Electrohydraulic control reserving valve and electrohydraulic control system

An electro-hydraulic control system and electro-hydraulic control technology, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problem of small flow rate of reversing valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

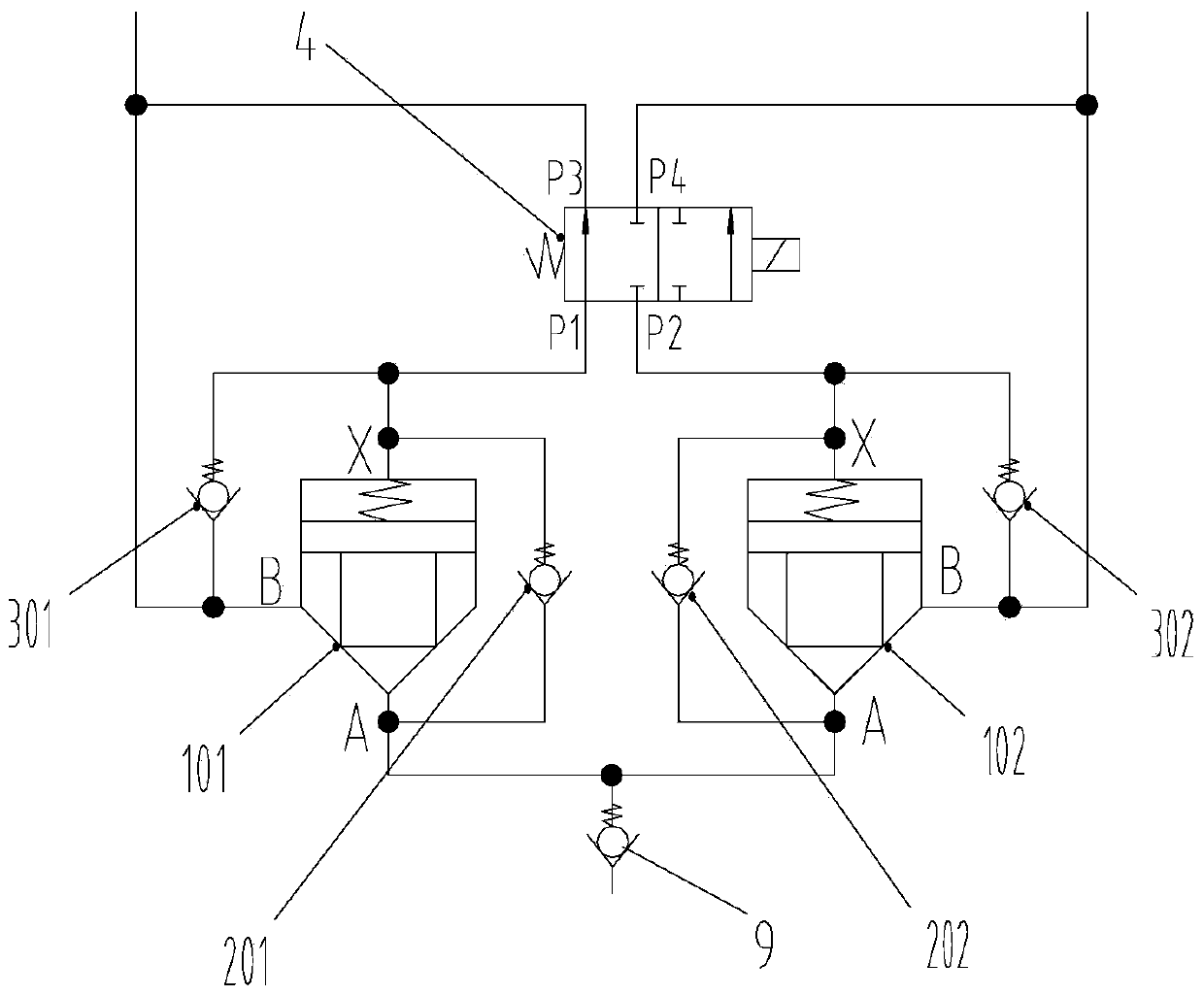

[0025] The embodiment of the present invention provides an electro-hydraulic control reversing valve, such as figure 1 As shown, the electro-hydraulic control reversing valve includes: a first cartridge valve 101, a second cartridge valve 102 and a two-position four-way electromagnetic reversing valve 4, the A port of the first cartridge valve 101 and the second cartridge valve The A port of the valve 102 is connected, the X port of the first cartridge valve 101 is connected with the P1 port of the two-position four-way electromagnetic reversing valve 4, the X port of the second cartridge valve 102 is connected with the two-position four-way electromagnetic reversing valve 4 The P2 port of the two-position four-way electromagnetic reversing valve 4 communicates with the B port of the first cartridge valve 101 and the first actuator (not shown in the figure), and the two-position four-way electromagnetic reversing valve 4 Port P4 of the second cartridge valve 102 communicates w...

Embodiment 2

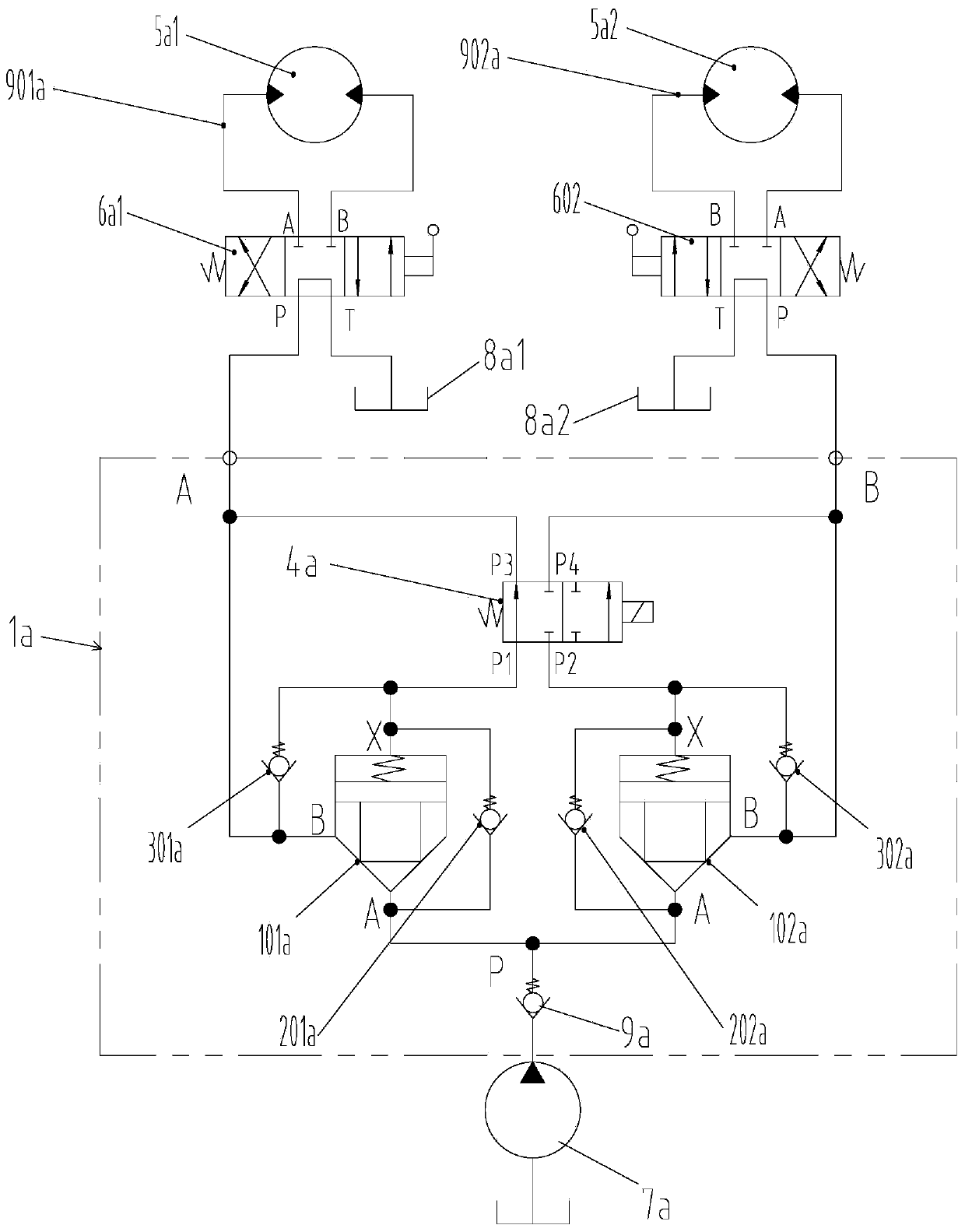

[0032] The embodiment of the present invention provides an electro-hydraulic control system, such as figure 2 As shown, the system includes: the electro-hydraulic control reversing valve 1a provided in Embodiment 1, the hydraulic pump 7a and at least two actuators, the oil outlet of the hydraulic pump 7a communicates with the P port of the electro-hydraulic control reversing valve 1a, The electro-hydraulic control reversing valve 1a includes: a first cartridge valve 101a, a second cartridge valve 102a and a two-position four-way electromagnetic reversing valve 4a, the port A of the first cartridge valve 101a and the port A of the second cartridge valve 102a Port A is connected and communicated with the P port of the electro-hydraulic control reversing valve 1a, the X port of the first cartridge valve 101a is connected with the P1 port of the two-position four-way electromagnetic reversing valve 4a, and the X port of the second cartridge valve 102a It communicates with the P2 ...

Embodiment 3

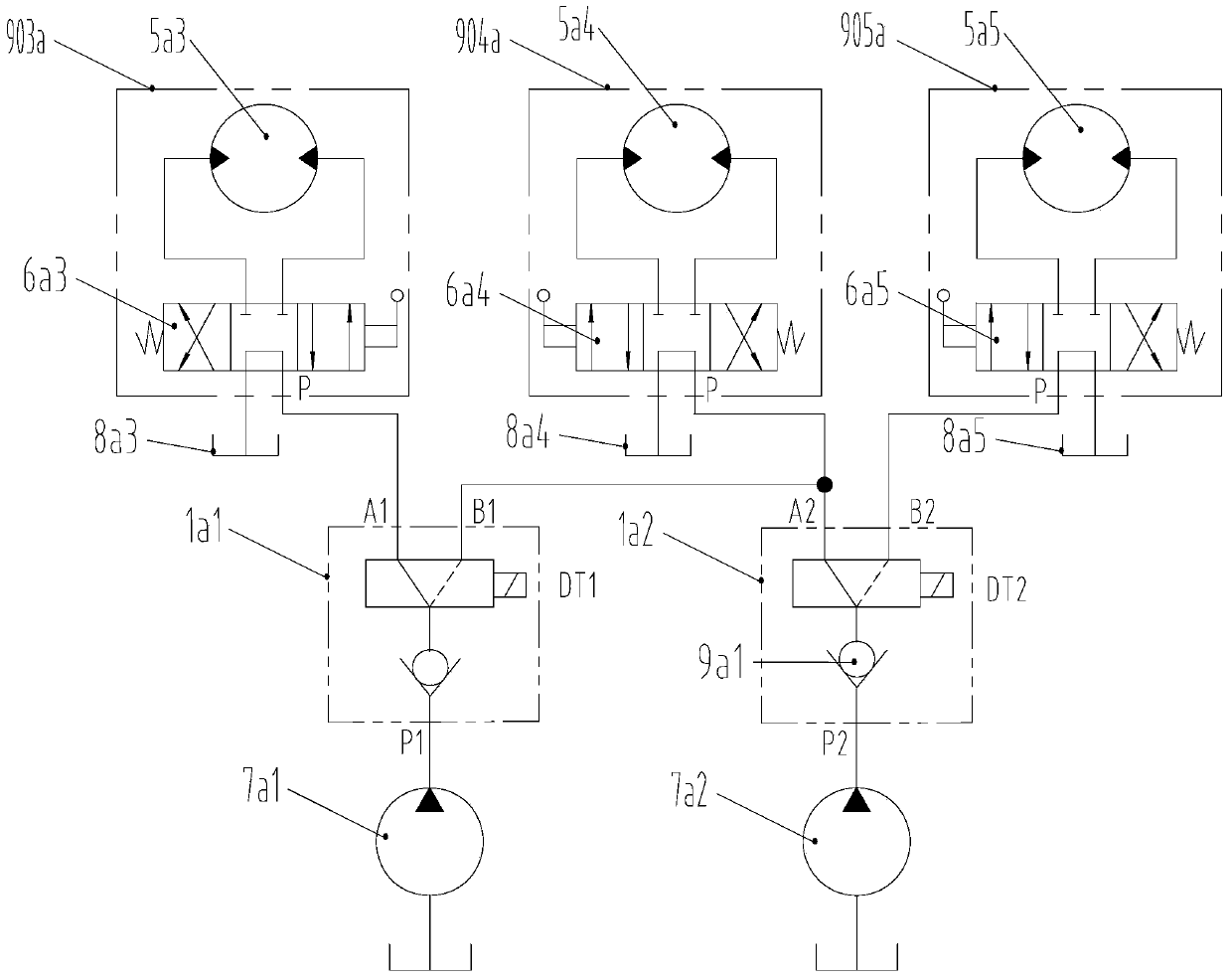

[0045] The embodiment of the present invention provides another electro-hydraulic control system. Compared with the second embodiment, this embodiment is equipped with two hydraulic pumps, three actuators and two electro-hydraulic control reversing valves.

[0046] Such as image 3 As shown, when there are three actuators and they are respectively the third actuator 903a, the fourth actuator 904a and the fifth actuator 905a, there are two hydraulic pumps and they are respectively the first hydraulic pump 7a1 and the second hydraulic pump 7a2 , there are two electro-hydraulic control reversing valves, which are respectively the first electro-hydraulic control reversing valve 1a1 and the second electro-hydraulic control reversing valve 1a2, the third actuator 903a includes a motor 5a3 and a manual reversing valve 6a3, and the manual reversing valve The A port of the directional valve 6a3 is connected with the A port of the motor 5a3, the B port of the manual directional valve 6a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com