Full-unloading disc type magnetic pole large-drift-diameter two-position three-way electromagnetic valve

A two-position three-way, large-diameter technology, used in multi-way valves, lift valves, valve details, etc., can solve the problems that affect the response performance of high-thrust engines, limit the capacity of intake and exhaust channels, structural size and weight, etc. Achieve the effect of improving magnetic efficiency, light structure and high applicable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and exemplary embodiments.

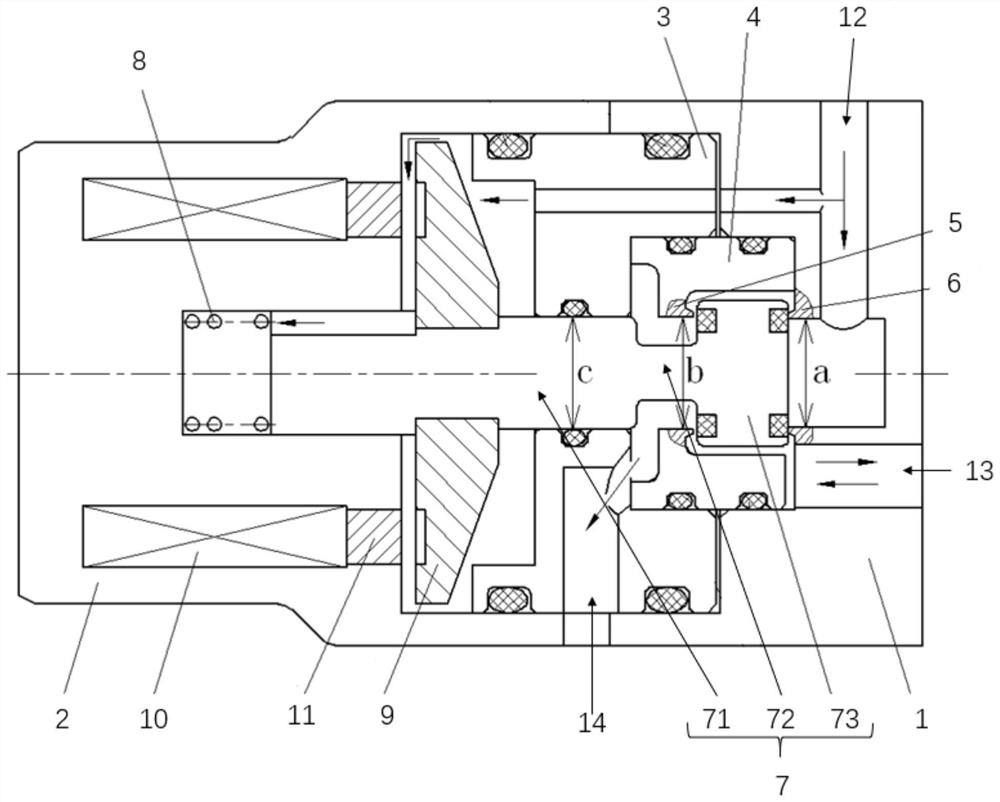

[0025] refer to figure 1 , the present invention provides a two-position three-way solenoid valve with a full unloading disc type magnetic maximum diameter, including a valve body 1, an electromagnetic housing 2, an outer lining ring 3, an inner lining ring 4, an exhaust valve seat 5, and an intake valve Seat 6, spool rod 7, return spring 8, magnetic disk 9 and coil 10; Described valve body 1 is docked with electromagnetic housing 2 to form a first chamber, and outer lining ring 3 is arranged in the first chamber, and outer lining ring 3 and A second chamber is formed between the valve body 1, and a third chamber is formed between the outer lining ring 3 and the electromagnetic housing 2; the inner lining ring 4 is arranged in the second chamber, and the inner wall of the inner lining ring 4 is radially An annular protruding exhaust valve sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com