Novel integration technique for improving recovery ratio of thick oil with high thickness and low yield

A recovery factor and heavy oil technology, applied in the fields of fluid extraction, earthwork drilling, drilling composition, etc., can solve the problems of lower crude oil quality, consumption of thin oil resources, hindering industrial development, etc., and achieve high applicability, Enhanced oil recovery and the effect of technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

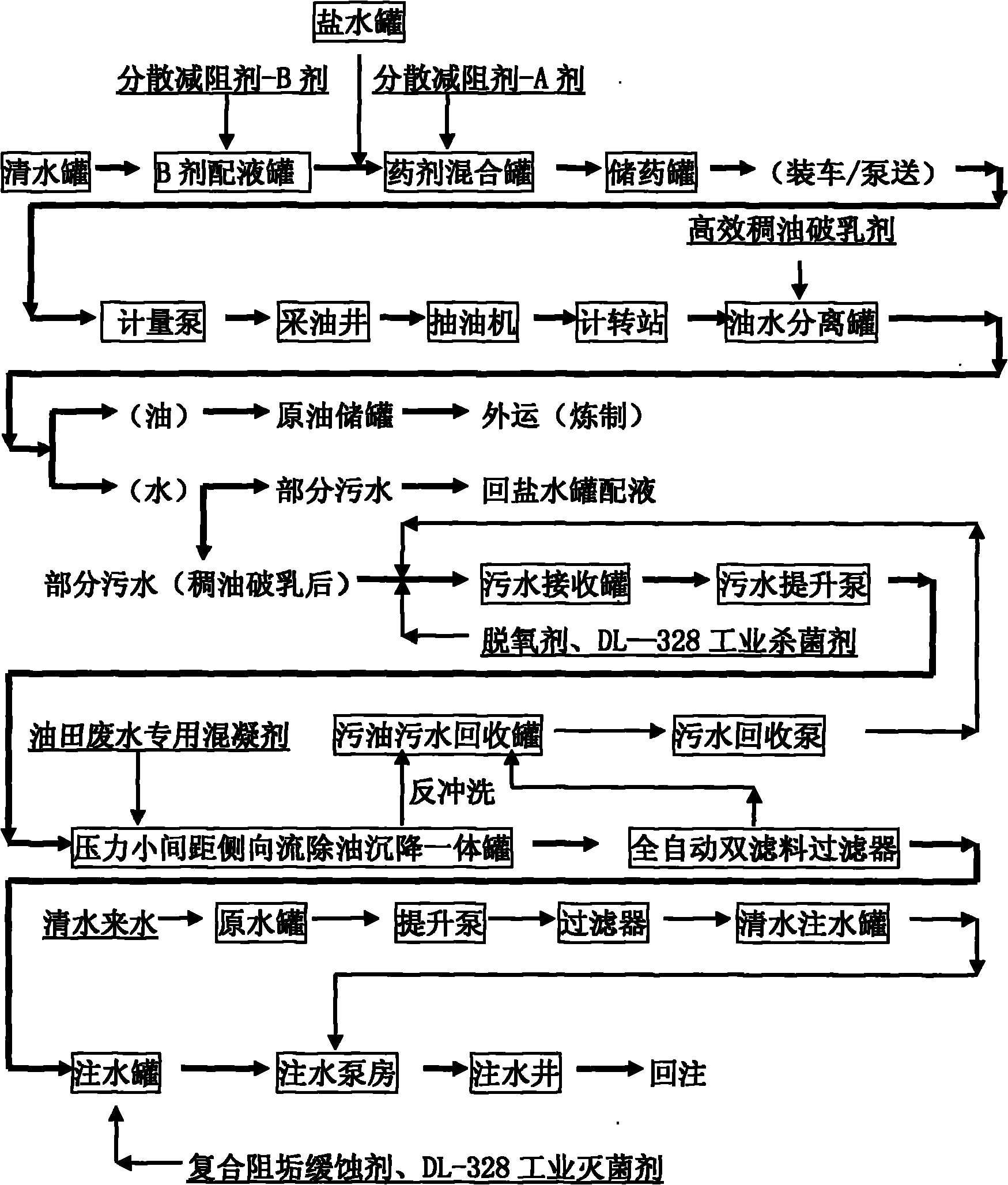

Method used

Image

Examples

Embodiment

[0027] Test point: 40 oil wells in an oilfield in Xinjiang; the average viscosity of the original oil sample at 50°C is 90000mPa·s.

[0028] A group of control: using conventional thinning and viscosity reduction technology, daily dosing of 16 tons of thin oil, 37 tons of mixed liquid production, 21 tons of formation liquid production, including 18 tons of oil production, 6 tons of water production, and a viscosity of 900mPa at the wellhead production fluid at 50°C s;

[0029] Using self-made thick oil dispersion drag reducer, injecting 1% of agent A and 0.125% of agent B in aqueous solution, the daily injection volume is 6 tons, the mixed liquid production is 37 tons, and the formation liquid production is 31 tons, of which oil production is 22.86 tons and formation water production is 8.14 tons, the viscosity of the fluid produced at the wellhead is 150mPa·s at 50°C, the viscosity reduction rate is greater than 99%, and the daily saving of thin oil is 16 tons.

[0030] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com