Metal organic framework material as well as preparation method and application thereof

A metal-organic framework and coordination technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides a method for preparing a metal-organic framework material described in the above technical solution, comprising the following steps:

[0045] (1) Mix copper tetrafluoroborate and hexafluoroammonium salt in water to obtain solution A; the hexafluoroammonium salt is ammonium hexafluorosilicate or ammonium hexafluorogermanate; mix bipyridylsulfur and methanol to obtain solution B;

[0046] (2) Add the solution A to the solution B dropwise, and let stand to obtain the metal organic framework material.

[0047] The present invention mixes copper tetrafluoroborate and hexafluoroammonium salt in water to obtain solution A; the hexafluoroammonium salt is ammonium hexafluorosilicate or ammonium hexafluorogermanate. In the present invention, when the metal organic framework material is [Cu(dps) 2 (SiF 6 )]·6H 2 O, the present invention mixes copper tetrafluoroborate and ammonium hexafluorosilicate in water, the molar ratio of copper tetrafluorob...

Embodiment 1

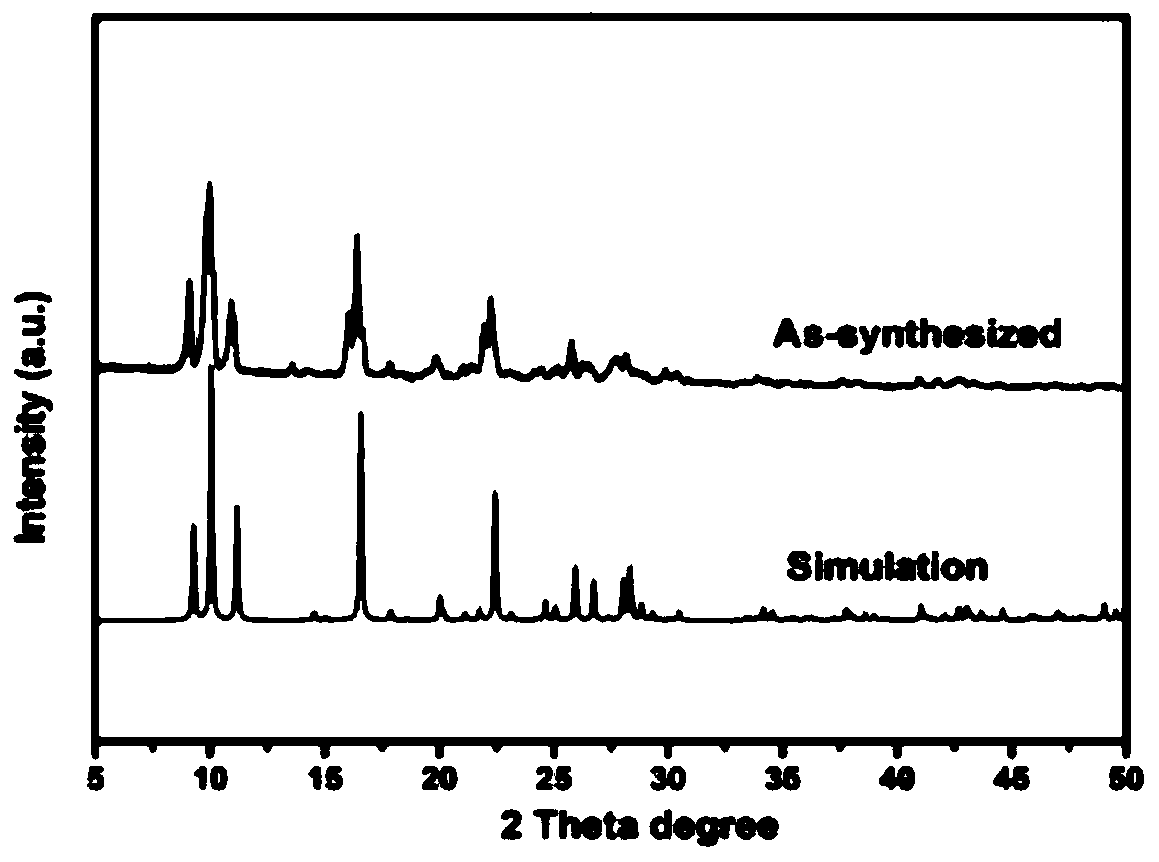

[0065] [Cu(dps) 2 (SiF 6 )].6H 2 o

[0066] Copper tetrafluoroborate Cu(BF 4 ) 2 with ammonium hexafluorosilicate (NH 4 ) 2 SiF 6 According to the molar ratio of 1:1, it was dissolved in 5 mL of deionized water, wherein the concentration of ammonium hexafluorosilicate was 0.0572 mol / L, and stirred at room temperature for 10 min to obtain solution A. Dissolve bipyridylsulfur in 5mL methanol to form solution B, the concentration of bipyridylsulfur is 0.0572mol / L; slowly add solution A to solution B at a rate of 1 mL / min, and let stand at room temperature for 24h. The resulting mixture was filtered with suction, washed with a large amount of methanol, and dried overnight in an oven at 25° C. to obtain 0.058 g of the product with a yield of 29.4%.

Embodiment 2

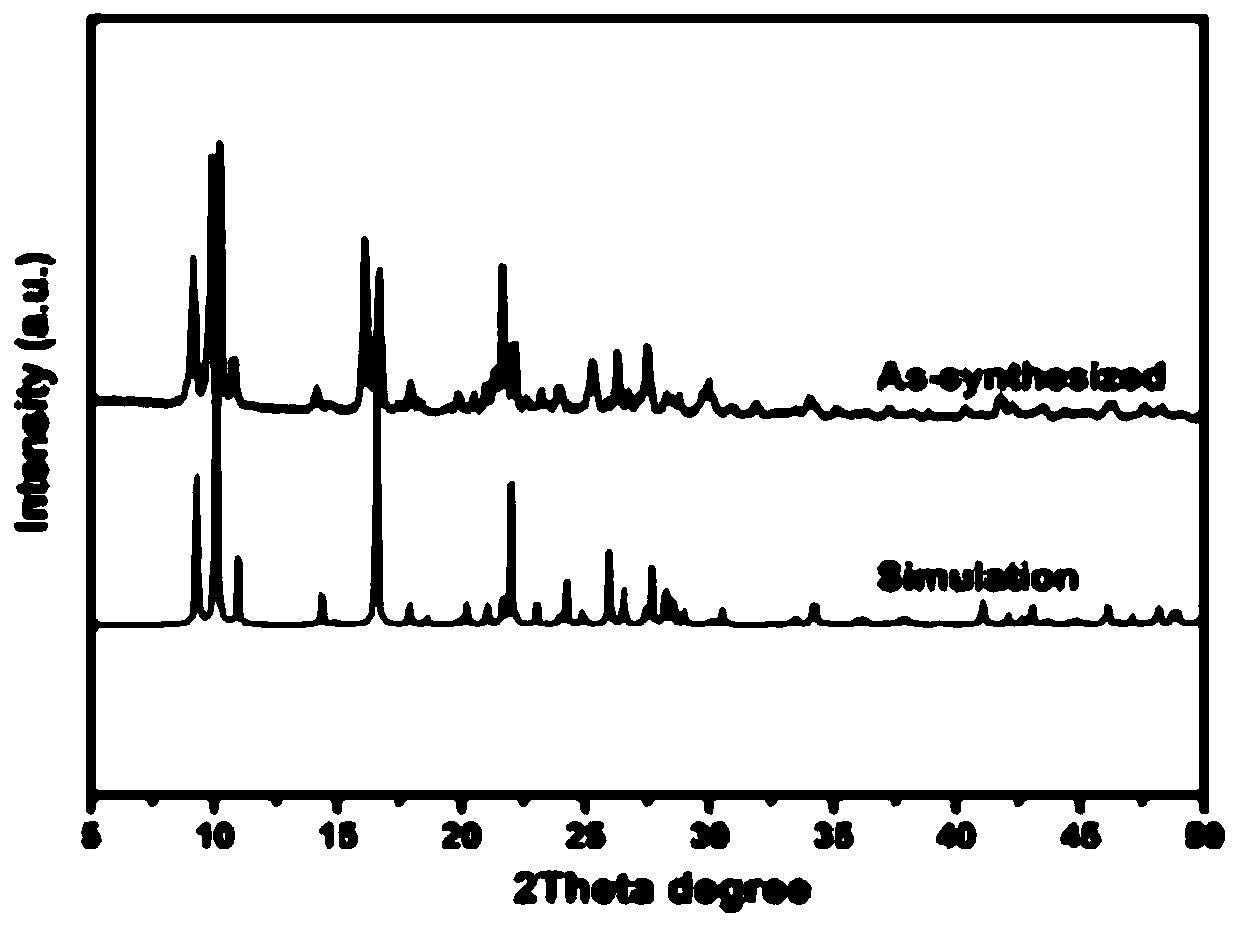

[0068] [Cu(dps) 2 (SiF 6 )].6H 2 o

[0069] Copper tetrafluoroborate Cu(BF 4 ) 2 with ammonium hexafluorosilicate (NH 4 ) 2 SiF 6 Dissolve in 50mL deionized water according to the molar ratio of 1:2, wherein the concentration of ammonium hexafluorosilicate is 1.144mol / L, and stir at room temperature for 10min to obtain solution A. Dissolve bipyridylsulfur in 50mL methanol to form solution B, the concentration of bipyridylsulfur is 1.144mol / L; slowly add solution A to solution B at a rate of 2mL / min, and let stand at room temperature for 24h. The resulting mixture was filtered with suction, washed with a large amount of methanol, and dried overnight in an oven at 25° C. to obtain 0.62 g of the product with a yield of 31.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com