Testing machine for adjusting durability of car steering column

A steering column and durability technology, applied in the field of automobile steering column adjustment durability performance testing machine, can solve the problems of lack of wide applicability, limitation and single function of the column, achieve scientific and fair test results, reduce testing costs, The effect of reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

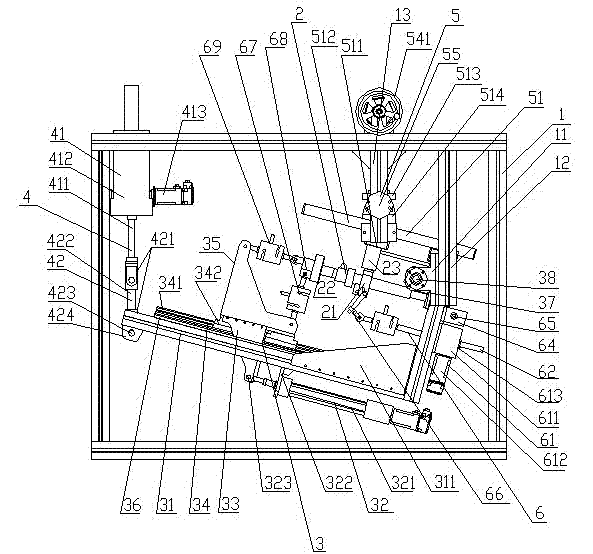

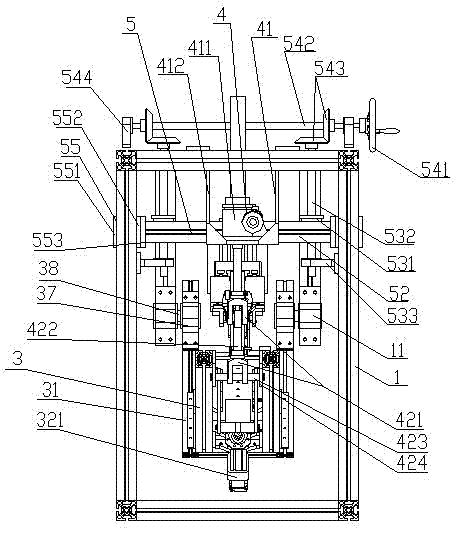

[0022] Embodiment one: see figure 1 , the automobile steering column adjustment durability test machine, including the test bench frame 1, the tested column assembly 2, the axial adjustment device 3, the radial adjustment device 4, the adjustable clamping device 5, the unlocking device 6, And a data acquisition and processing system; it is characterized in that: the radial adjustment device 4 is fixedly connected on the test bench frame 1, one end of the axial adjustment device 3 is hinged with the test bench frame 1, and the other end is connected with the radial adjustment device 4 through a pin, The pipe string clamping adjustable device 5 is fixed on the test bench frame 1, used to clamp the tested pipe string assembly 2, and adjust the position of the tested pipe string assembly 2, so that the output end of the tested pipe string assembly 2 is in line with the The axial adjustment device 3 is connected, and the unlocking device 6 is installed on the axial adjustment devic...

Embodiment 2

[0023] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0024] The structure of the test bench frame 1 is as follows: a cuboid frame is spliced by aluminum alloy profiles, and two pairs of short profiles are respectively installed on the front and back of the frame. 13 is used to install the adjustable pipe string clamping device 5 .

[0025] The structure of the tested pipe string assembly 2 is as follows: the test piece bracket 23 is fixedly connected to the support of the pipe string test piece 21, and the output end of the pipe string test piece 21 is fixedly connected to the inertial disk 22 which is equivalent to a steering wheel.

[0026]The structure of the axial adjustment device 3 is: two pairs of one long and one short aluminum profiles are fixed vertically, and are respectively fixed to the two ends of an aluminum profile to form an L-shaped bracket 31, and the two sides of the L-shaped bracket 31 Ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com