Electromagnetic drive device and pilot-operated type electromagnetic pneumatic valve

An electromagnetic pneumatic valve, electromagnetic drive technology, applied in the direction of valve device, valve operation/release device, valve details, etc., to improve the response and ensure the effect of reliable implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

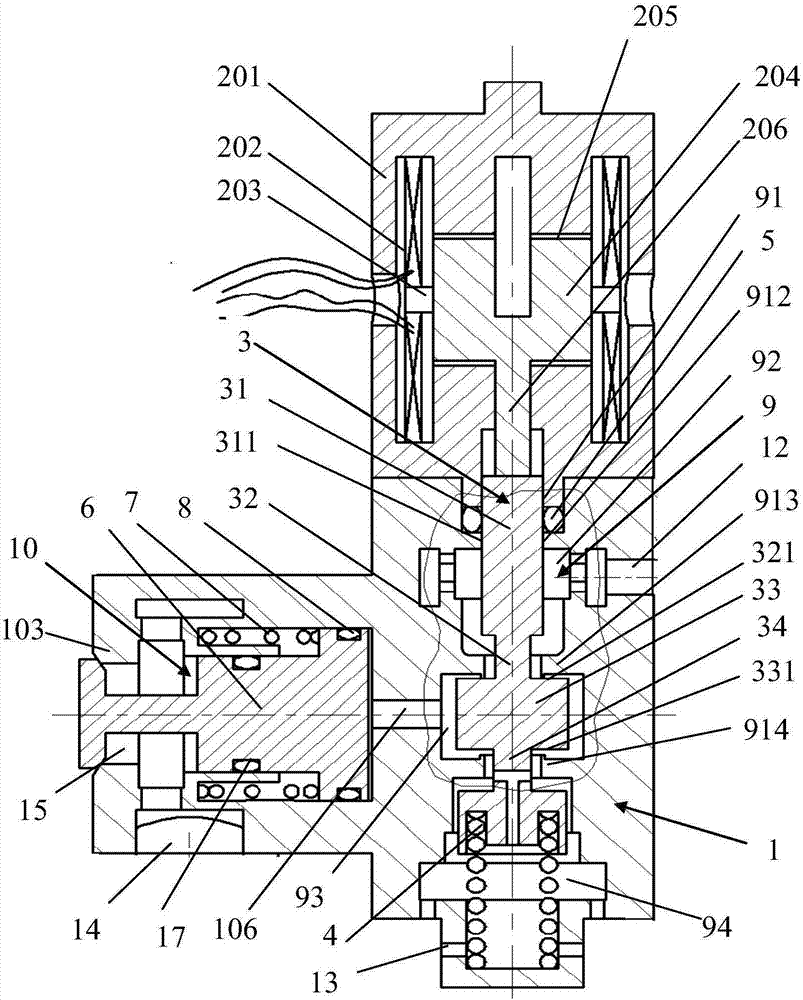

[0027] The present invention is described in detail below in conjunction with the embodiment that accompanying drawing provides:

[0028] see figure 1 , an electromagnetic drive device, including a housing 201, an electromagnetic coil 202, a permanent magnet 203, an armature 204, a magnetic isolation pad 205 and a push rod 206; the electromagnetic coil 202, the permanent magnet 203 and the armature 204 are arranged in the housing 201, and the permanent The magnet 203 is ring-shaped, arranged in the middle of the housing 201, concentric with the housing 201; the electromagnetic coil 202 is concentric with the housing 201, the electromagnetic coil 202 is divided into two sections, and the two sections of electromagnetic coil 202 are respectively arranged on the top of the permanent magnet 203 With the lower part; after the electromagnetic coil 202 is energized, the direction of the magnetic field generated by the electromagnetic coil 202 is opposite to the direction of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com