Compressor stator cascade with blade root provided with equal-width broken line shaped channels

A technology of compressor and sub-leaf cascade, which is applied to the flow control scheme of the blade root slotting of the compressor stator blade cascade, the flow control of the compressor stator blade cascade, and the passive flow control field, which can solve the problem that the control scheme is difficult to optimize the design and the direction of the jet velocity. Uncontrollable, poor processing and other problems, to achieve the effect of good corner separation inhibition, easy to optimize the design, and the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

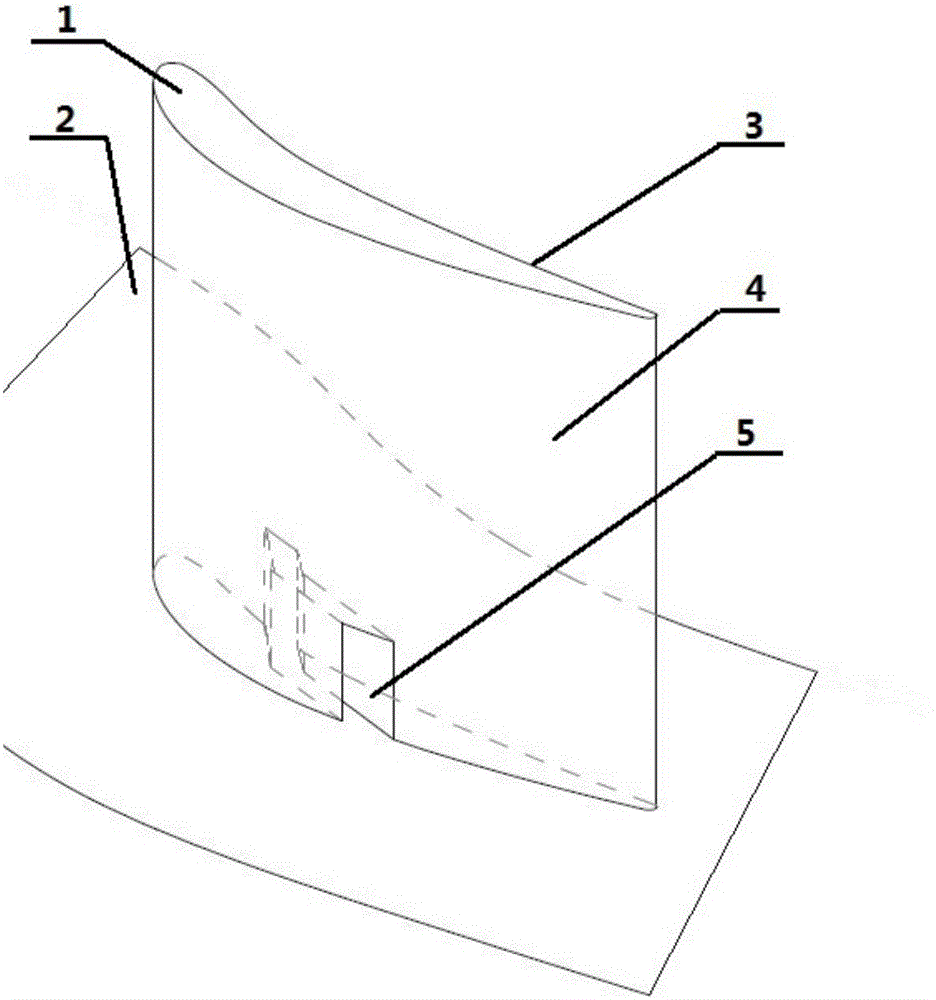

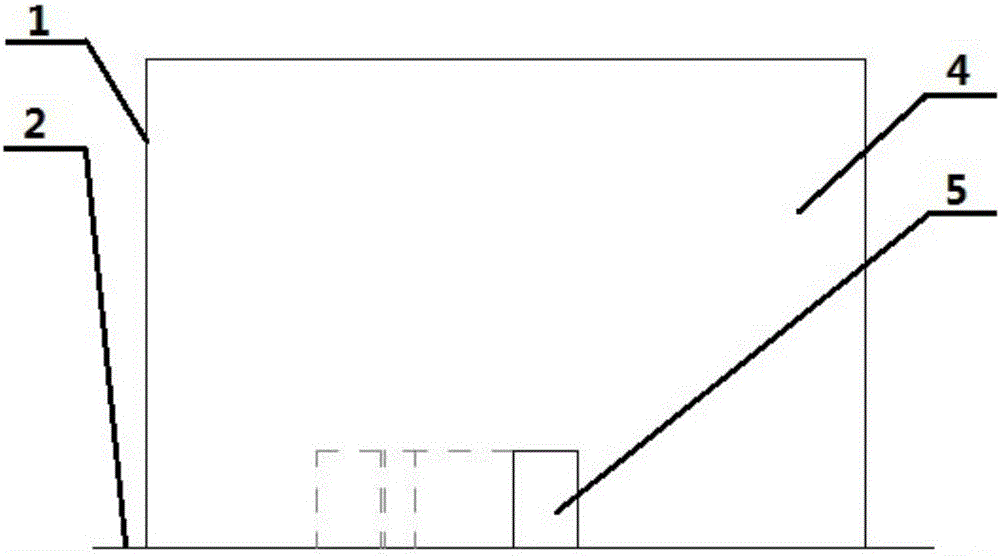

[0023] Such as figure 1 As shown, the stator blade cascade of a compressor with equal-width broken-line grooves in the root of the blade is provided with equal-width broken-line grooves 5 at the end wall 2 of the root of the cascade 1 from the pressure surface 3 to the suction surface 4 of the cascade 1 .

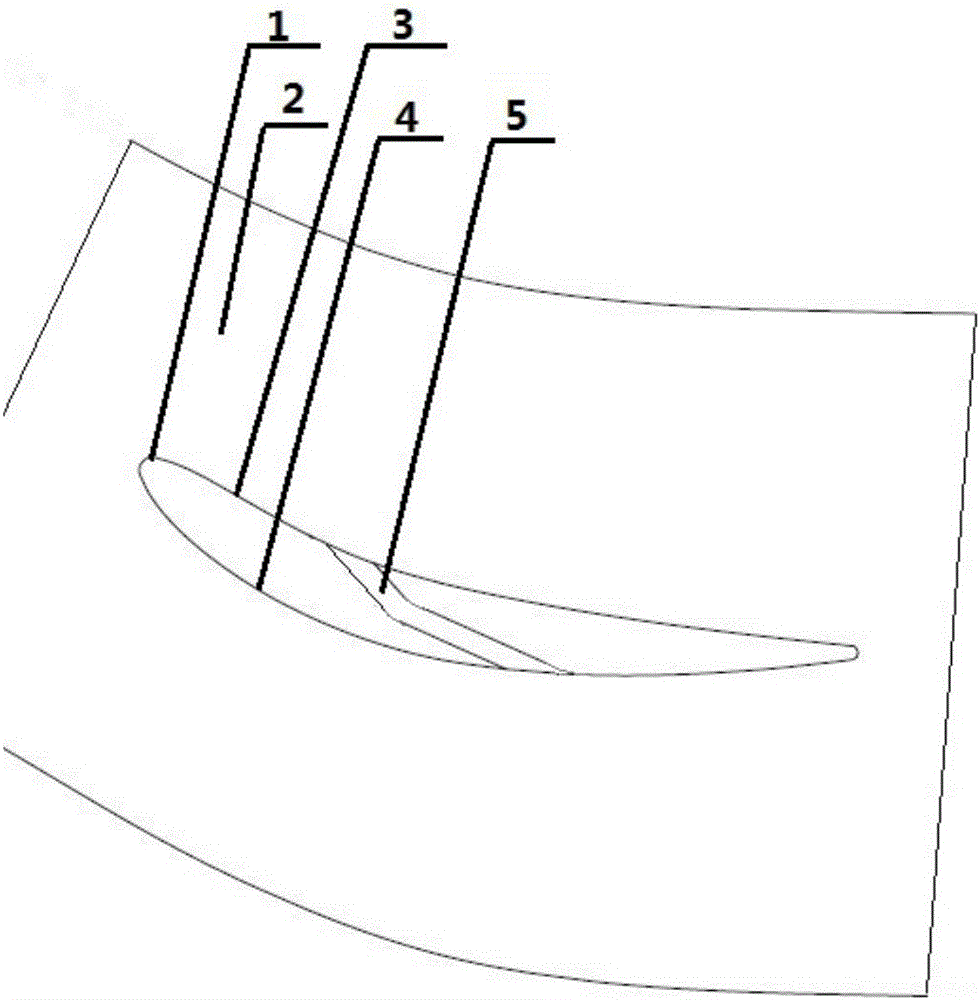

[0024] Such as figure 2 As shown, according to the PVD prototype stator cascade flow field, the position of the outlet of the channel 5 on the suction surface 4 is selected before the separation point; along the axial direction of the cascade, the position of the inlet of the channel 5 on the pressure surface 3 is located on the suction surface 4 Upstream of the outlet position; according to the pressure distribution on the surface of the PVD prototype stator cascade, the position of the inlet of the channel 5 on the pressure surface 3 is selected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com