Microcapsule with damage hinting and repairing functions and application thereof in epoxy coating

A technology of microcapsules and epoxy, applied in the direction of microcapsule preparations, epoxy resin coatings, coatings, etc., can solve the problems that the repair effect of epoxy coatings is difficult to be effectively exerted, microcapsules have poor toughness, and are easy to break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

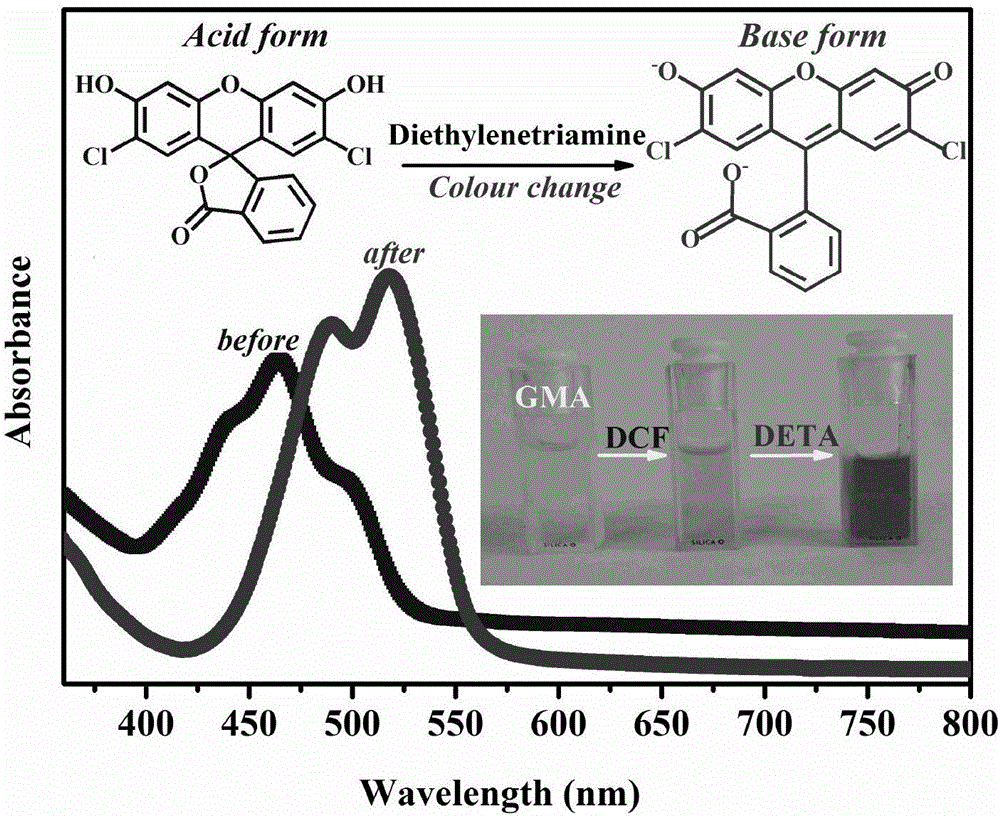

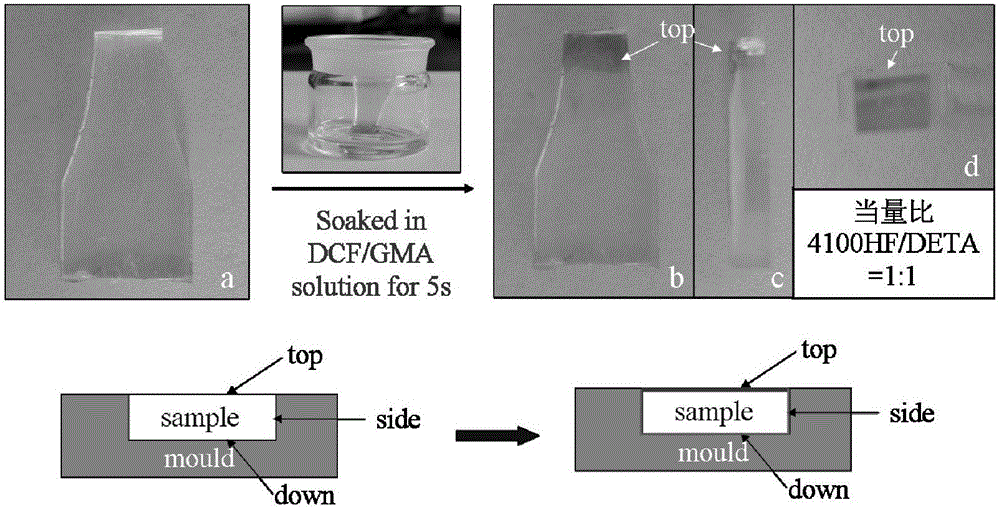

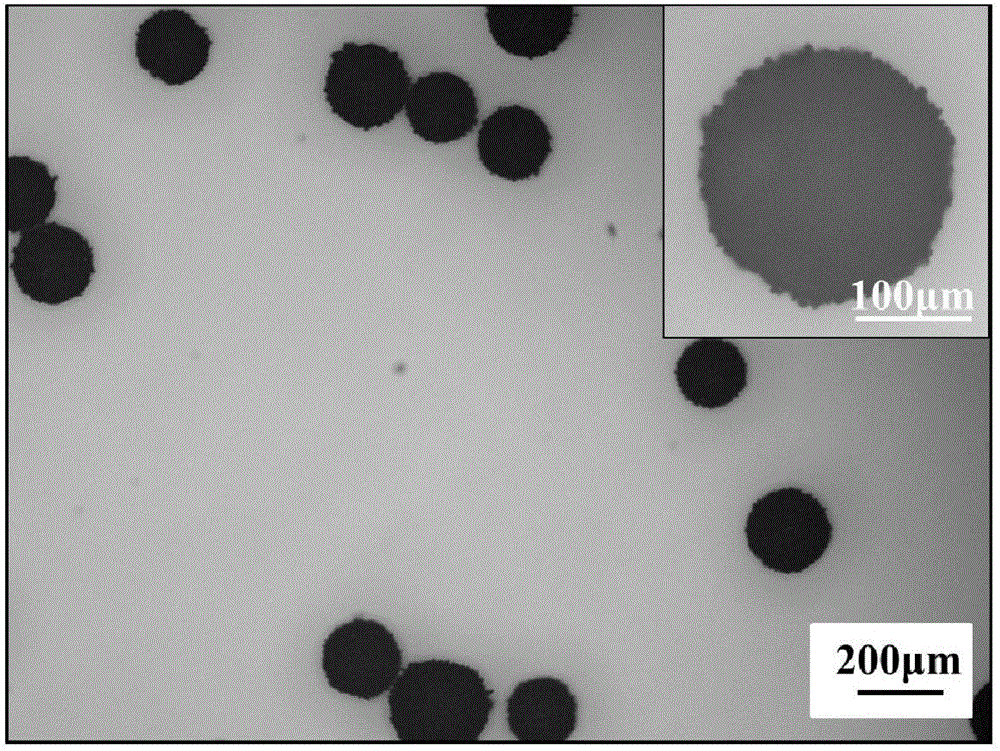

[0055] Dissolve 0.06 g of 2,7-dichlorofluorescein and 4 g of Desmodur L 75 polyurethane prepolymer in 60 ml of glycidyl methacrylate, and ultrasonically disperse for 30 minutes to make a nuclear solution; add 125 ml of deionized In the three-necked flask of water, add 0.625 gram Zemac E400 vinyl maleic anhydride copolymer reactive emulsifier, 3.75 gram urea, 0.25 gram ammonium chloride, 0.375 gram phenol, stir 10 minutes, stirring speed is 400 revolutions per minute, adopt 20wt% sodium hydroxide solution to adjust the pH value to 3.5; then slowly drop the nuclear solution into the three-necked flask, and continue to stir for 10 minutes to complete the pre-emulsification and inner core coating; then slowly raise the temperature to 55±5°C, and slowly add 9.50 Gram 37wt% formaldehyde solution (formalin), insulation reaction 4 hours. The microcapsules are then filtered and rinsed with copious amounts of deionized water to remove excess emulsifier. Finally, dry in an oven at 40±5°...

Embodiment 2

[0057] Dissolve 0.06 g of 2,7-dichlorofluorescein and 2 g of Desmodur L 75 polyurethane prepolymer in 60 ml of ethyl phenylacetate, and ultrasonically disperse for 30 minutes to prepare a nuclear solution; add 125 ml of deionized water to the Add 0.625 gram Zemac E400 vinyl maleic anhydride copolymer reactive emulsifier in the three-necked flask, 2.5 gram urea, 0.25 gram ammonium chloride, 0.25 gram phenol, stir 10 minutes, stirring speed is 400 revolutions per minute, adopt the hydrogen of 20wt% The sodium oxide solution adjusted the pH value to 3.5; then slowly added the nuclear solution dropwise into the three-necked flask, and continued to stir for 10 minutes to complete the pre-emulsification and inner core coating; then slowly raised the temperature to 55±5°C, and slowly added 6.33 grams of 37wt % formaldehyde solution (formalin), heat preservation reaction for 4 hours. The microcapsules are then filtered and rinsed with copious amounts of deionized water to remove exces...

Embodiment 3

[0060] Weigh a certain amount of epoxy resin, diluent, and additives according to the formula and stir it for 10 minutes at a speed of 1000 rpm in the RN-500 revolution and rotation mixing and defoaming machine; then add the curing agent, and then use RN- Stir at a speed of 1000 rpm for 10 minutes in a 500 revolution and self-rotation mixing and degassing machine; Stir at a speed of 1000 rpm for 2 minutes to obtain the epoxy coating premix; finally pour the epoxy coating premix into a vacuum stirring tank and stir for defoaming, the stirring speed is 100 rpm, and the defoaming time For 20 minutes, the vacuum degree is -0.095MPa, and the epoxy coating is obtained.

[0061] Adopt above-mentioned process and method, obtain the epoxy coating product of following 3 formulas (the addition of each component in the formula is in weight fraction) respectively:

[0062] Recipe 1

[0063] Epoxy resin: bisphenol A epoxy resin ADEKA EP-4100HF 100

[0064] Thinner: Polypropylene Glycid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com