Horizontal well completion and sand control water controlling screen pipe

A technology for horizontal wells and water screens, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve problems such as erosion and complex structures during use, and achieve the goal of increasing recovery and reducing water breakthrough time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

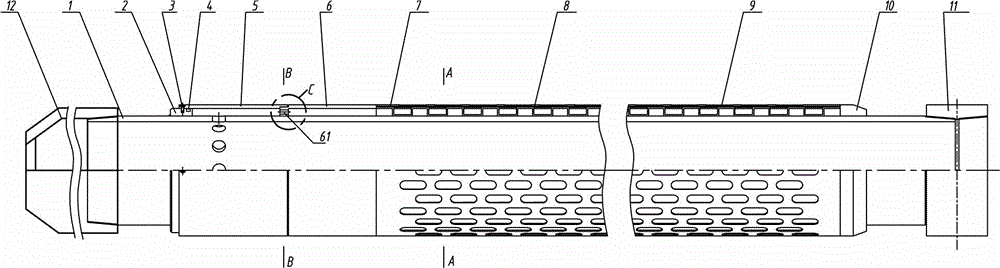

[0031] Such as figure 1 Among them, a water control screen for horizontal well completion and sand control, including a base pipe 1, the base pipe 1 in this example can be multi-section or single-section, each section is connected by a coupling 11, and the first section The front end of the base pipe 1 of the section is provided with a plugging head 12 .

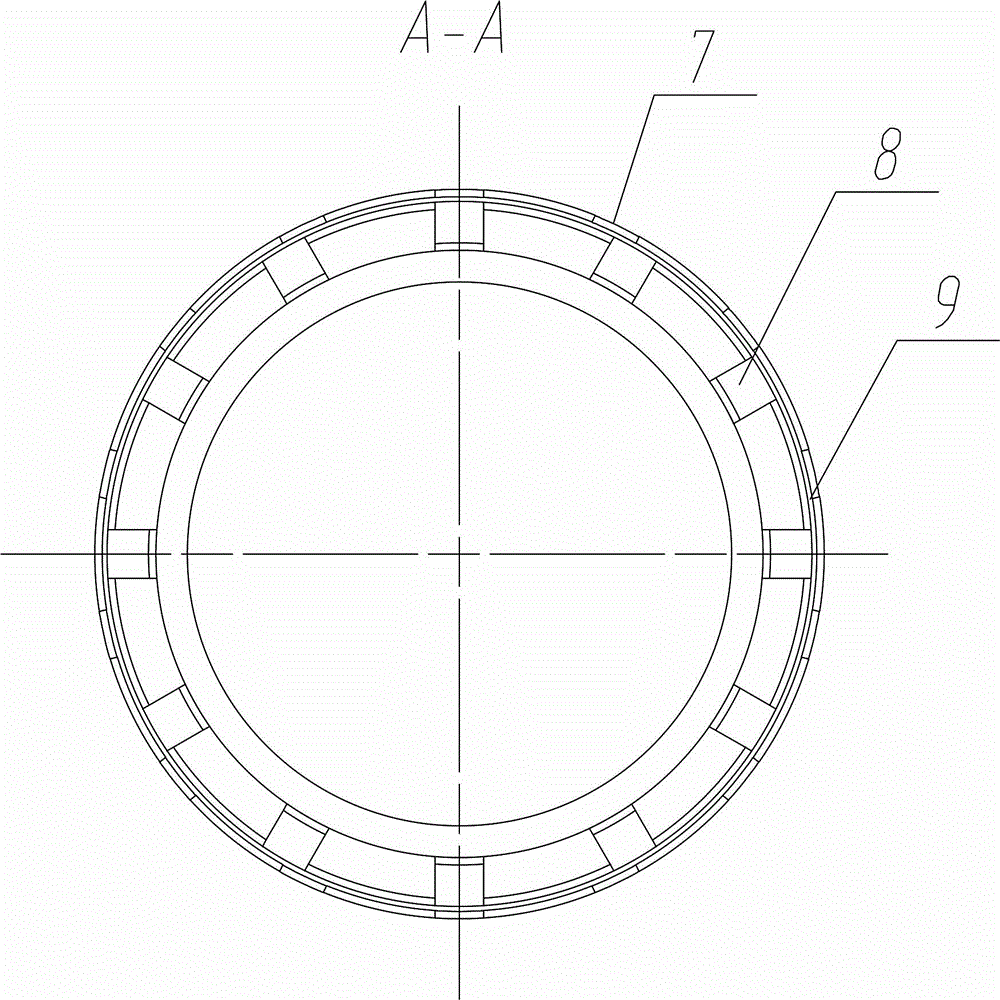

[0032] Taking a single section as an example, the base pipe 1 is covered with a screen 7 and a restrictor 6. The restrictor 6 is cylindrical, and a joint is provided between the inner wall of the restrictor 6 and the outer wall of the base pipe 1. The flow device; the screen 7 is also cylindrical, and the screen 7 is provided with a screen hole, and the screen 7 is made of stainless steel.

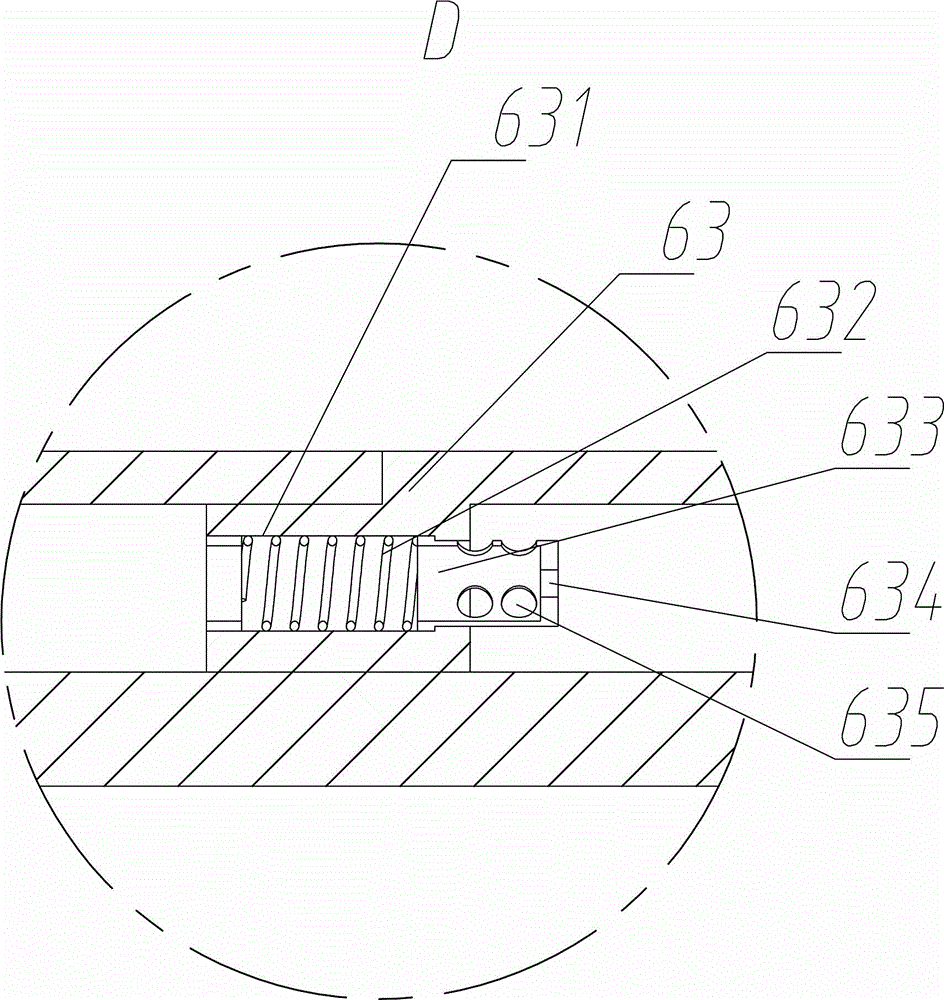

[0033] One end of the restrictor 6 is connected to the base pipe 1 through the first support plate 2, the other end of the restrictor 6 is connected to one end of the screen 7, and the other end of the screen 7 is connected to the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com