Composite oil displacing agent

An oil and compound technology, applied in the field of oil displacement agent, can solve the problem of high cost and achieve the effects of cost reduction, viscosity protection and damage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

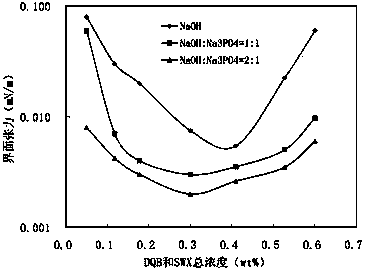

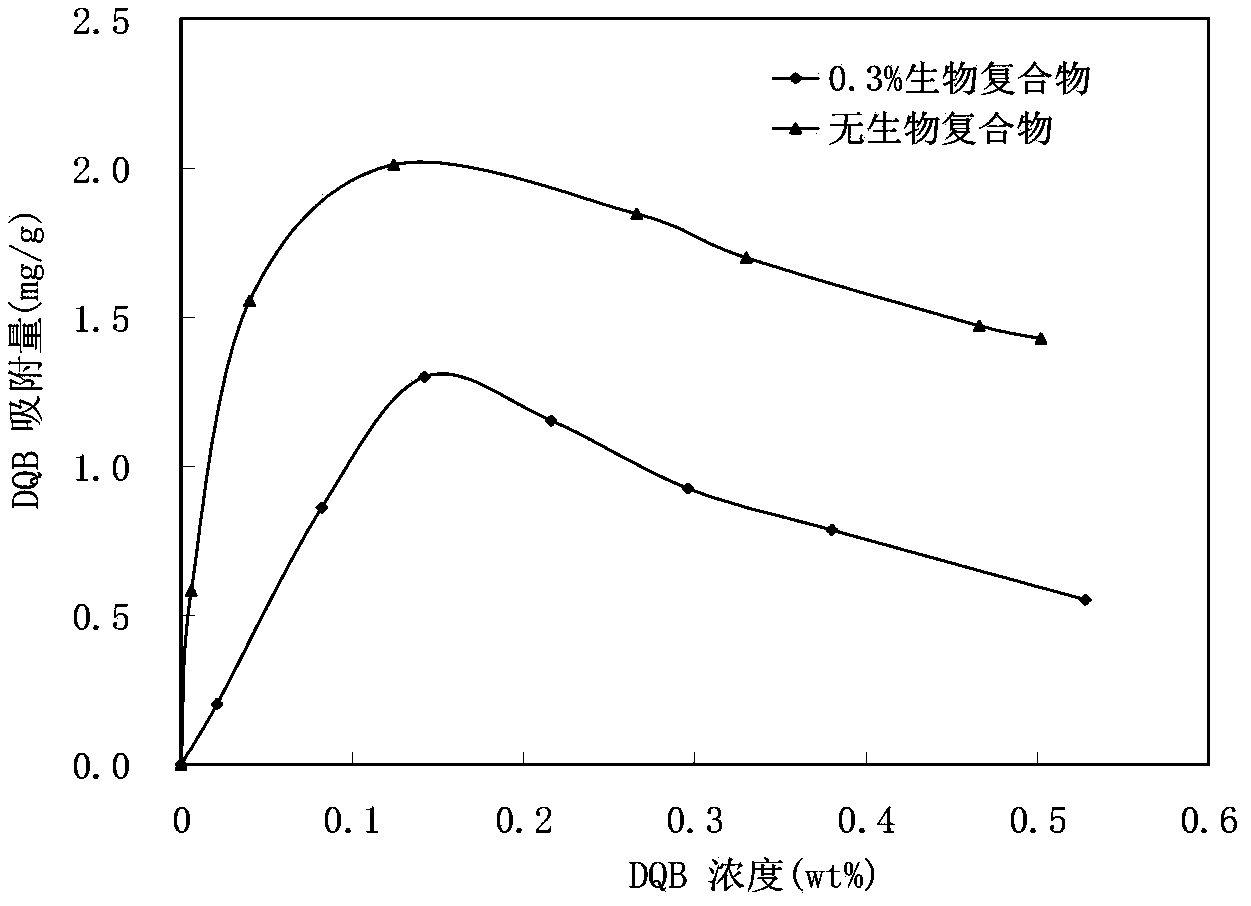

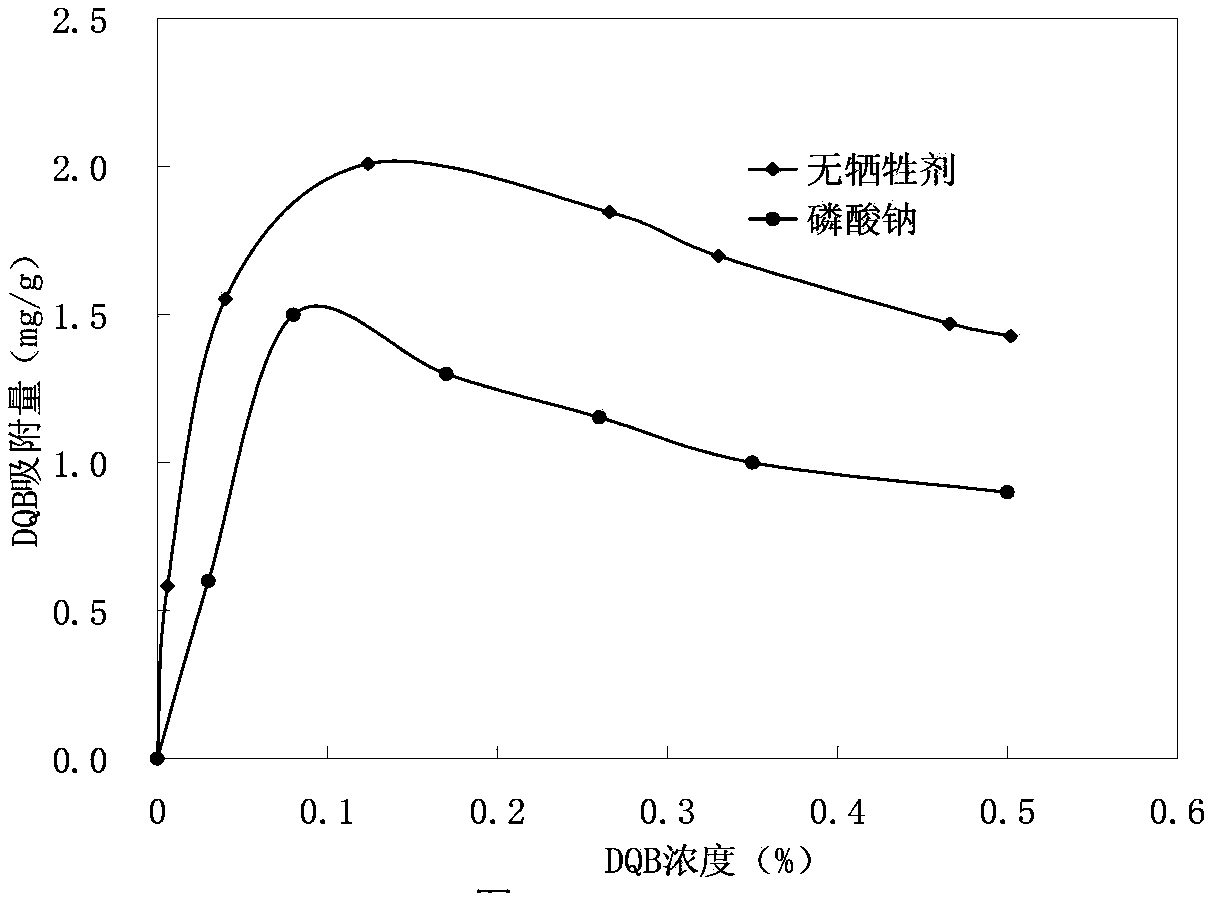

[0083] Compound flooding oil displacement agent preparation, first add 0.3 part of sodium alkylbenzene sulfonate (DQB) + 0.3 part of biological compound + 0.8 part of NaOH + 0.4 part of Na 3 PO 4 +0.15 parts of polymer (KY-2) made up to 100 parts with injection water. After stirring evenly, the adsorption capacity measurement results: figure 1 , after adding biological compound (SWX) to the oil displacement agent, the adsorption amount of surfactant (DQB) is reduced by more than 30%; figure 2 , After sodium phosphate was added to the oil displacement agent, the adsorption amount of surfactant (DQB) decreased by about 20%, and the adsorption amount was 1.3mg / g oil sand, which decreased by 30%. Oil displacement agent and crude oil interfacial tension measurement see image 3 and Figure 4 , the interfacial tension of biological complex (SWX) is significantly higher than that of surfactant (DQB), indicating that the former has a certain interface activity; 10 -3 Below the o...

example 2

[0088] Compound flooding oil displacement agent preparation, first add 0.1 part of sodium alkylbenzene sulfonate (DQB) + 0.2 part of biological compound + 0.6 part of NaOH + 0.3 part of Na 3 PO 4 +0.1 part of polymer (KY-2) is replenished to 100 parts with injection water, after stirring evenly. After adding biological compound (SWX) and sodium phosphate to the oil displacement agent, the adsorption amount of surfactant (DQB) decreased by about 50%; the interfacial tension between the oil displacement agent and crude oil was 5.2×10 -3 mN / m. The viscosity of the oil displacement agent system is 26.4mPa.s. According to the results of the oil displacement experiment, the oil recovery rate is increased by 18.1%.

example 3

[0090] Composite oil displacement agent preparation, first add 0.4 part of sodium alkylbenzene sulfonate (DQB) + 0.4 part of biological compound + 1.0 part of NaOH + 0.4 part of Na 3 PO 4 + 0.15 parts of polymer (KY-2) was added to 100 parts with injected water, after stirring evenly. After adding biological compound (SWX) and sodium phosphate to the oil displacement agent, the adsorption amount of surfactant (DQB) decreased by about 35%; the interfacial tension between the oil displacement agent and crude oil was 4.5×10 -3 mN / m. The viscosity of the oil displacement agent system is 32.1mPa.s. According to the results of the oil displacement experiment, the oil recovery rate is increased by 21.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com