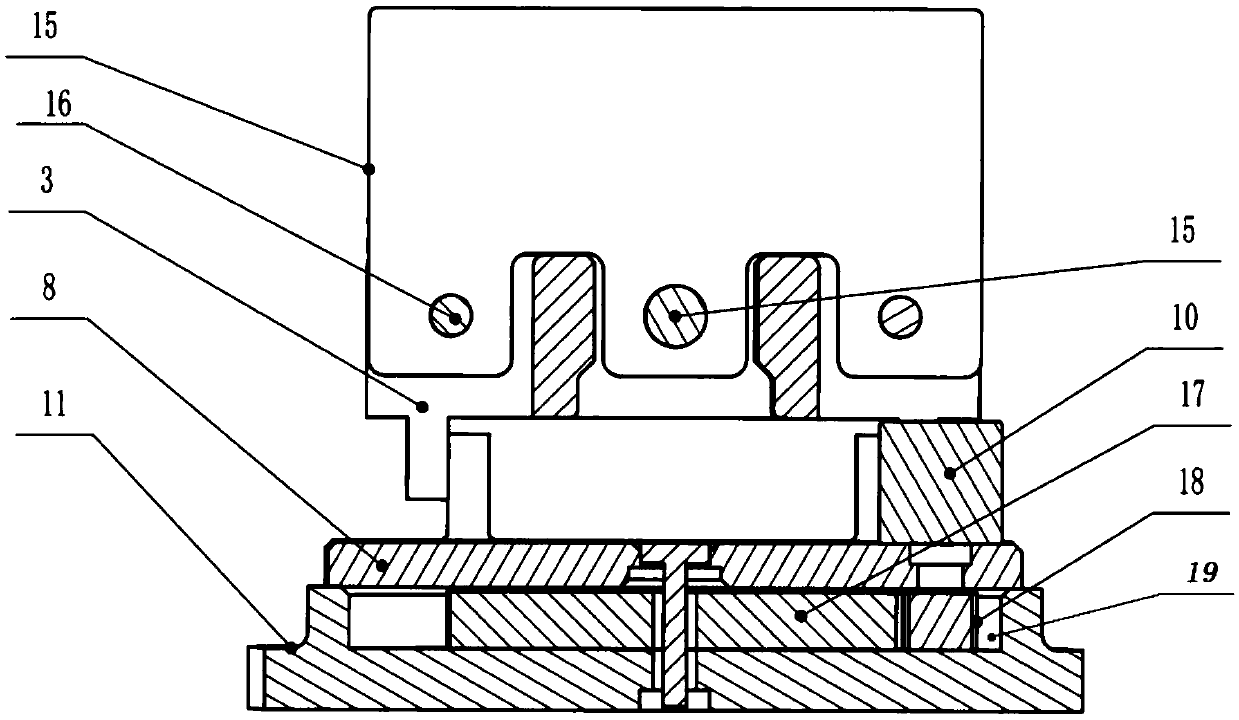

[0018] attached Figure 1-3 The present invention relates to an electric double movable jaw vise, comprising a rotating base, a clamping mechanism arranged at one end of the rotating base and connected by a hinge, an angle adjustment structure arranged at the other end of the rotating base for adjusting the angle of the clamping mechanism, Control the control box 9 of the above mechanism; the clamping mechanism includes a clamp base 3, two movable clamp bodies 15 that are slidably arranged on the clamp base 3 and placed symmetrically; the two sides of the clamp base 3 are respectively provided with 3 Drive screw rods 2 placed on the long side, the screw threads on both sides of each drive screw rod 2 are in opposite directions, and one end of the drive screw rod 2 is connected to the drive motor 1, and the two sides of the two movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com