3D printing method based on APP big-data modeling and control system

A 3D printing and control system technology, applied in the field of 3D printing, can solve the problem of no molding, reduce waste, prolong the life of the machine, realize the effect of parameter setting and data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

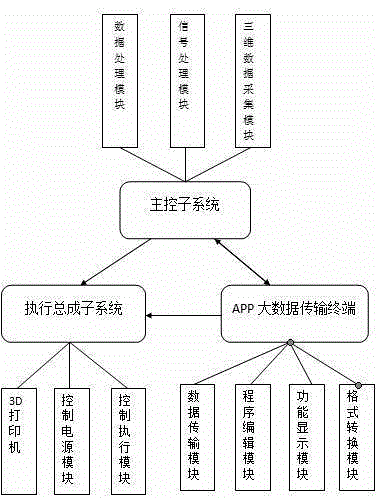

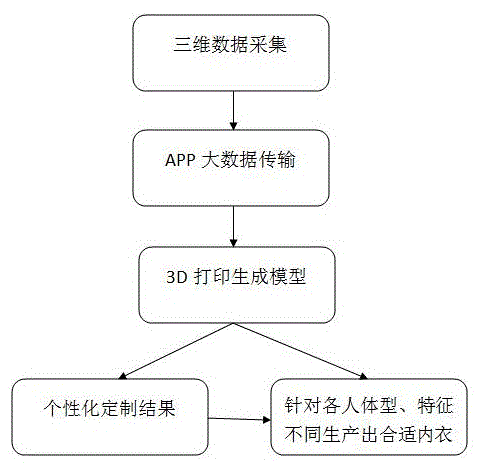

[0023] see figure 1 and figure 2 , whose method includes the following steps:

[0024] (1) Set up a processing device, which is composed of a control system, an electric drive system, a detection system, a 3D printing system and a 3D data information collection system;

[0025] (2) Set up an APP big data transmission terminal in the 3D data information collection system, use the control program to carry out simulated processing and analysis, then transmit it to the 3D printing system, and build a model; for embossed products that are difficult to process, the The APP big data transmission terminal analyzes the physical data of the machine in advance, and judges the key parameters such as the feed speed of the machine, the docking of body shape data, the docking of personalized specification data, and special data. Different operating procedures must be simulated in the software to maintain the original Control the processing device with the consistency of the execution par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com