Method for live replacement of +/-500kV DC line strain tower insulator string

A technology of insulator strings and live replacement, which is applied in the direction of overhead lines/cable equipment, etc., can solve problems such as difficult to ensure safe and stable operation of lines, and achieve the effects of reducing manpower loss, high work efficiency, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

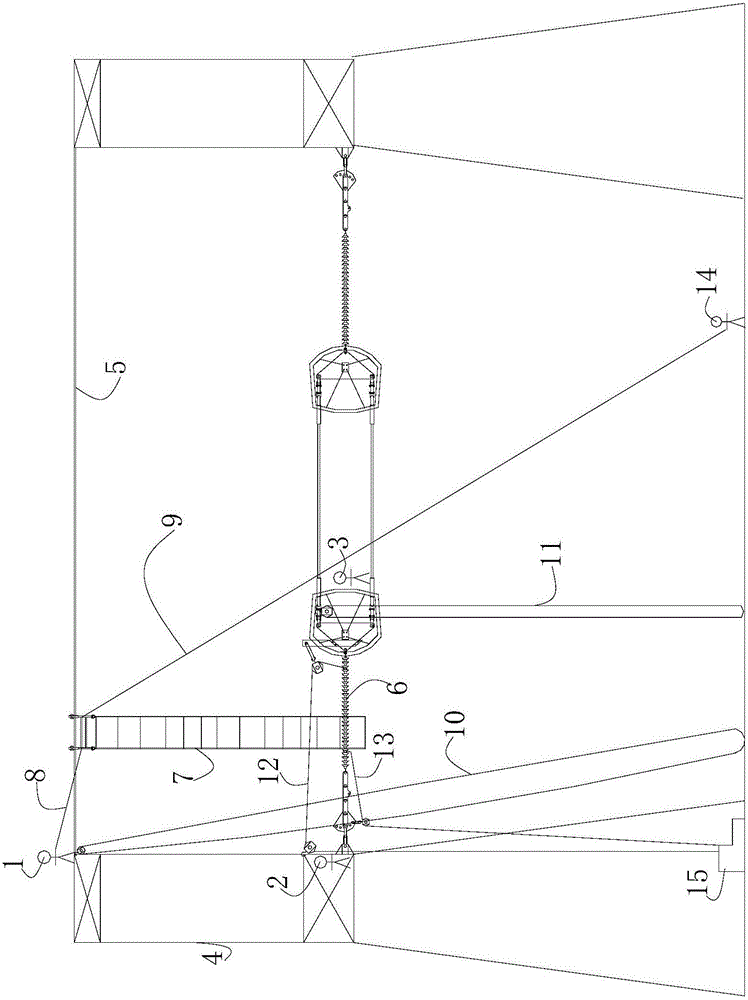

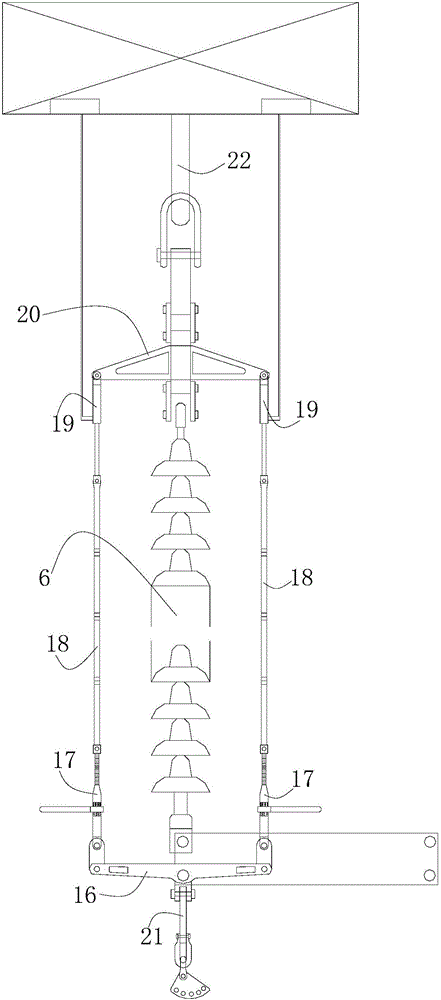

[0026] The method of replacing the ±500kV DC line strain tower insulator string 6 with power on, such as Figure 1-2 shown, including the following steps:

[0027] 1) Equipment preparation: prepare the first transmission rope 10, the second transmission rope 11, safety belt, overhead ground wire block 23, insulating ladder 7, first insulating flexible rope 8, second insulating flexible rope 9, tower head end Special fixture 16, hydraulic screw mandrel 17, lead end special fixture 20, labor-saving screw mandrel 19, insulating suspender 18, the first traction rope 12, the first turning tackle, the second turning tackle, the second traction rope 13, the first pulling rope Three steering blocks and motorized winch 15; wherein the first transmission rope 10, the second transmission rope 11, the first traction rope 12, and the second traction rope 13 are all insulating materials;

[0028] 2) The first electrician 1, the second electrician 2, and the third electrician 3 go up the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com