Temperature accurate control device and method of oilfield negative-pressure heating furnace

A precise control and temperature control technology, applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of lack of synchronous start and stop, exhaust gas temperature monitoring, liquid and gas leakage protection functions, affecting oil field production , liquid temperature fluctuations and other problems, to reduce the impact of environmental factors, avoid overheating damage, and improve combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

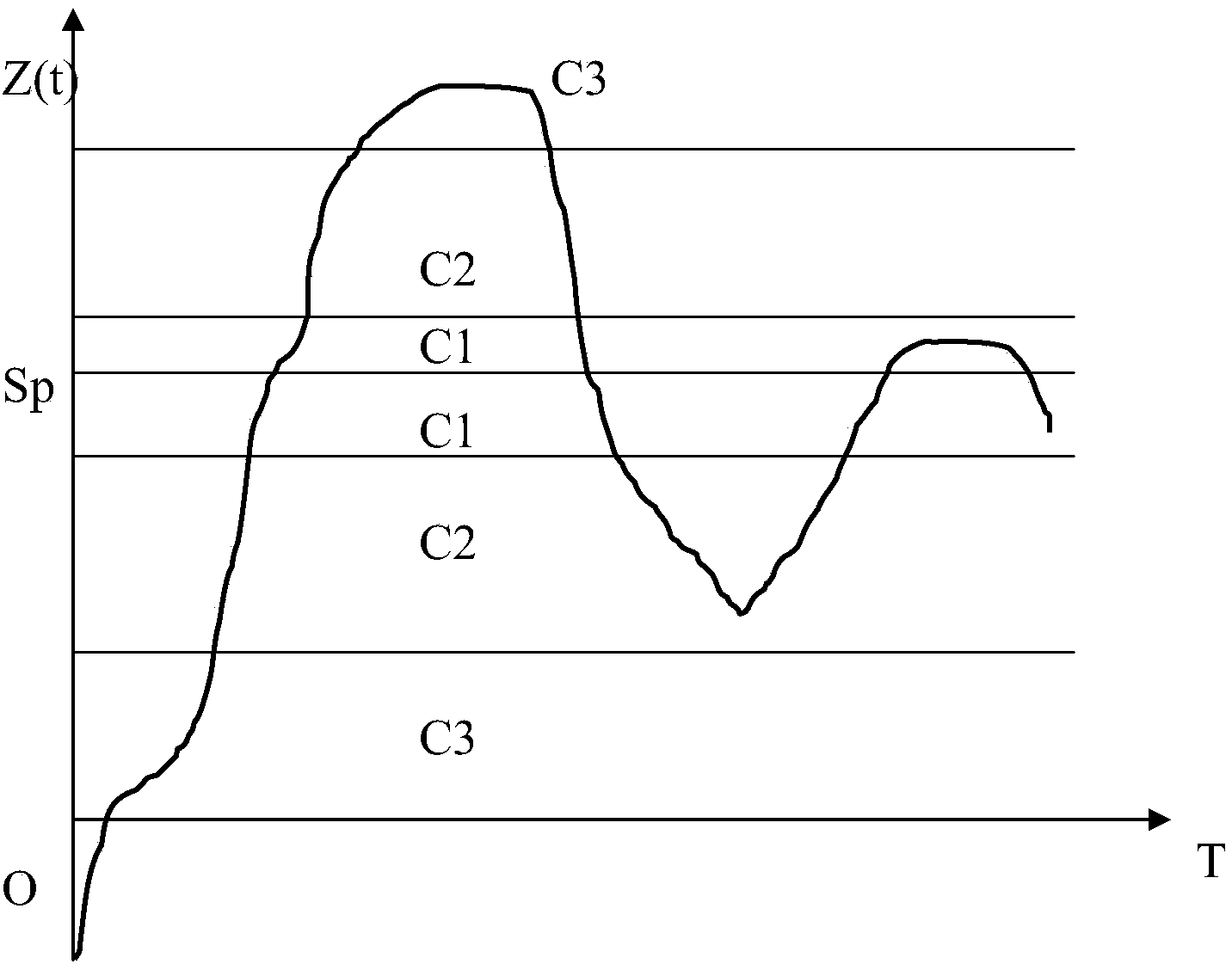

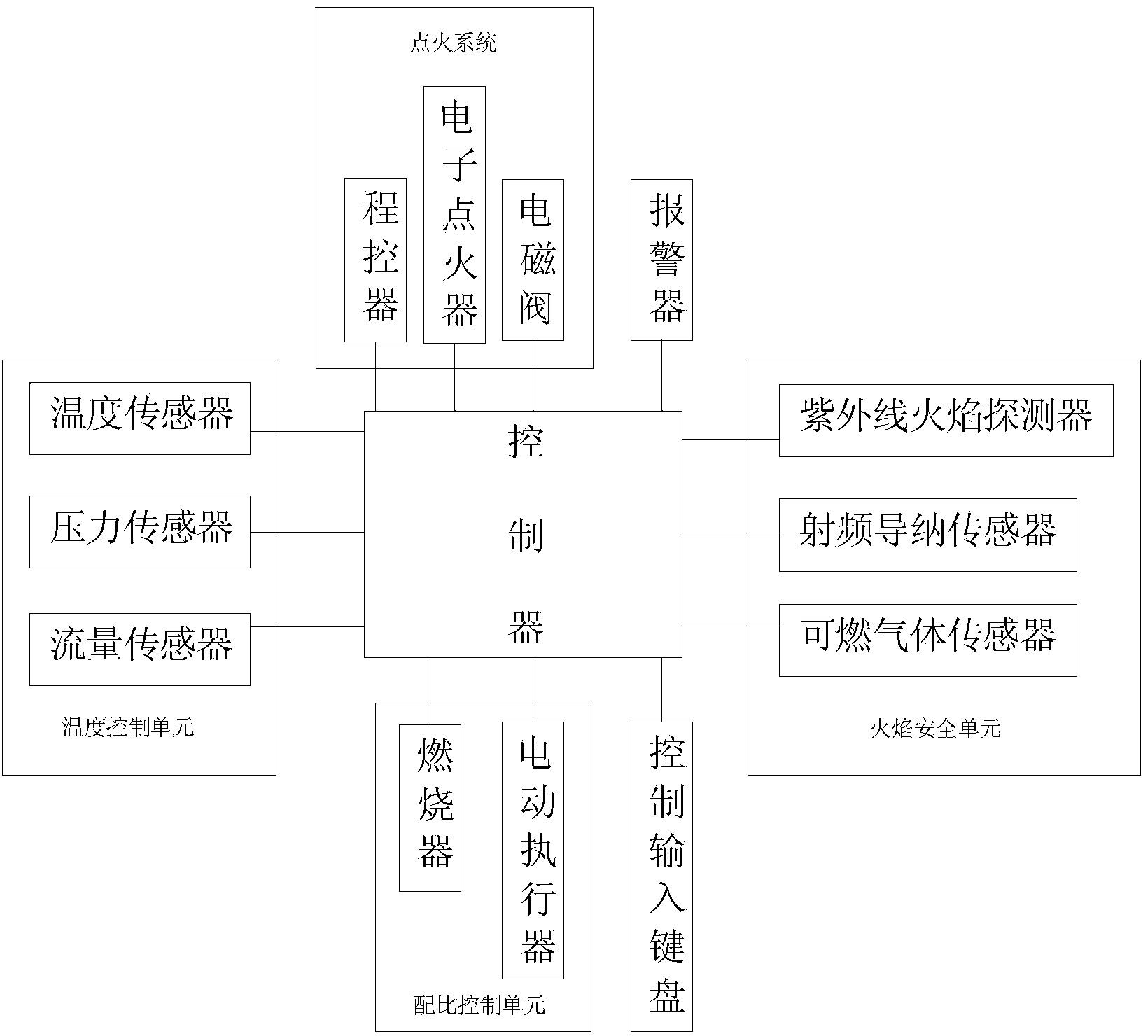

[0017] Embodiment 1: The precise temperature control device of the oil field negative pressure heating furnace, including a controller for collecting relevant data and controlling the operation of each component; the controller is respectively connected with the temperature control unit, the proportioning control unit, the ignition system and the flame The safety unit is connected, and the temperature control unit includes a temperature sensor, a pressure sensor and a flow sensor, wherein the temperature sensor is used to detect temperature data, the pressure sensor is used to collect pressure data such as air pressure, and the flow sensor is used to detect the flow data of the pipeline, and the The data are respectively provided to the controller; the ratio control unit includes a burner and at least one electric actuator installed on the damper, the burner is used to make the fuel and air spray out in a certain way for mixed combustion, and the electric actuator is used to con...

Embodiment 2

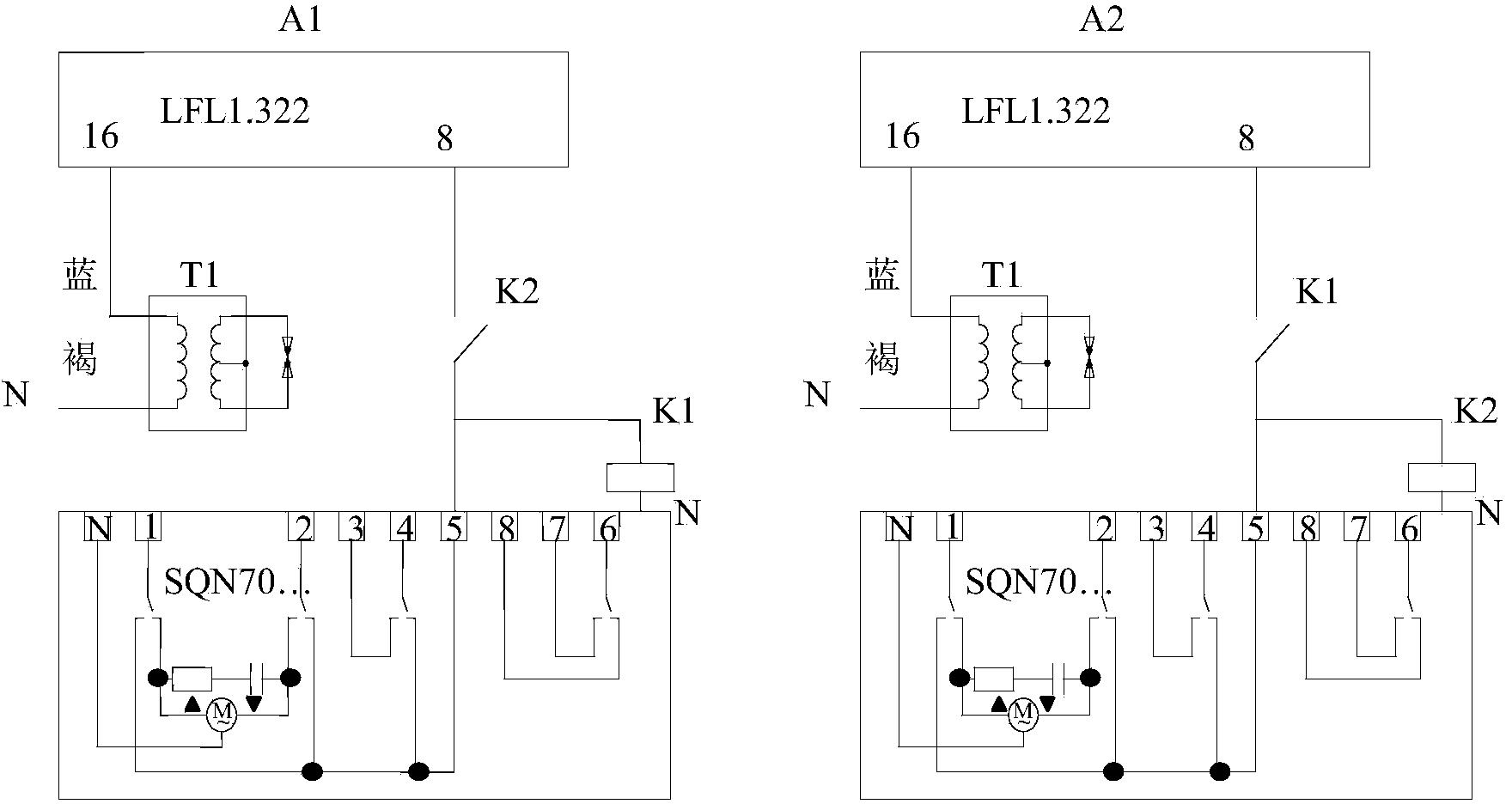

[0018] Embodiment 2: Further, combine image 3 To illustrate this embodiment, when the device is used in an oilfield negative-pressure double-flame heating furnace, the device can be protected by a synchronous dual-control method, that is, there are two electronic valves, which are respectively installed in the oilfield negative-pressure double-flame heating furnace. In the heating furnace pipeline, and the two electronic valves are connected to the controller through an interlock circuit, and the ultraviolet flame detectors are two single-flame detectors that respectively detect the two single-flame furnaces in the negative pressure double-flame heating furnace in the oil field; once the single-flame If the ignition fails or the combustion process goes out and gas leaks, there is a safety hazard of deflagration. The synchronization of the solenoid valve and the ignition process can be realized through interlocking. During the operation, the system uses the ultraviolet flame de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com