Composite tensioning device

A tensioning device and sliding bearing technology, which is applied in the field of new composite tensioning devices, can solve the problems of hidden safety hazards, low efficiency, and high labor intensity, and achieve the effects of long component life, high efficiency, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

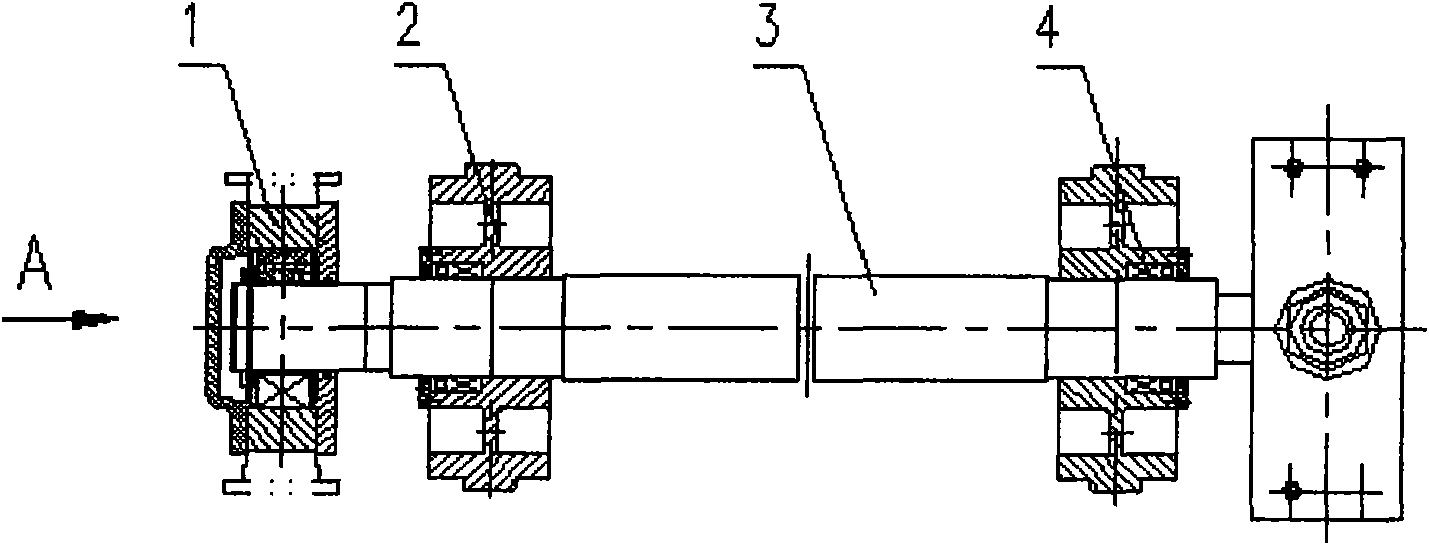

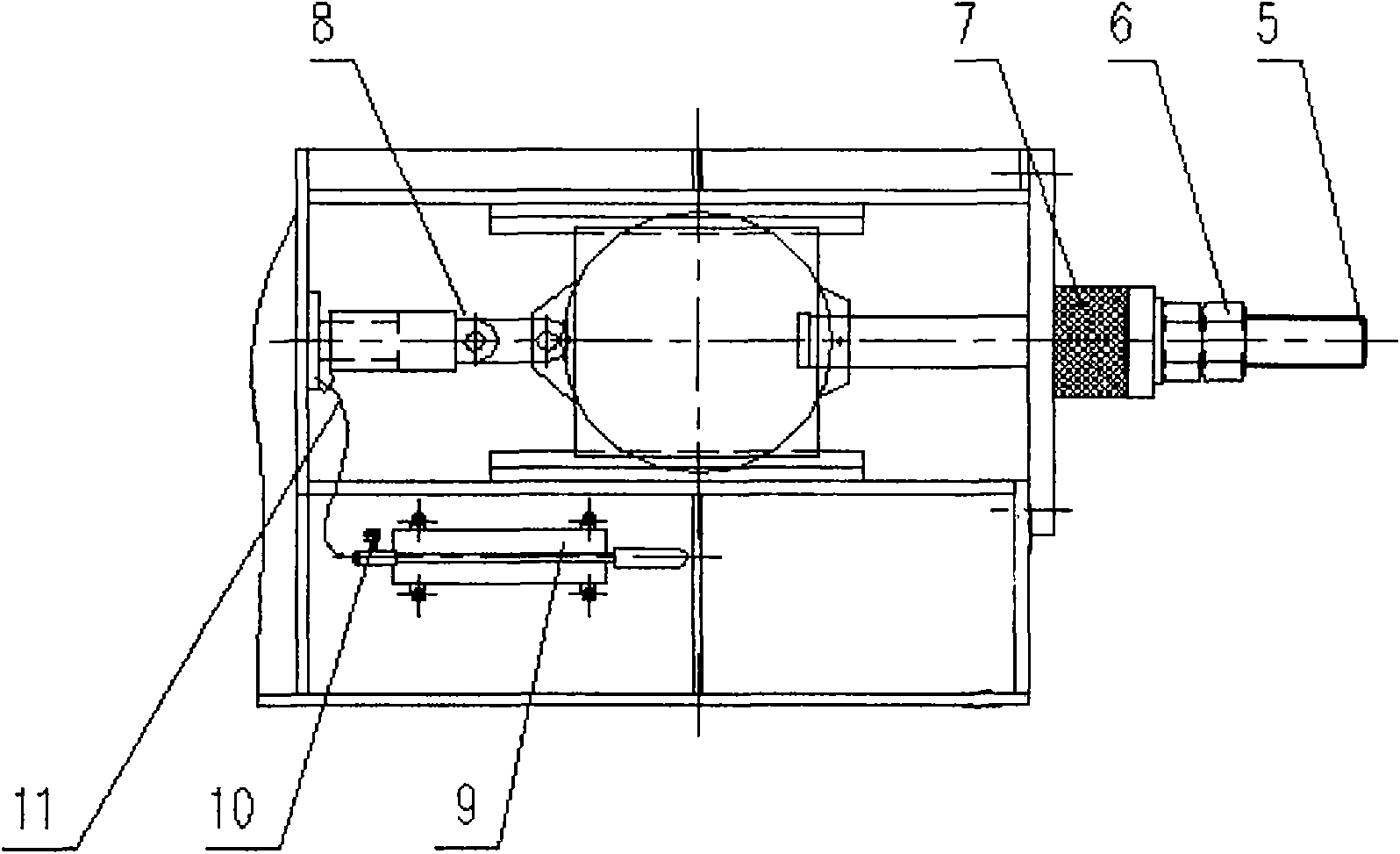

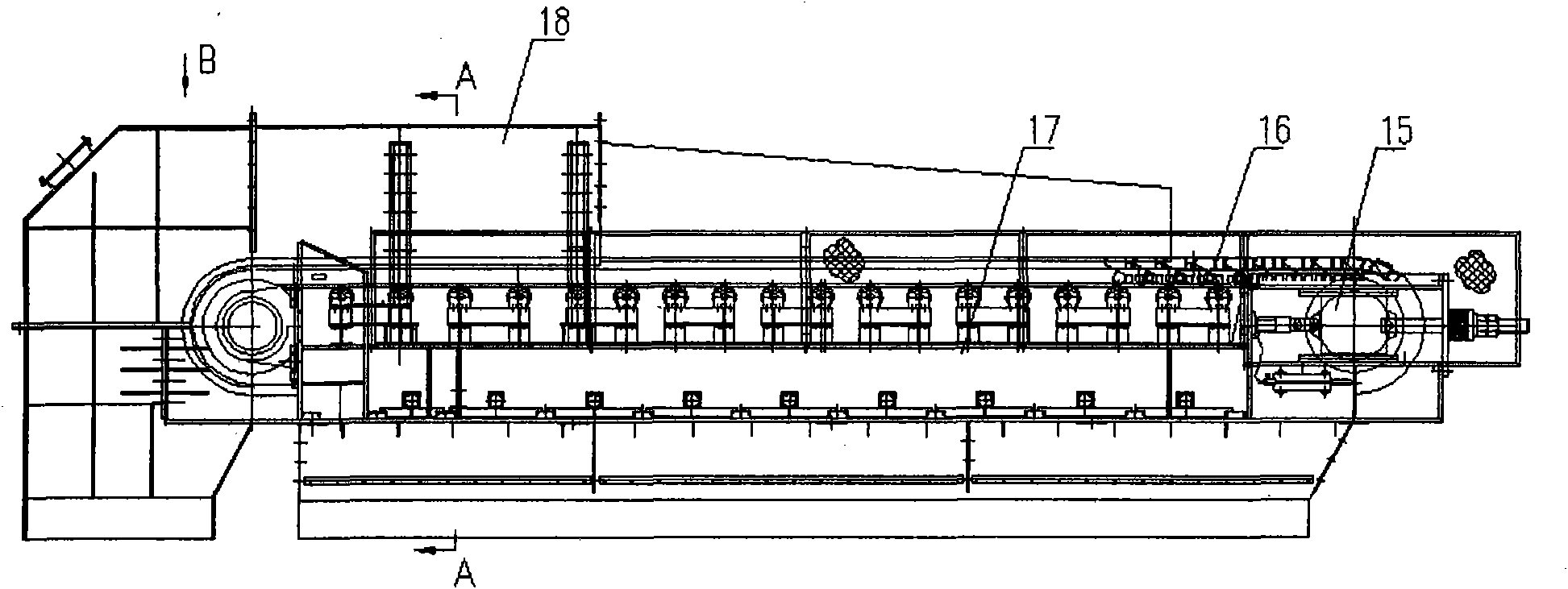

[0015] Referring to the accompanying drawings, a composite tensioning device, the whole device consists of a sliding bearing seat 1, a support wheel 2, a tensioning shaft 3, an expansion sleeve 4, a screw rod 5, a nut 6, a composite spring 7, an oil cylinder 8, a manual oil pump 9, Composed of a pressure gauge 10 and a pipeline 11, the sliding bearing seat 1, the supporting wheel 2, and the expansion sleeve 4 are installed on the tension shaft 3, and are installed on the tail frame, and the supporting wheel 2 supports the chain 24 on the chain plate device 16. , the front of the sliding bearing seat 1 is hinged with the oil cylinder 8, the base of the oil cylinder 8 is welded on the tail frame, the back of the sliding bearing seat 1 is connected with the screw rod 5, and the screw rod 5 passes through the tail frame through the composite spring 7, the nut 6 Tighten; the operation method of the composite tensioning device is to press the left and right sides of the handle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com