Preparation method of magnetic nano molecularly imprinted polymer for separating nicotinic pesticide IPP

A magnetic nanoparticle and magnetic nanotechnology, which is applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems that the separation method of the new nicotine pesticide, pichamidin, has not been reported, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Embodiment 1: A method for preparing a magnetic nano-molecularly imprinted polymer for separating the nicotine pesticide pichamidin according to the present embodiment is carried out according to the following steps:

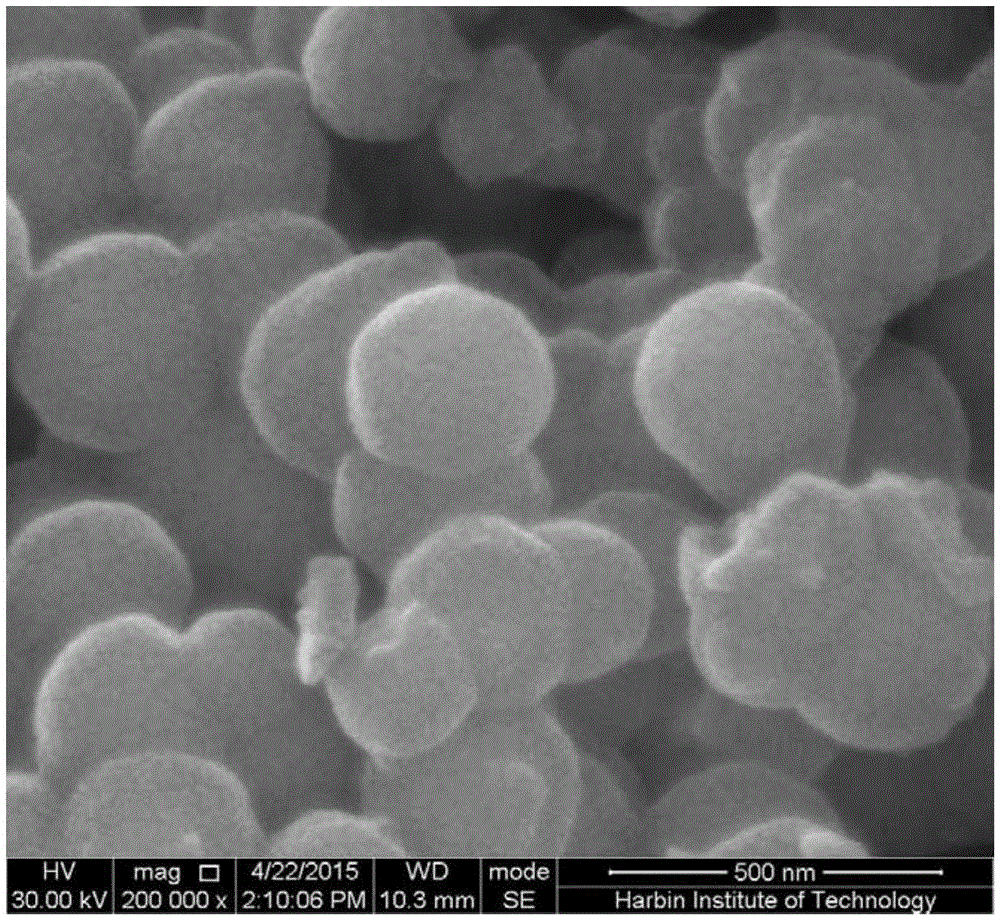

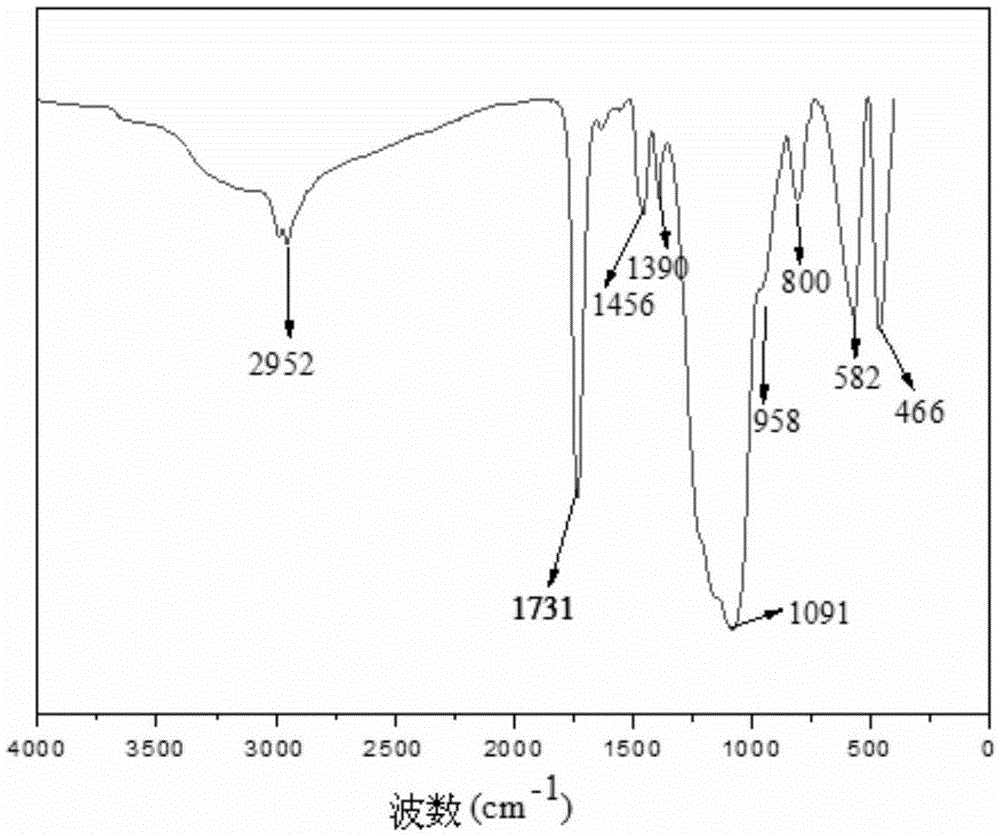

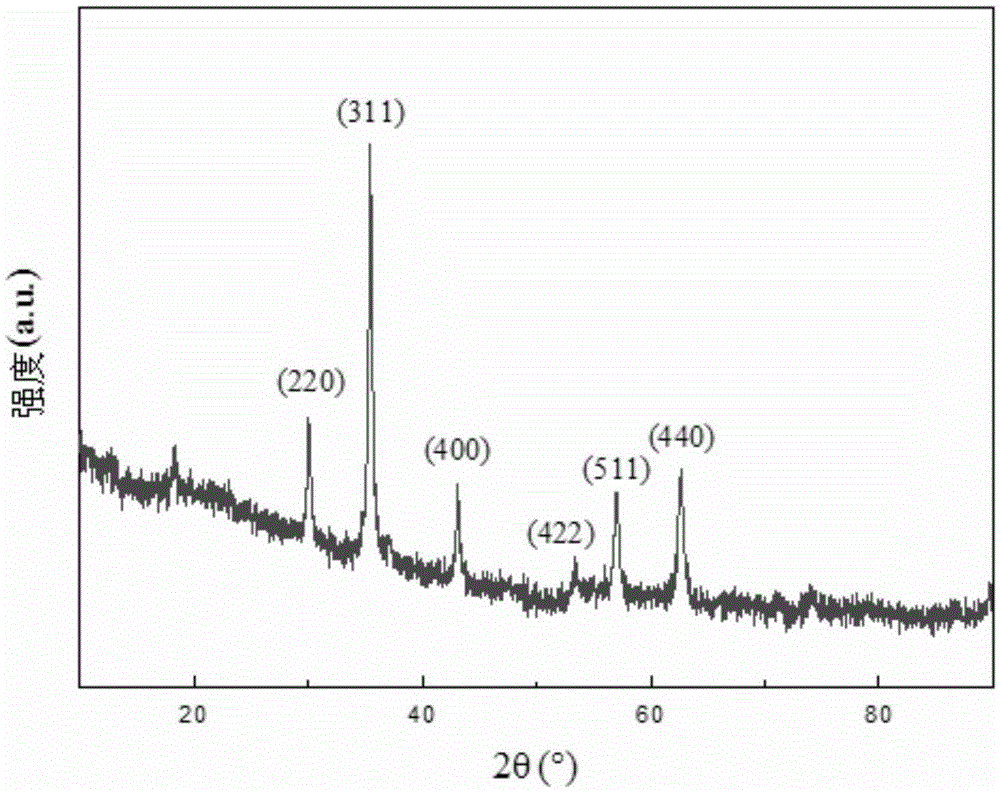

[0031] 1. Preparation of Fe 3 o 4 Magnetic nanoparticles: Dissolve ferric chloride in ethylene glycol, ultrasonically treat until no solid exists, then add anhydrous sodium acetate, stir at a stirring speed of 400r / min~600r / min for 25min~35min, transfer Put it in the reaction kettle, react at a temperature of 180-220°C for 11h-13h, stop the reaction, let it stand for 15min-25min, and then use a neodymium-iron-boron magnet for magnetic separation and sedimentation. After pouring out the upper liquid, the obtained solid The substance is subjected to washing treatment, and then the washed substance is vacuum-dried at a temperature of 40-50°C for 5h-7h to obtain Fe 3 o 4 Magnetic nanoparticles; the washing treatment process is as follows: 1. Wash the solid...

specific Embodiment approach 2

[0044] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the ratio of the mass of ferric chloride described in step one to the volume of ethylene glycol is 13.5g:500mL; The mass ratio of ferric chloride to anhydrous sodium acetate is 13.5:36. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0045] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the Fe obtained in step one described in step two 3 o 4 The ratio of the mass of magnetic nanoparticles to the volume of hydrochloric acid is 0.4g: 15mL; the Fe obtained in step 1 described in step 2 3 o 4 The ratio of the mass of magnetic nanoparticles to the volume of trisodium citrate is 0.4g:15mL. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com