Efficient smoke white eliminating method and device

A flue gas and whitening technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of high site layout requirements, increased power consumption of circulating pumps, and excessive flue gas temperature, reducing investment and improving The effect of safe and stable operation reliability and power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below with reference to the drawings and embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

[0015] Examples.

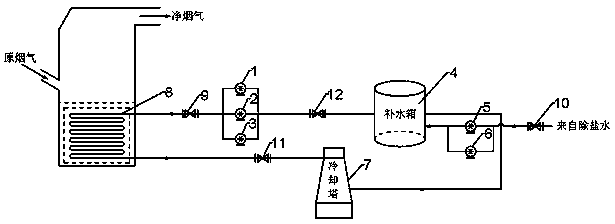

[0016] See figure 1 In this embodiment, the high-efficiency flue gas whitening method is as follows: the condensing heat exchanger 8 is arranged in the slurry tank of the desulfurization system of the coal-fired power plant, the temperature of the slurry in the slurry tank of the desulfurization system is reduced through the partition wall heat exchange, and then the desulphurization slurry spray The circulation of the shower system reduces the temperature of the flue gas at the outlet of the desulfurization tower and achieves the effect of net flue gas condensation, dehumidification and whitening.

[0017] The flue gas whitening system includes a slurry cooling system, a cooling water circulation system, a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com