Hydraulically controlled two-way reversing valve, load holding module and load holding system

A load-holding, reversing valve technology, applied in multi-way valves, valve devices, valve details, etc., can solve problems such as pipe bursting, poppet valve core breakage, inaccurate positioning, etc., and achieve the effect of simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

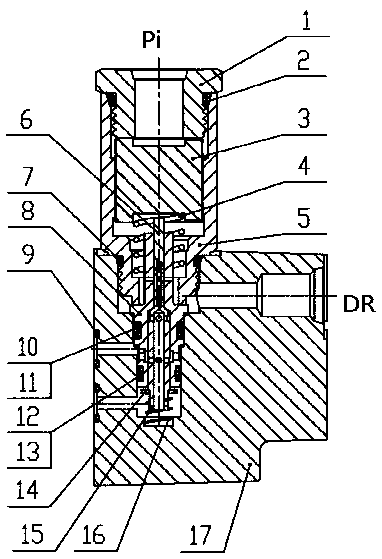

[0043] to combine figure 1 As shown, a hydraulically controlled two-way reversing valve, the end cover 17 is square, the upper end surface of the end cover 17 is provided with a vertically downward step installation hole, and the left side of the end cover 17 is provided with an oil passage connected to the step installation hole a. Oil passage b, the right side of the end cover 17 has an oil passage DR connected to the step mounting hole.

[0044] The lower end of the valve body Ⅰ5 is provided with external threads, and the outer end of the stepped mounting hole of the end cover 17 is provided with external threads. An O-ring III7 is installed between the bodies I5. A stepped hole is opened at the center of the valve body I5, and a valve seat 1 and a cover gasket 3 are installed in sequence from outside to inside in the stepped hole of the valve body I5. The shaft center of the valve seat 1 is provided with an oil passage Pi passing through the valve seat 1. The lower end ...

Embodiment 2

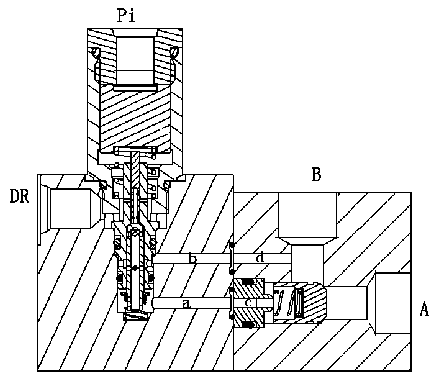

[0049] On the basis of the first embodiment above, combined with Figure 2 to Figure 4 As shown, the load holding module is mainly composed of a hydraulically controlled two-way reversing valve and a holding valve.

[0050] The holding valve includes a square body II18. There are oil passages c and d on the left side of valve body II18, oil passage B is opened on the upper side of valve body II18, and oil passage A is opened on the right side of valve body II18. The inner end of oil passage d is connected with the middle part of oil passage B, and the inner ends of oil passage c, oil passage A and oil passage B intersect.

[0051] Oil passage c is a stepped hole, and cover plate 21, spring III 20, and retaining spool 19 are installed sequentially in oil passage c from outside to inside. The circumferential surface of the cover plate 21 is connected with the inner wall of the oil passage c, and the circumferential surface of the cover plate 21 is provided with a mounting groo...

Embodiment 3

[0054] On the basis of the above-mentioned embodiment two, combining Figure 5 As shown, the load holding system includes a load holding module, a multi-way valve and a boom cylinder. The A1 port of the multi-way valve is connected to the oil passage A of the load holding module; the oil passage B of the load holding module is connected to the large chamber of the boom cylinder, the oil passage DR of the load holding module is connected to the fuel tank, and the oil passage Pi of the load holding module is connected to the multi-channel The pilot pressure oil passage of the lower position of the valve; the small cavity of the boom cylinder is connected to the B1 oil port of the multi-way valve.

[0055] Lifting condition of the boom cylinder:

[0056] The boom cylinder rises, that is, the rising position of the multi-way valve gives pilot pressure, the principle of the multi-way valve moves to the right, and the pressure oil flows from the P port of the multi-way valve throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com