Cement brick loader

A cement brick and loader technology, applied in cranes, transportation and packaging, trolley cranes, etc., can solve the problems of manpower waste, low labor efficiency, high labor intensity, etc., and achieve the effect of light structure and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

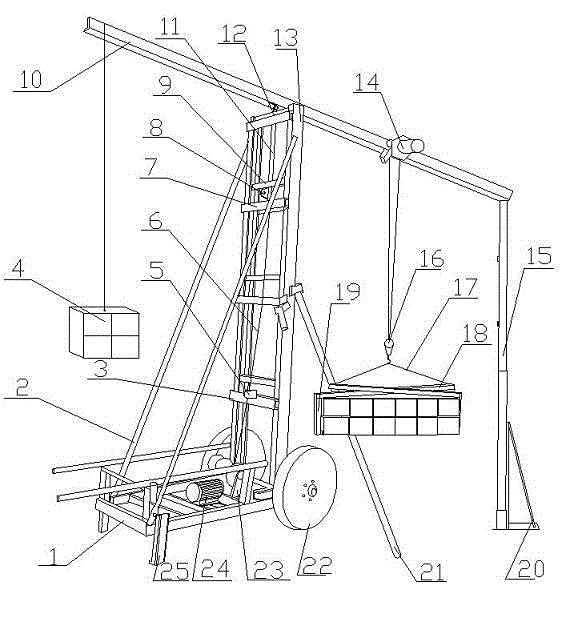

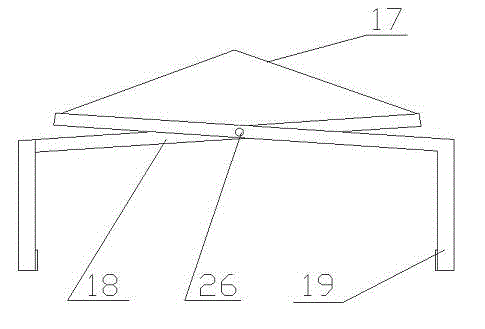

[0020] Such as figure 1 Shown, is the three-dimensional structure schematic diagram of cement brick loader of the present invention, comprises triangular support, hoisting mechanism, hanging rod, gourd hanger 14 and cement brick fixture, wherein:

[0021] Triangular support comprises vertical support 12, transverse support 1 and two diagonal braces 2, and the lower end of vertical support 12 and an end of transverse support 1 are vertically fixedly connected to each other, and vertical support 12 comprises two vertical rods 13 and several root and vertical Bar 13 interval vertically connected cross bar 3, and vertical bar 13 is channel steel; Described lifting mechanism comprises positioning cross bar 7, push rod 11, block pulley, winch 23 and winch wire rope 6, wherein: described positioning cross bar 7 is The channel steel is arranged between two vertical bars 13 and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com