Super-long attachment construction method of tower crane

A technology of tower crane and construction method, applied in cranes and other directions, can solve the problems of waste of resources, adverse effects of frame construction, long attachment distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Tower cranes are referred to as tower cranes for short, also known as tower cranes. It is mainly used for vertical and horizontal transportation of materials and installation of building components in house construction. It consists of three parts: metal structure, working mechanism and electrical system. The metal structure includes the tower body, the boom and the base, etc. The working mechanism has four parts: lifting, luffing, slewing and walking. The electrical system includes motors, controllers, power distribution cabinets, connecting lines, signals and lighting devices, etc.

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

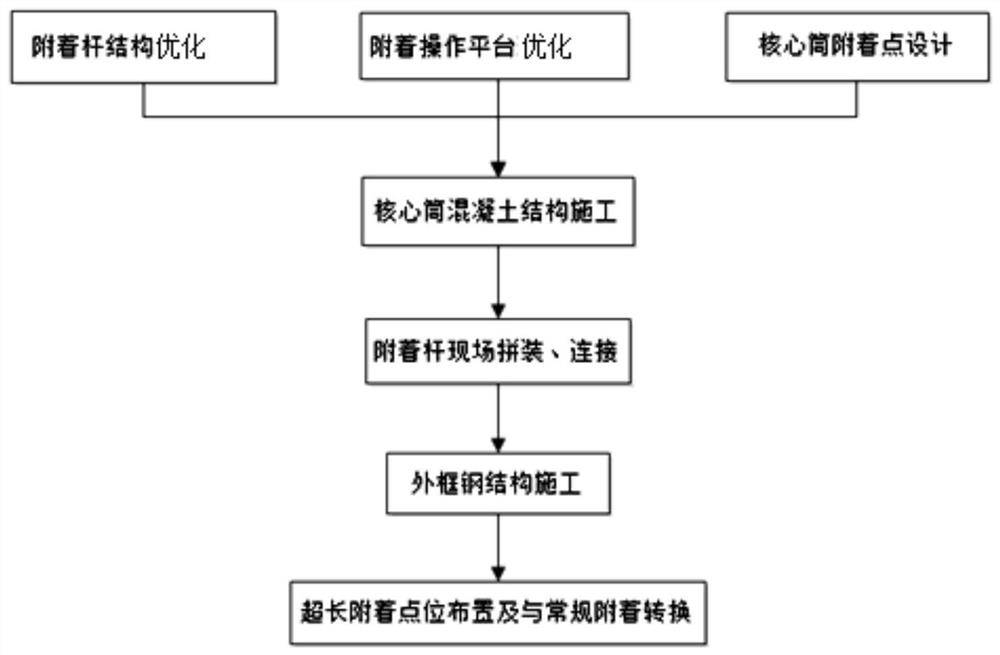

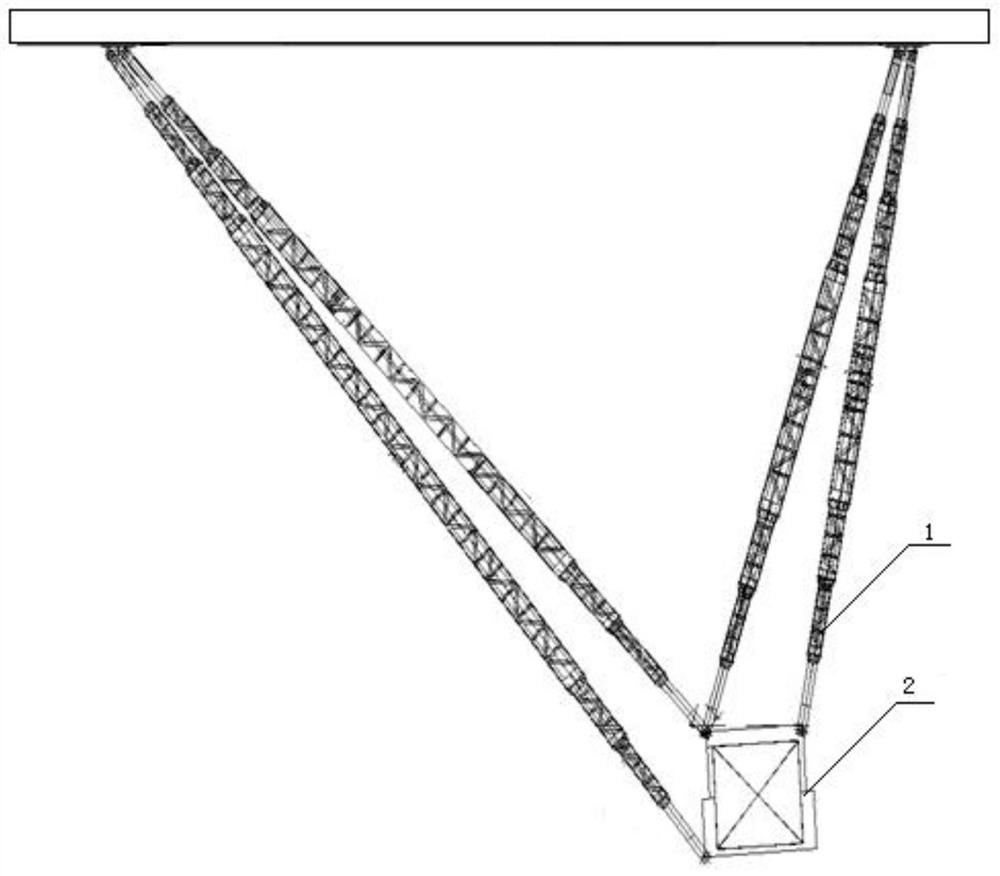

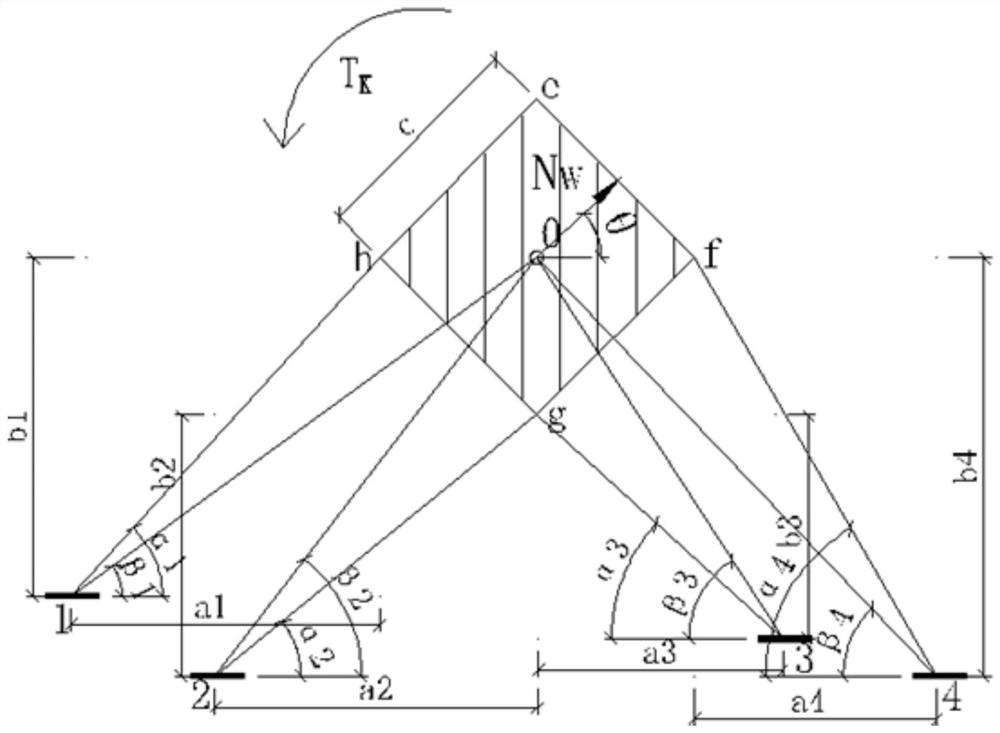

[0031] The invention provides a super-long attachment construction method of a tower c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com